Anti-scalding liquid heating container

A liquid heating container, anti-scalding technology, applied in lighting and heating equipment, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as easy scalding of hands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

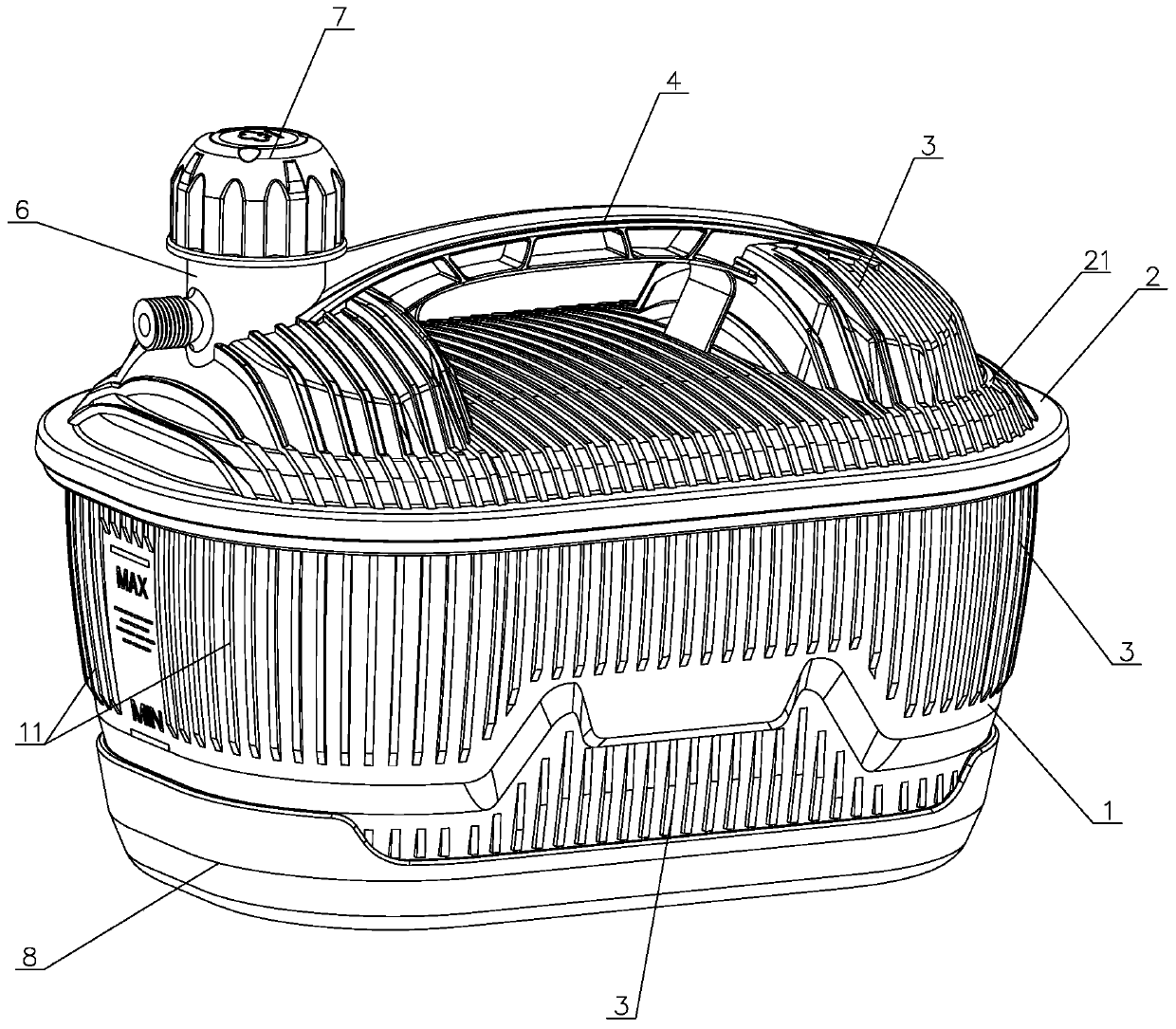

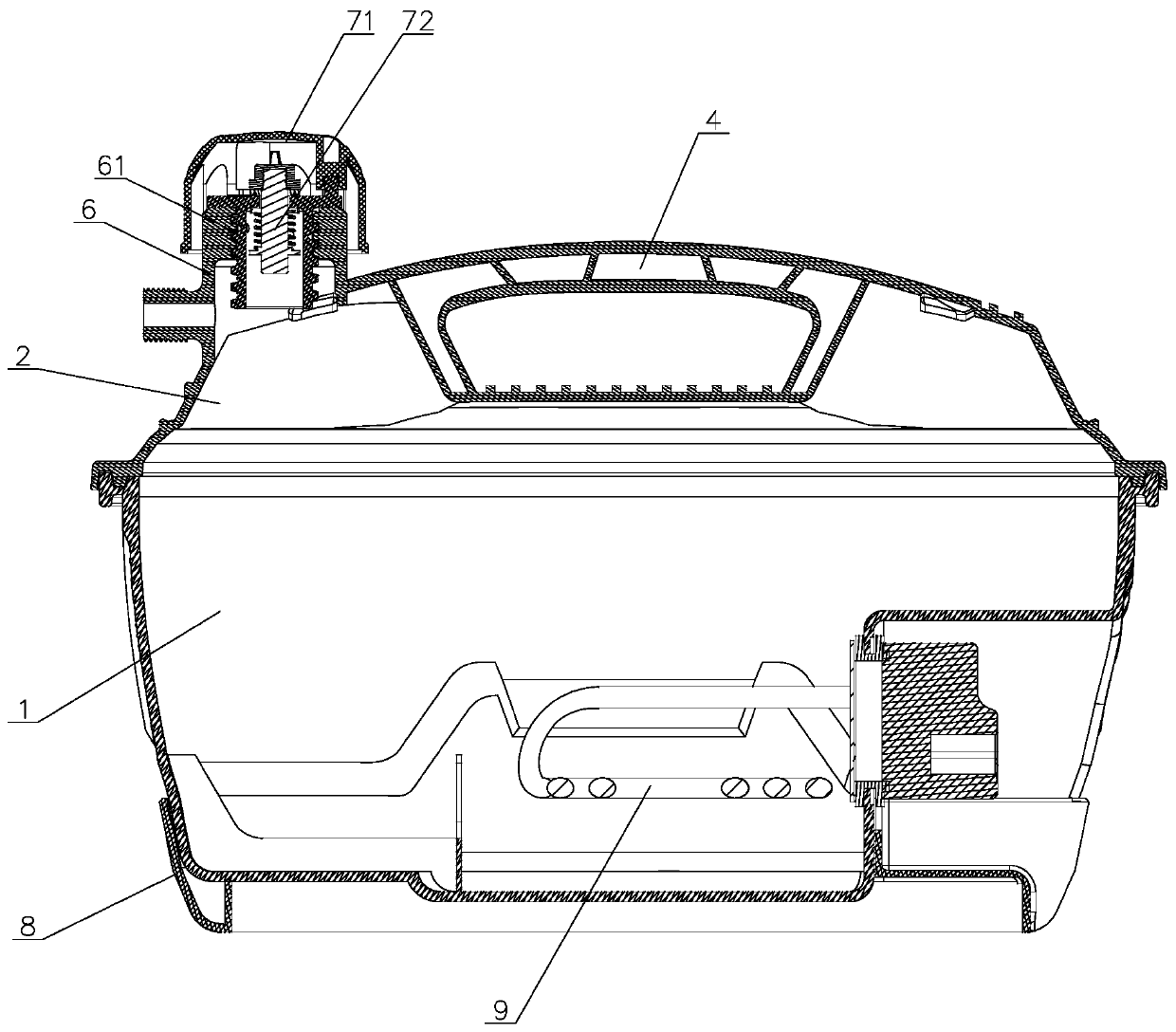

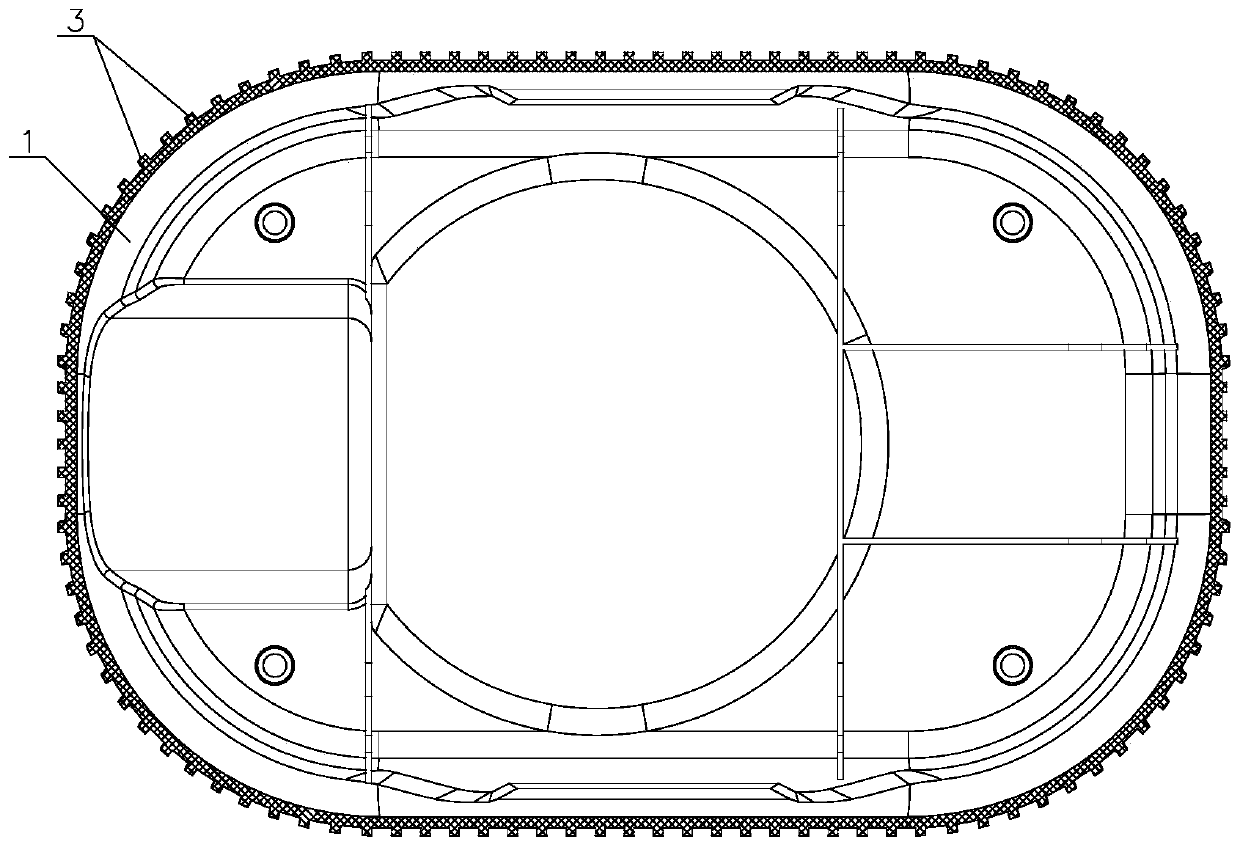

[0023] Such as figure 1 , 2 As shown in , 3 and 4, a liquid heating container capable of preventing scalding is mainly composed of a container body 1 and a container cover 2; wherein, the container body 1 is a housing with an accommodating space for storing liquid, and the container body 1 The bottom installation heating mechanism 9 is used for heating liquid; The upper opening of container main body 1 covers a container cover 2 at the upper opening of container main body 1; The container main body 1 and the container cover 2 can be integrated by welding, or can be fastened and connected by screws.

[0024] On the outer wall of the container main body 1 and the cover surface 21, strip-shaped anti-scald ribs 3 are uniformly and densely distributed, the container main body 1 and the anti-scald ribs 3 are integrally formed, and the cover surface 21 and the anti-scald ribs 3 are integrally formed; 1. The anti-scalding ribs 3 on the outer wall surface are arranged vertically and ...

Embodiment 2

[0029] Compared with Embodiment 1, the difference of this embodiment is that there is no anti-scald lining outside the bottom of the container body 1, but downwardly protruding support feet are provided at the four corners of the bottom surface of the container body 1, There is a gap between the bottom surface of the container main body 1 and the ground.

[0030] According to actual design and appearance requirements, the anti-scalding ribs 3 on the container body 1 and the container cover 2 can be arranged in various other shapes, such as triangular, polygonal, circular, or fan-shaped cross-sections; the anti-scalding ribs 3 It can be in the shape of a straight line or a curved strip, which can be close to the surface or curved and undulating relative to the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com