Crimping surface adaptive crimping machine

An adaptive, crimping machine technology, applied in the field of automation, can solve the problems of defective products, crimping failure, difficult process, etc., to achieve the effect of automatic and efficient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

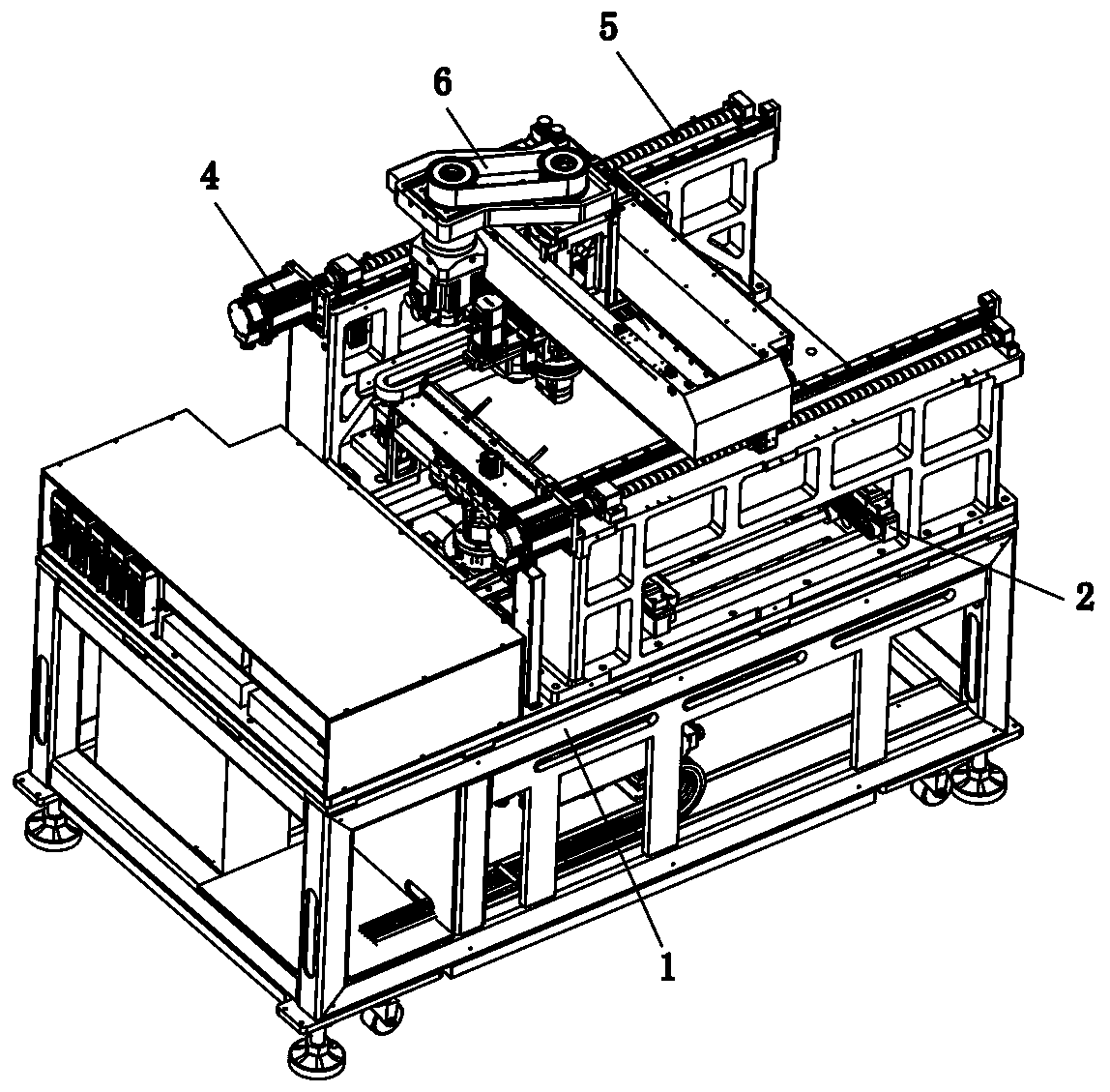

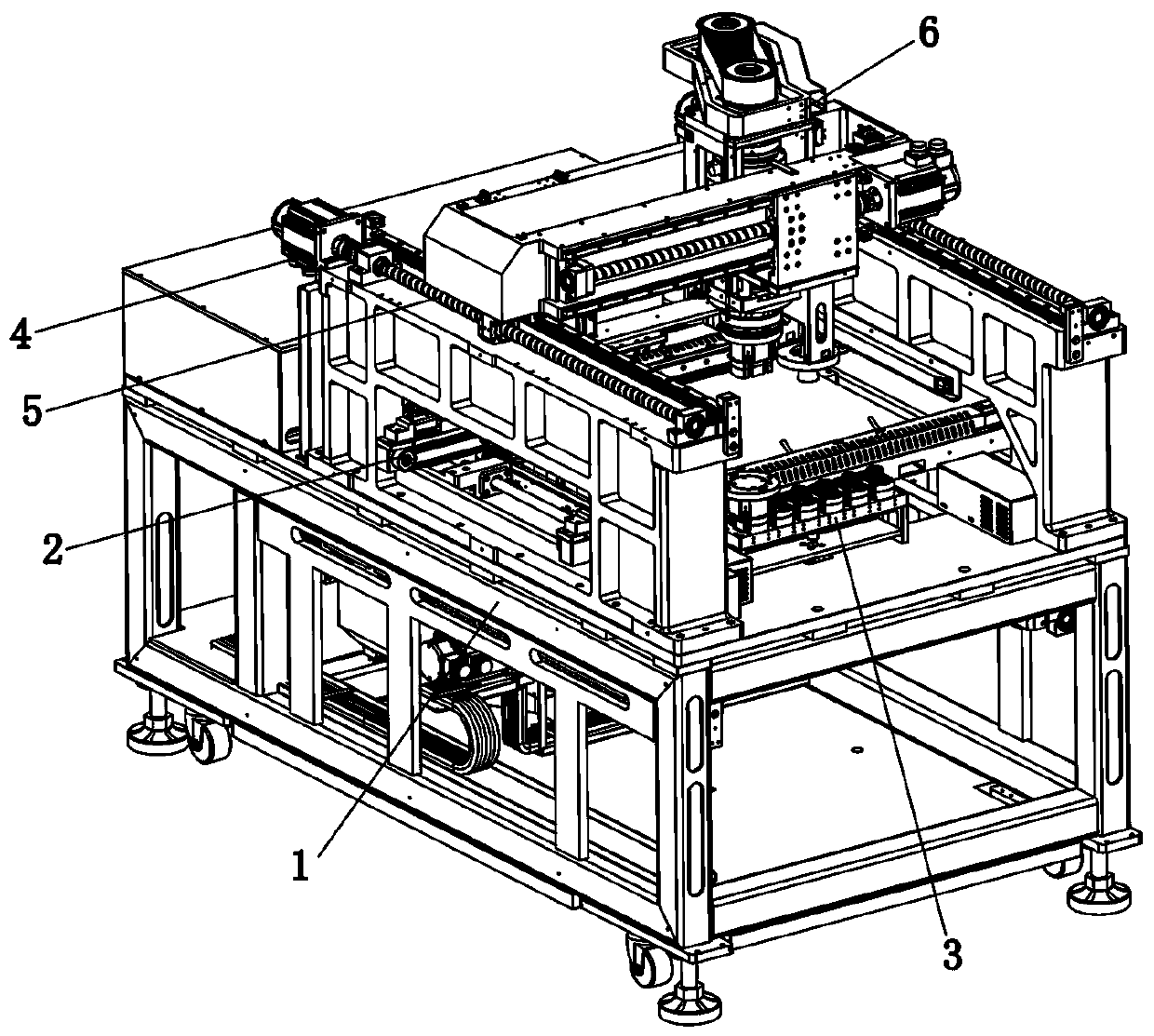

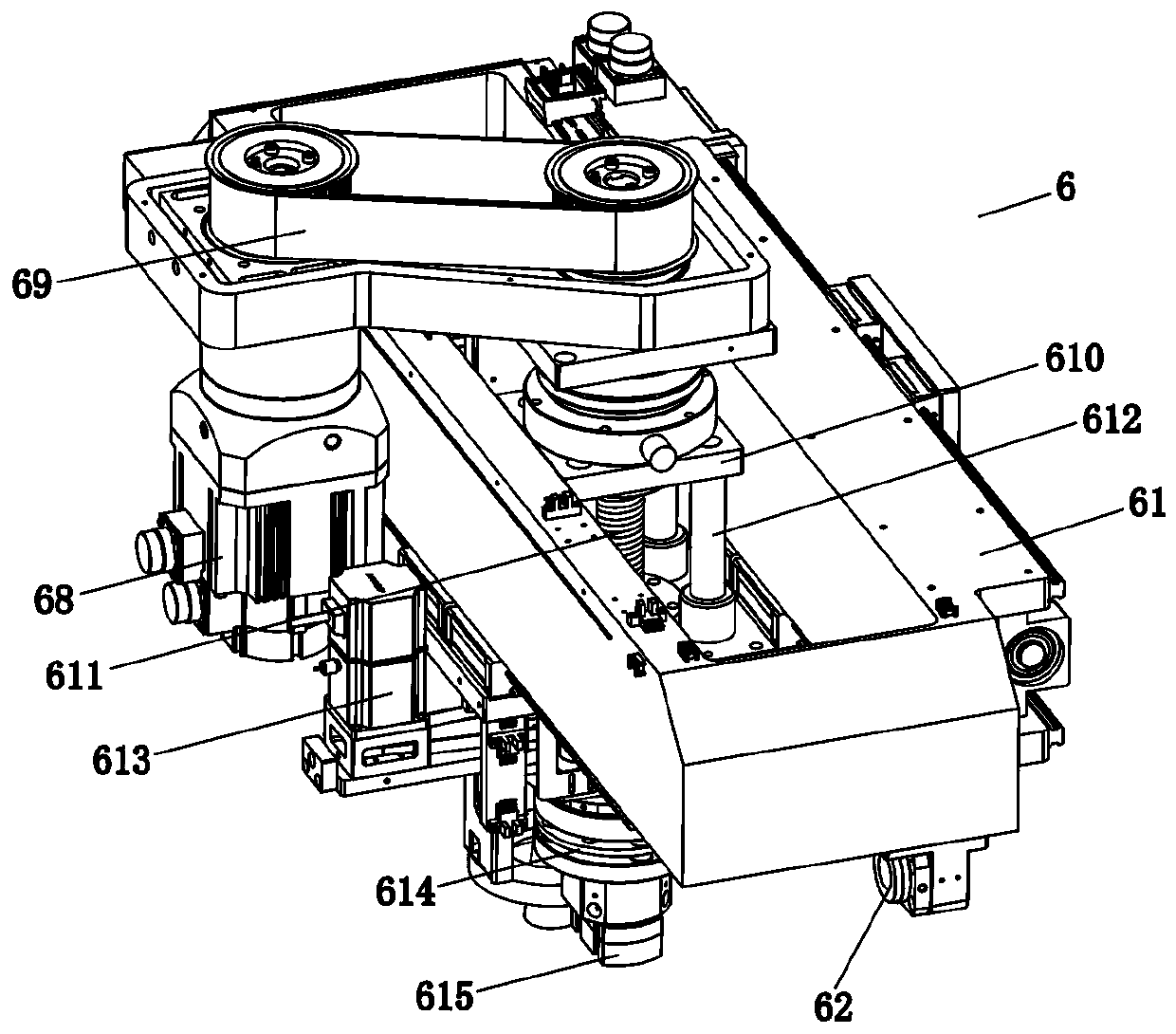

[0040] Embodiment 1: as Figure 1 to Figure 17 As shown, the technical solution adopted in Embodiment 1 of the present invention is as follows: a crimping surface self-adaptive crimping machine, comprising a frame 1 and a conveyor belt 2 arranged on the frame 1. The PCB board, and straightly transport the PCB board forward, also includes a first drive assembly, a crimping mechanism 6 and a replacement mechanism 3, wherein the above-mentioned first drive assembly straddles the transmission belt 2 in a direction perpendicular to the transmission belt 2 The above crimping mechanism 6 is connected to the first drive assembly, and is driven by the first drive assembly to move linearly; the crimping mechanism 6 includes a driving part, a connecting part 614 and a crimping part 615, and the driving part is connected to the first driving assembly On the output end of the drive assembly, the connection part 614 is connected to the output end of the drive assembly, and the drive assembl...

Embodiment 2

[0052] Embodiment 2: as Figure 18 to Figure 20 As shown, compared with Embodiment 1, Embodiment 2 of the present invention simplifies the structure of the crimping mechanism, omits the first transmission belt in Embodiment 1, and the first motor directly drives the rotation of the third screw rod to realize the lifting control function. ; Compared with Embodiment 1, this kind of structural design is simpler, and the production cost of the equipment is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com