Continuous collecting, feeding and extruding integrated device for light wide-width net material

A feeding device and wide-width technology, which is applied in the field of processing equipment for wide-width lightweight mesh materials, can solve the problems of accidental casualties, cumbersome procedures, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

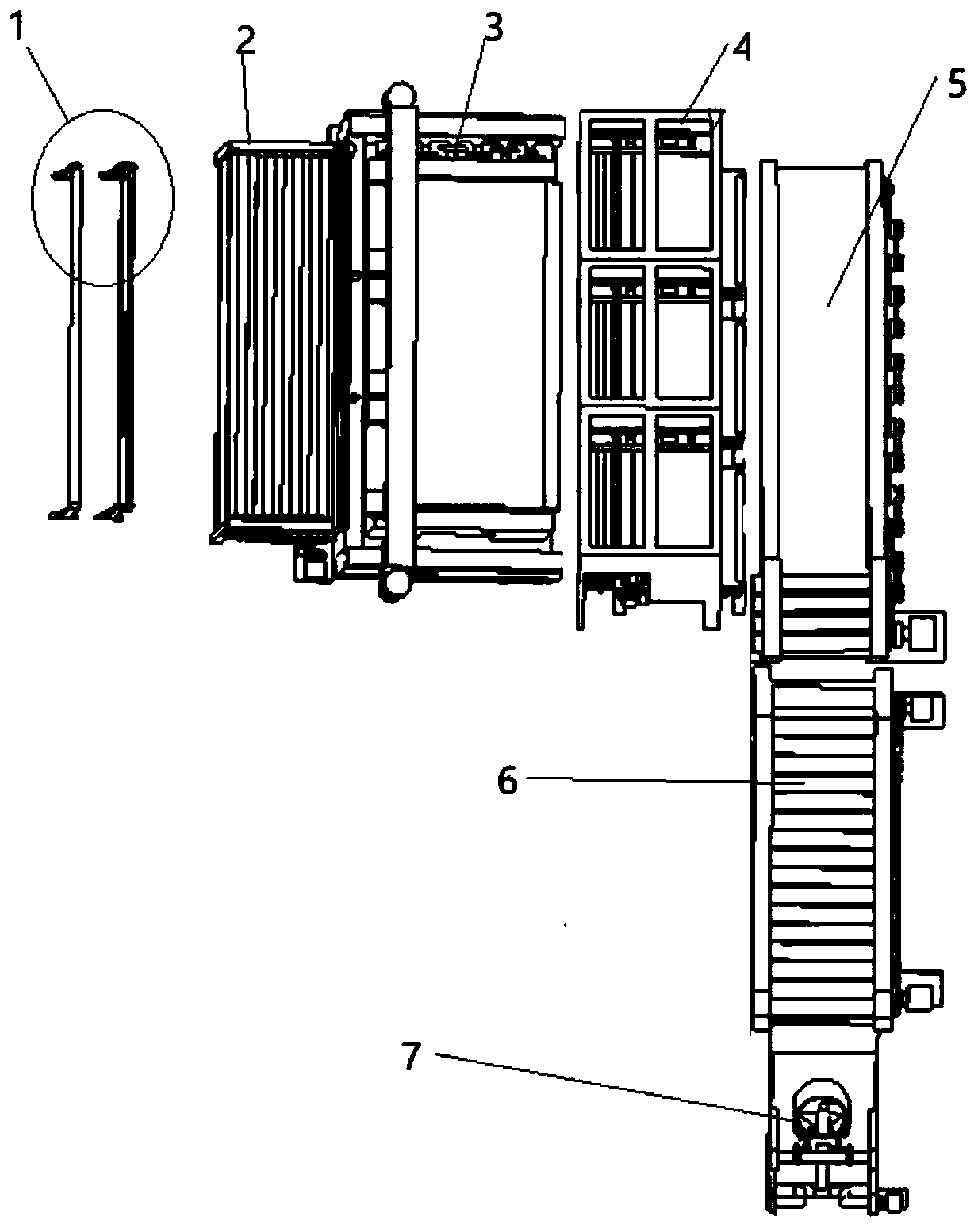

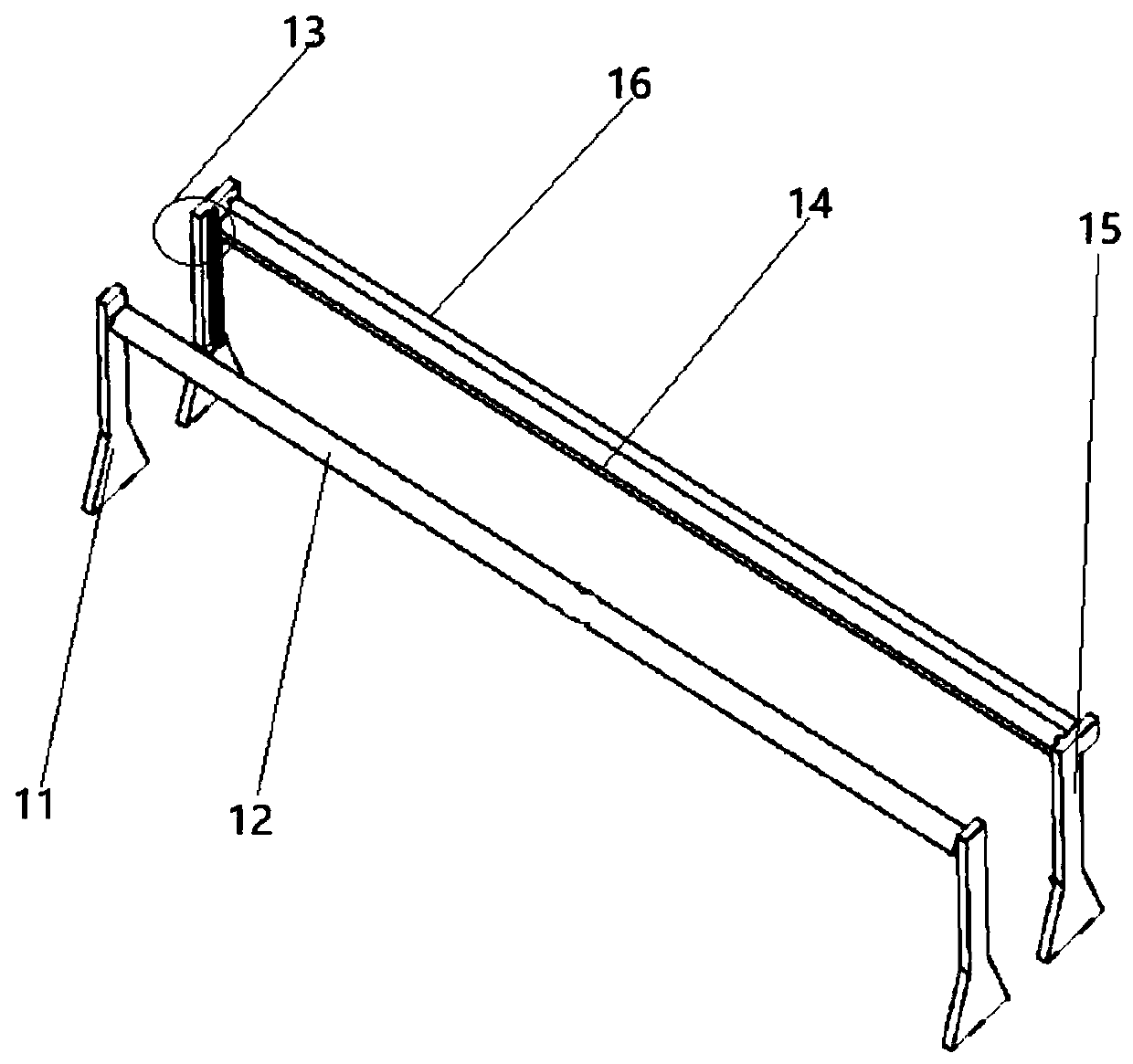

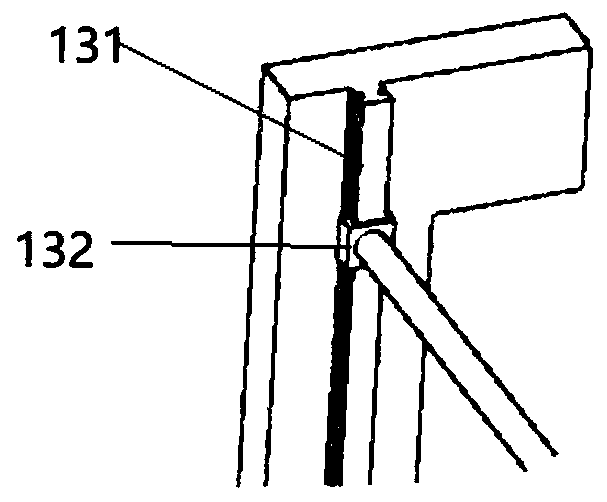

[0038] Such as figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, a continuous gathering feeding extrusion An integrated device, the mesh tension buffer device 1 is aligned with the winder, and is fixed on the ground one meter away from the winder, and the cutting device 2 is aligned with the mesh tension buffer device 1, and the distance from the mesh The material tension buffering device 1 is fixed on the ground for one meter, the tension stabilizing device 3 is aligned with the cutting device 2, and is fixed on the ground without interval, and the three gathering devices 4 are side by side close to the tension stabilizing device 3 The outlet end is fixed on the ground, the conveying device 5 and the gathering device 4 are vertically fixed on the ground, the discharge end of the conveying device 5 is aligned and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com