Handle type supporting leg vertical type trolley

A technology of leg stand and trolley, which is applied in the field of stand trolley, and can solve problems such as labor-intensive, construction space occupation, laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

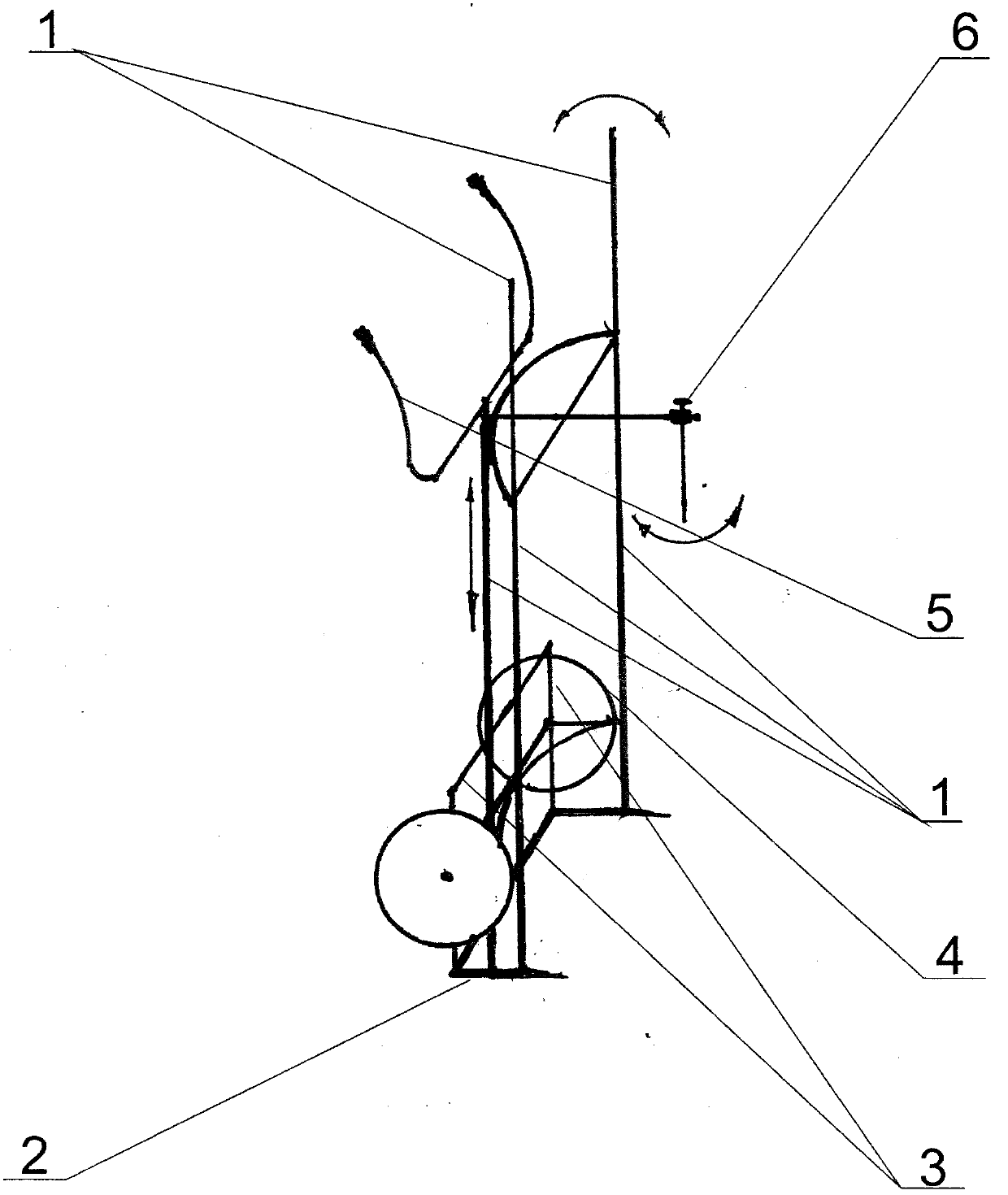

[0008] The invention is further explained below in conjunction with the drawings

[0009] In the figure, the main frame 1 is an open frame, and the concave fork 2 at the lower front end is provided with baffle slides. The double frame 3 is a one-port frame with wheels 4 in the middle, and the front end is hinged on The front lower end of the main frame 1; the central axis of the handlebar 5 is inserted into the sleeve under the main frame and fixed with elastic screws; the upper part of the rotating pickpocket 6 is a D-shaped spiral sleeve rod and the lower end is sleeved and fixed in On the central axis of the handlebar 5, vertical installation and vertical placement are carried out by rotating the adjusting crossbar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com