A device for reducing acid leaching and lead mud

A technology of leaching lead and acid, applied in the direction of lead-acid battery electrodes, etc., can solve the problem of not being able to reduce plate coating, etc., and achieve the effect of simple structure, convenient operation, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

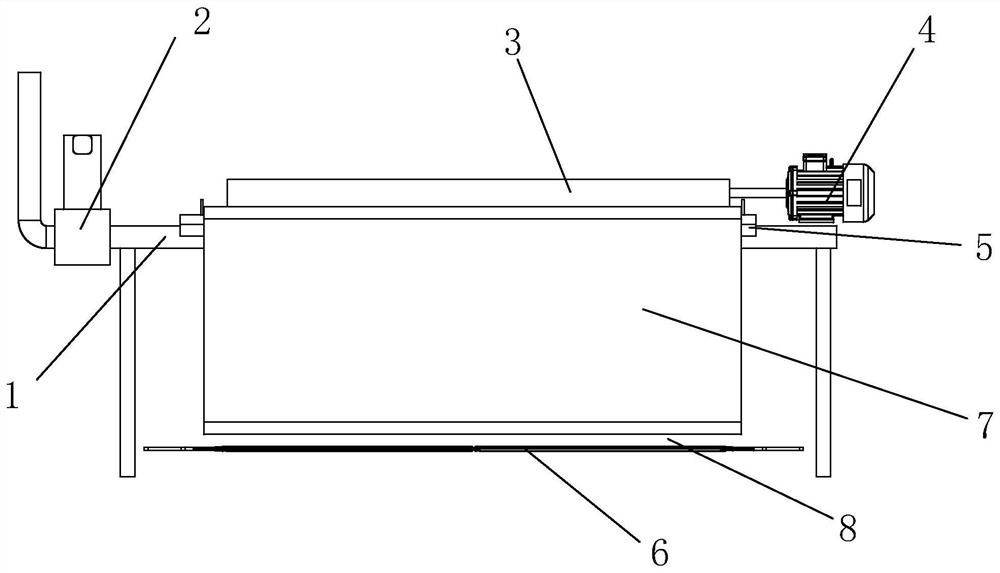

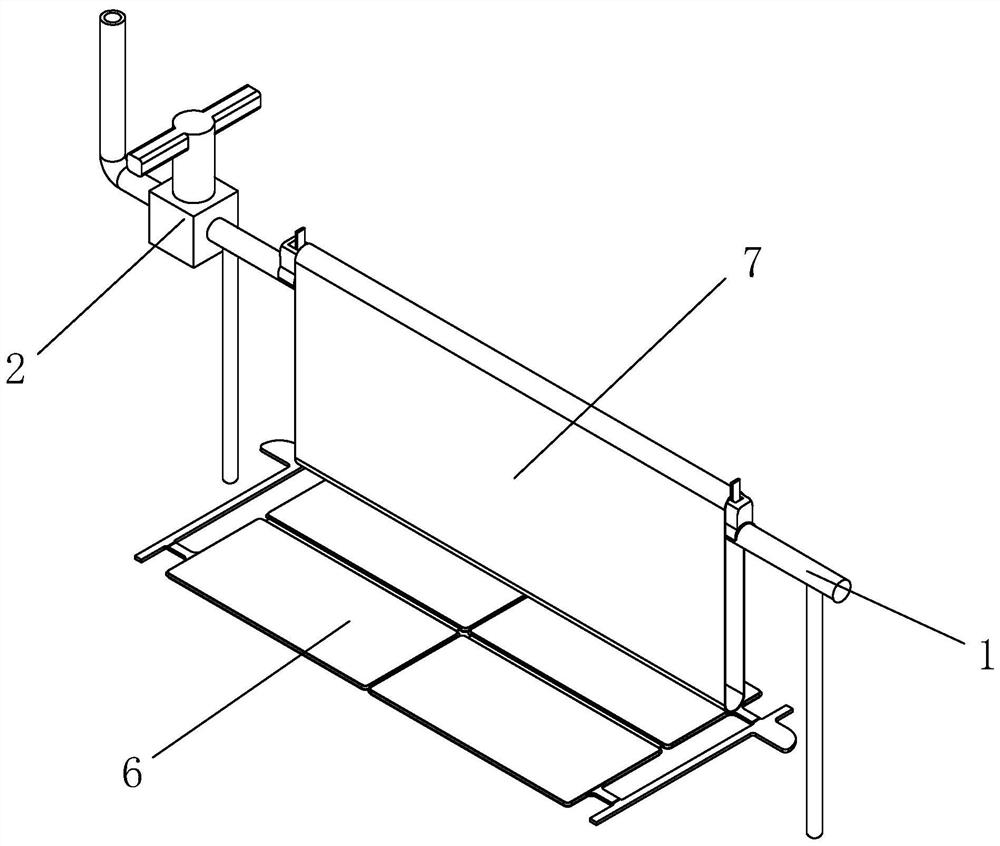

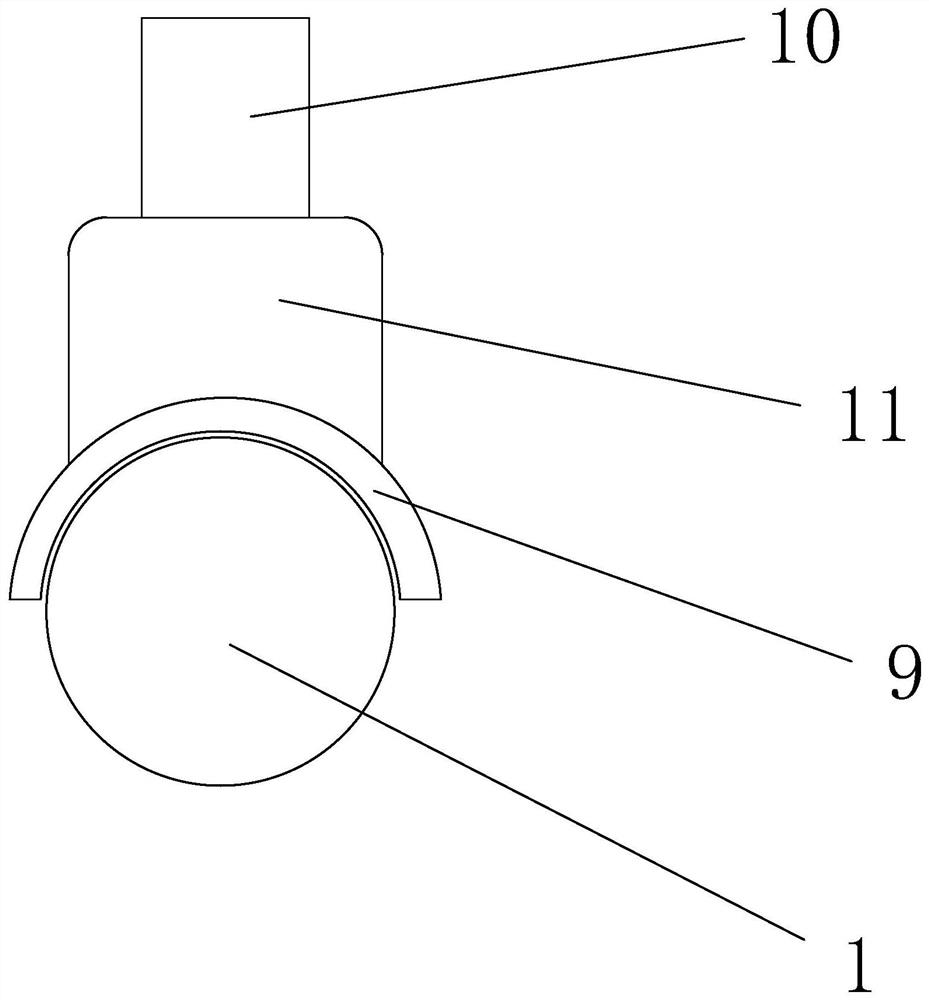

[0025] like figure 1 , 2As shown in , 4, a device for reducing acid leaching lead mud comprises polar plate 6, acid leaching cloth 7 connected end to end and open at both ends and acid leaching pipe 1 filled with sulfuric acid solution inside, and acid leaching cloth 7 is installed in the acid leaching cloth 7. On the pipe 1, the acid-spraying cloth 7 is made of acid-resistant polyester staple fibers. The acid-spraying cloth 7 is a multi-layer fine-grained non-woven fabric. The surface of the cloth is a mesh structure. The acid leaching used is filtered again, the length of the acid leaching cloth 7 is slightly larger than the length of the plate 6, which can ensure that every position on the surface of the electrode plate 6 can be leached with acid, and the lower part of the acid leaching cloth 7 is parallel to the plate surface of the electrode plate 6 and keeps A certain distance can ensure that each position of the electrode plate 6 is evenly sprayed with acid. The inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com