Quick-acting marinating food production equipment

A production equipment and food technology, which is applied in the field of quick-acting stewed food production equipment, can solve the problems of low stewed efficiency and inability to stew food, and achieve the effect of increasing the speed and efficiency of stewed food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

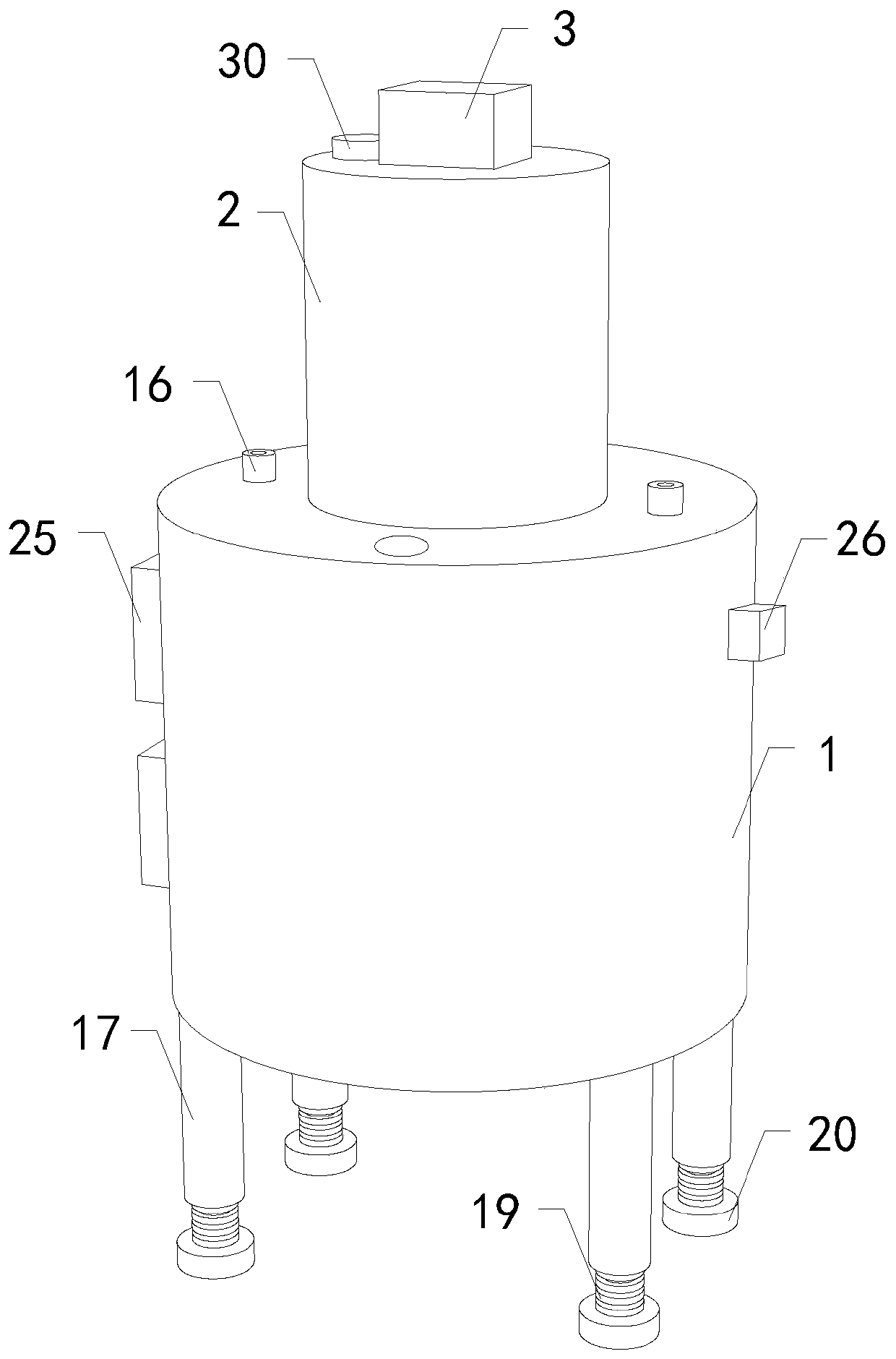

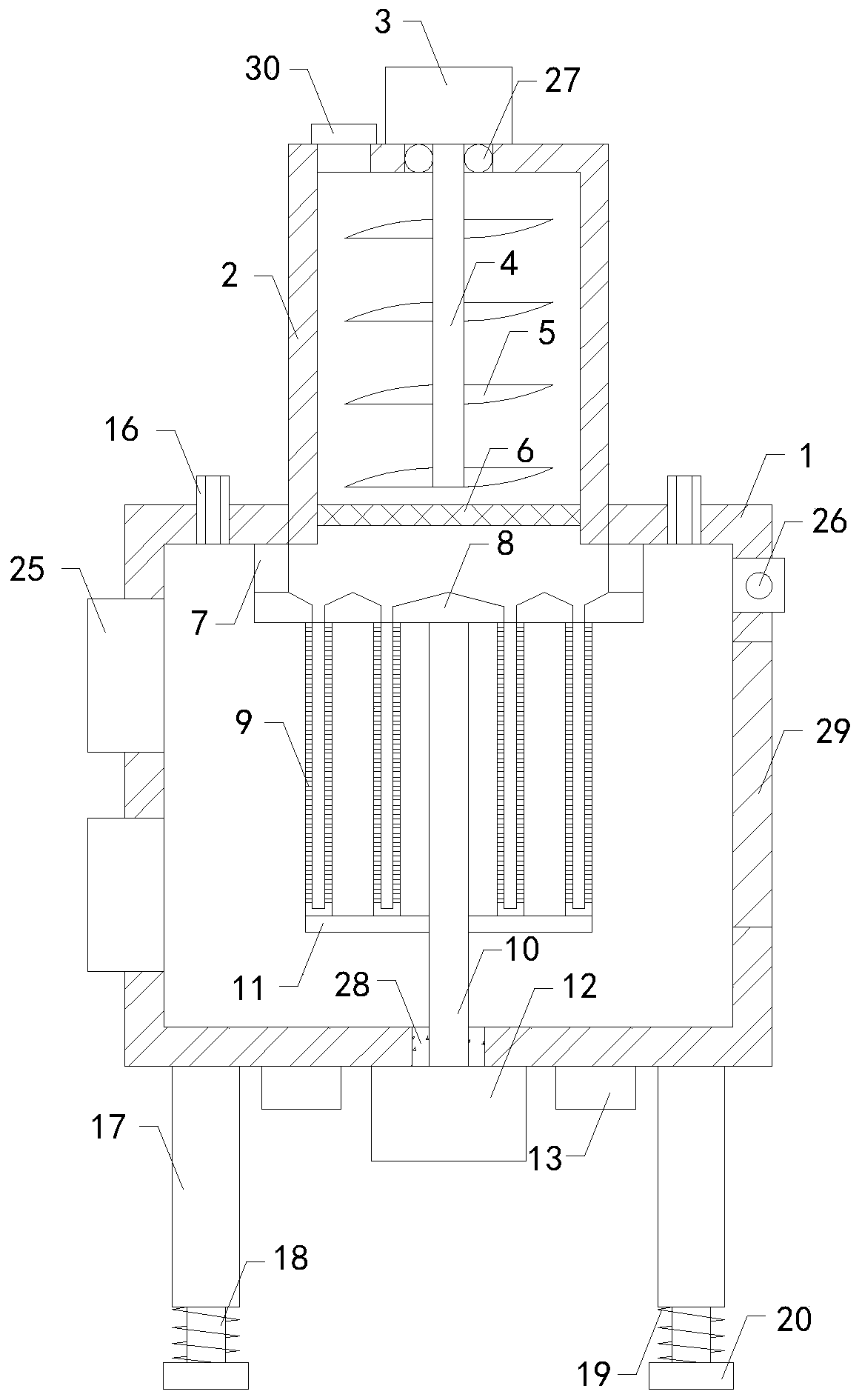

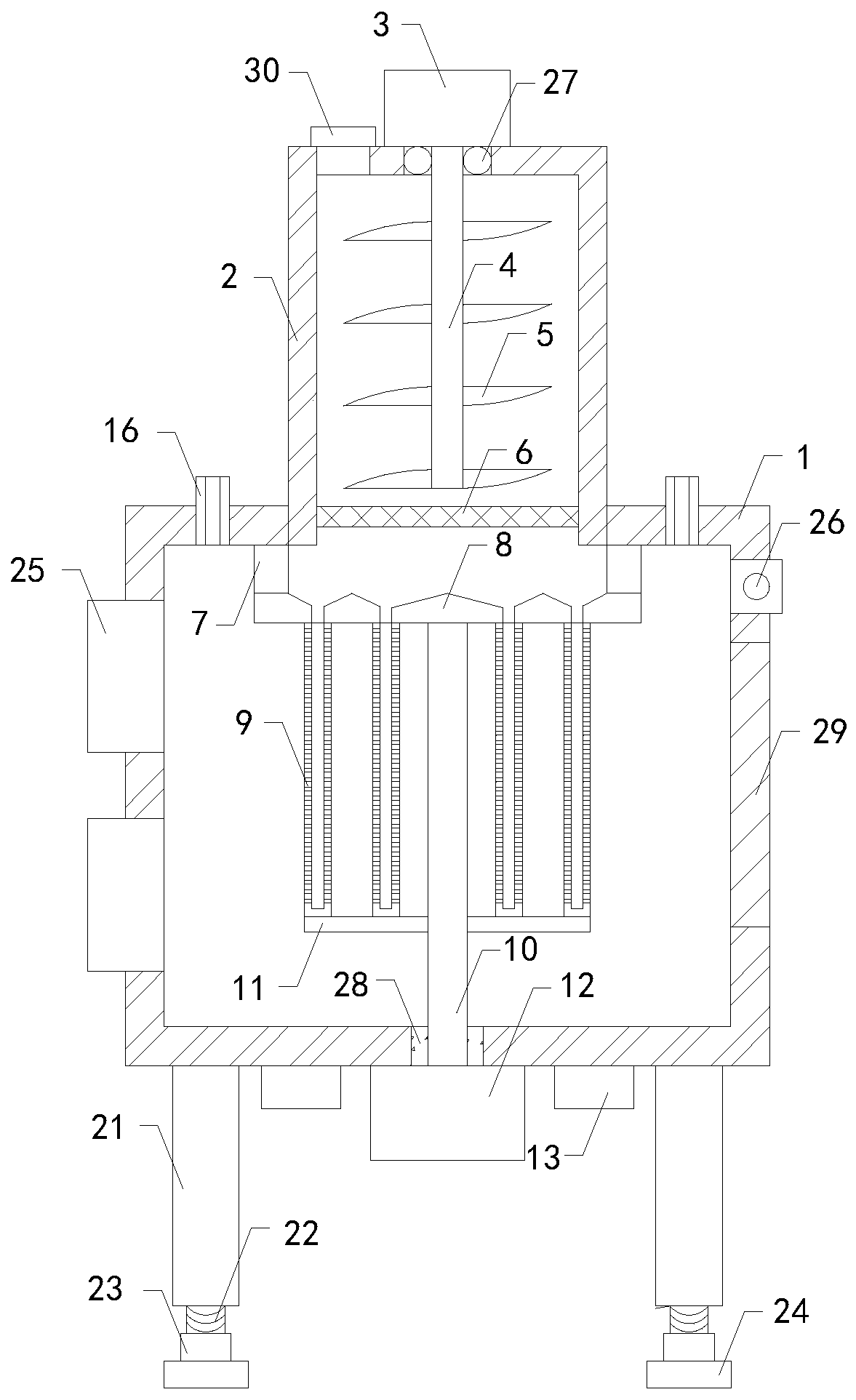

[0027] see Figure 1-2 , Figure 4-5, a quick-acting marinated food production equipment of the present invention, comprising a marinated box 1, a support device, a crushed material box 2, a crushed material motor 3, a crushed material shaft 4, multiple groups of crushed material blades 5, a filter net 6, and a connecting sleeve 7. Feeding tray 8, multiple sets of storage barrels 9, rotating shaft 10, fixed plate 11, halogen material motor 12 and two sets of heating devices 13, the interior of the halogenation box 1 is provided with a halogenation cavity, and the top of the halogenation box 1 is The side is connected with a feed port, the top cover of the feed port is equipped with a feed cover plate 14, the top front side of the marinating box 1 is connected with a water inlet, and the top cover of the water inlet is equipped with a water filling cover plate 15, and the marinating box 1 The left and right sides of the top of the top are respectively connected with two groups...

Embodiment 2

[0029] see figure 1 , Figure 3-5 , a quick-acting marinated food production equipment of the present invention, comprising a marinated box 1, a support device, a crushed material box 2, a crushed material motor 3, a crushed material shaft 4, multiple groups of crushed material blades 5, a filter net 6, and a connecting sleeve 7. Feeding tray 8, multiple sets of storage barrels 9, rotating shaft 10, fixed plate 11, halogen material motor 12 and two sets of heating devices 13, the interior of the halogenation box 1 is provided with a halogenation cavity, and the top of the halogenation box 1 is The side is connected with a feed port, the top cover of the feed port is equipped with a feed cover plate 14, the top front side of the marinating box 1 is connected with a water inlet, and the top cover of the water inlet is equipped with a water filling cover plate 15, and the marinating box 1 The left and right sides of the top of the top are respectively connected with two groups o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com