Full-dynamic seat back synchronous linkage device

A synchronous linkage, full dynamic technology, applied to other seating furniture, chairs with vertically adjustable seats, stools, etc., can solve the problems of complex installation, insufficient versatility, and difficulty in mass production, and achieve convenient assembly, Overall strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

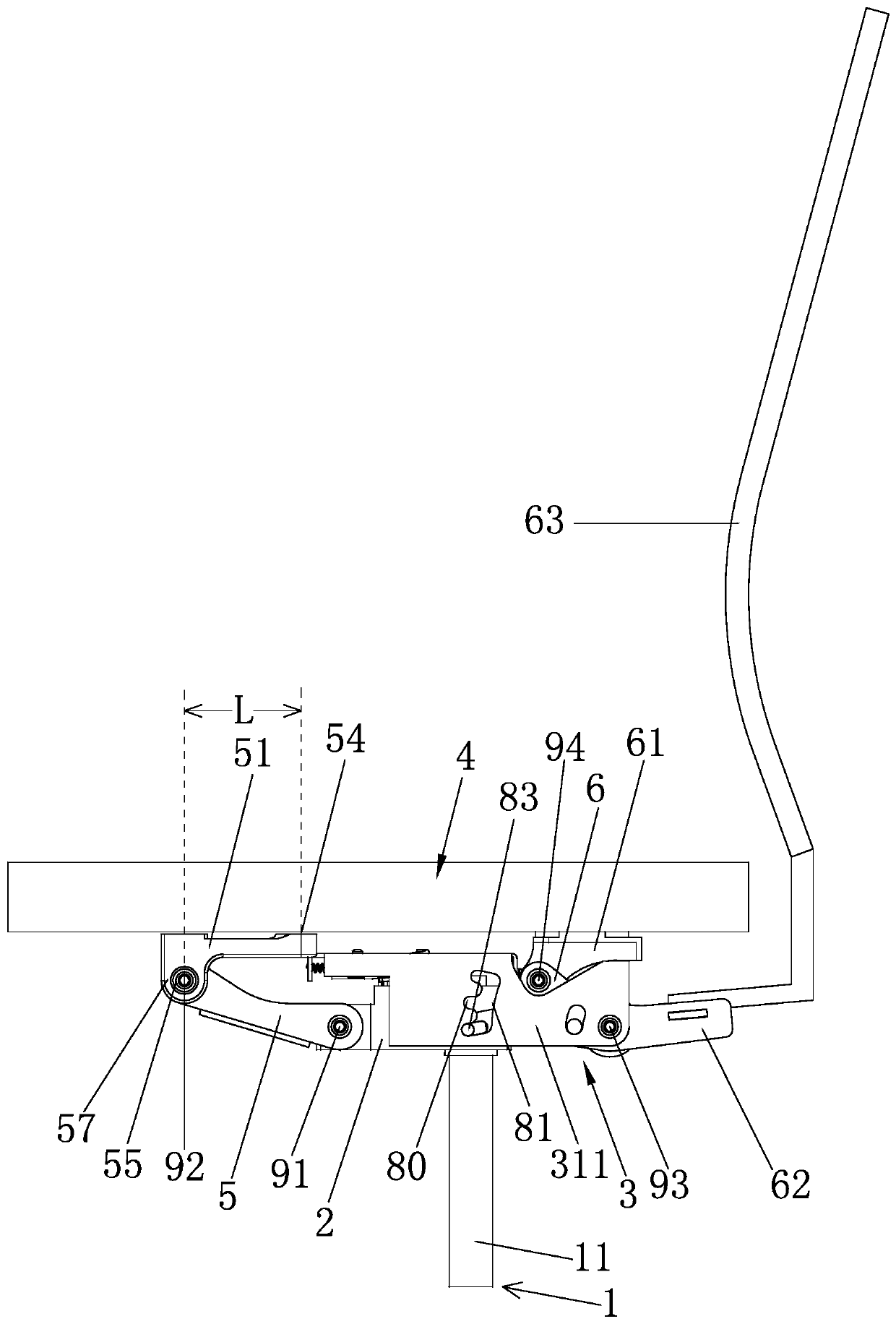

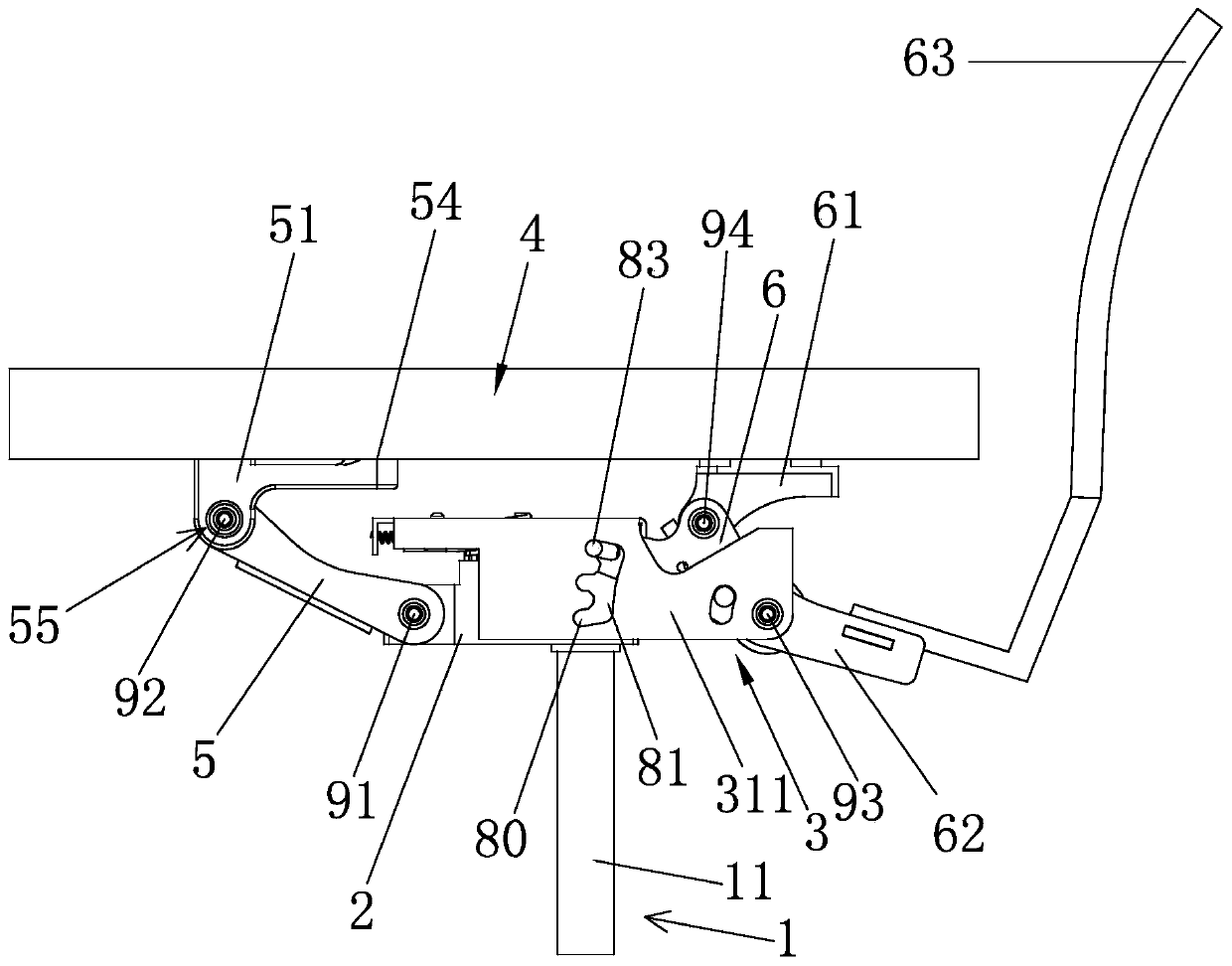

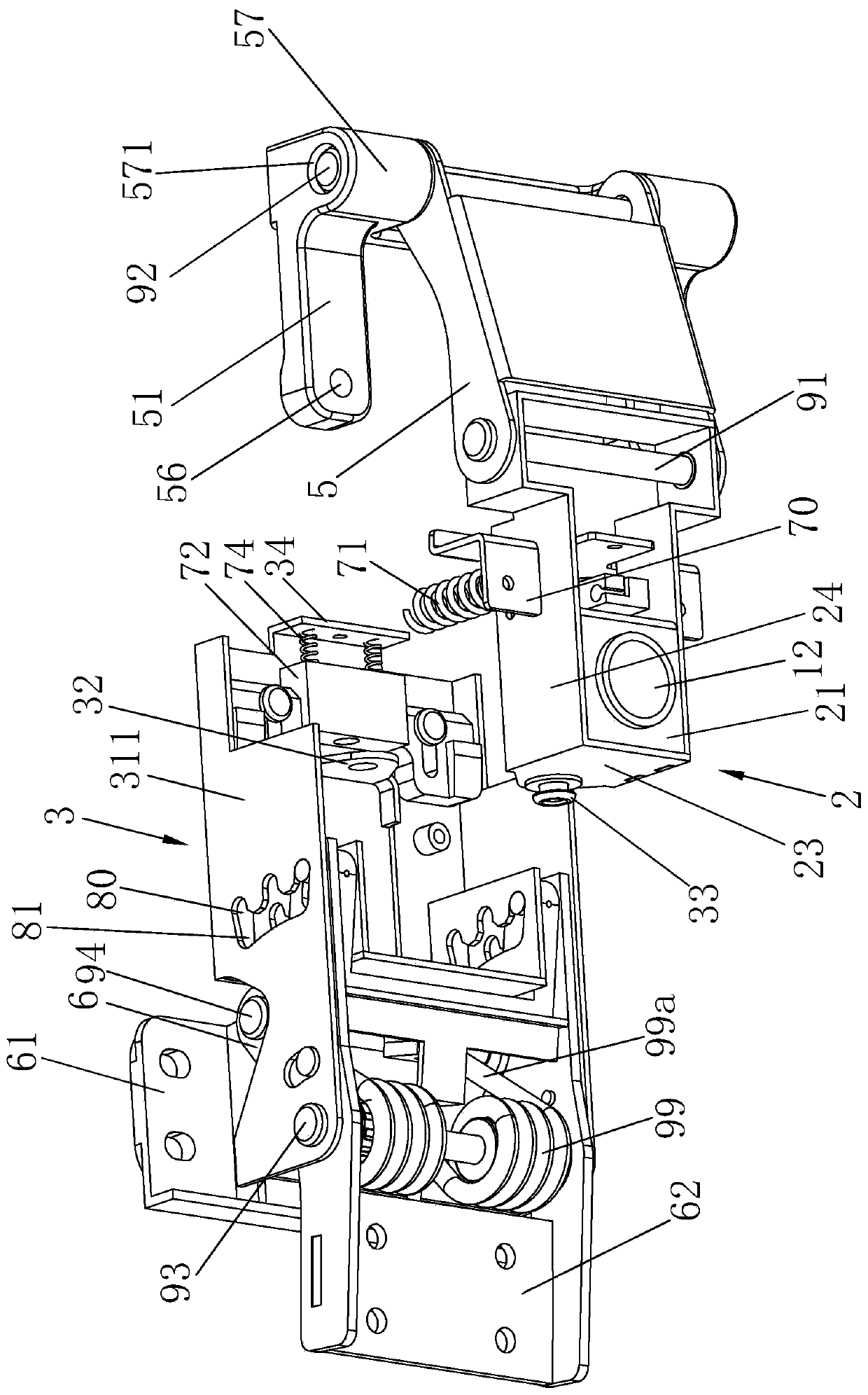

[0064] Embodiment 1: The full dynamic seat back synchronous linkage device of the present invention is an integral part of the seat, and the whole seat is described in detail next, so that the present invention and its application can be understood more clearly and appropriately; as Figure 1-18 As shown, the seat includes:

[0065] The first base 2 configured to connect the seat support assembly 1, the first base 2 includes a bottom plate 21 and a front plate 22 and a rear plate 23 extending upward from the front and rear ends of the bottom plate 21, the front plate 22 , The rear plate 23 plays a supporting role; the seat support assembly 1 includes a support rod 11 and a support foot (not shown), and a socket 12 is correspondingly provided on the bottom plate 21, and the support rod 11 is arranged in the socket 12 , the support rod 11 and the support feet are standing on the ground, so the first base 2 is kept horizontal and fixed relative to the ground except that it rotate...

Embodiment 2

[0087] Embodiment 2: The difference with Embodiment 1 is that, as Figure 19 As shown, the two elastic connectors 51 in this embodiment are independent components, which is designed to facilitate layout, and on the basis of meeting the requirements, it saves materials and reduces costs.

Embodiment 3

[0088] Embodiment 3: The difference from Embodiment 1 is that the second base 3 rotates around the first base 2 through the rotating shaft 33, the rotating shaft 33 is a whole long axis, and the swing reset mechanism in this embodiment is sleeved The torsion spring (not shown) on the above-mentioned rotating shaft 33 has two torsion springs, one torsion arm of the torsion spring is connected to the base, and the other torsion arm of the torsion spring is connected to the left or right side of the top plate 31; it is realized by the torsion spring The rotation of the second base 3 resets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com