Grinding mechanism, grinding machine and grinding method

A grinding mechanism and grinding machine technology, applied in the grinding field, can solve the problems of reducing manufacturing costs, assembly errors affecting the size of the thickness, disadvantages, etc., and achieve the effects of reducing manufacturing costs, all-round cleaning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

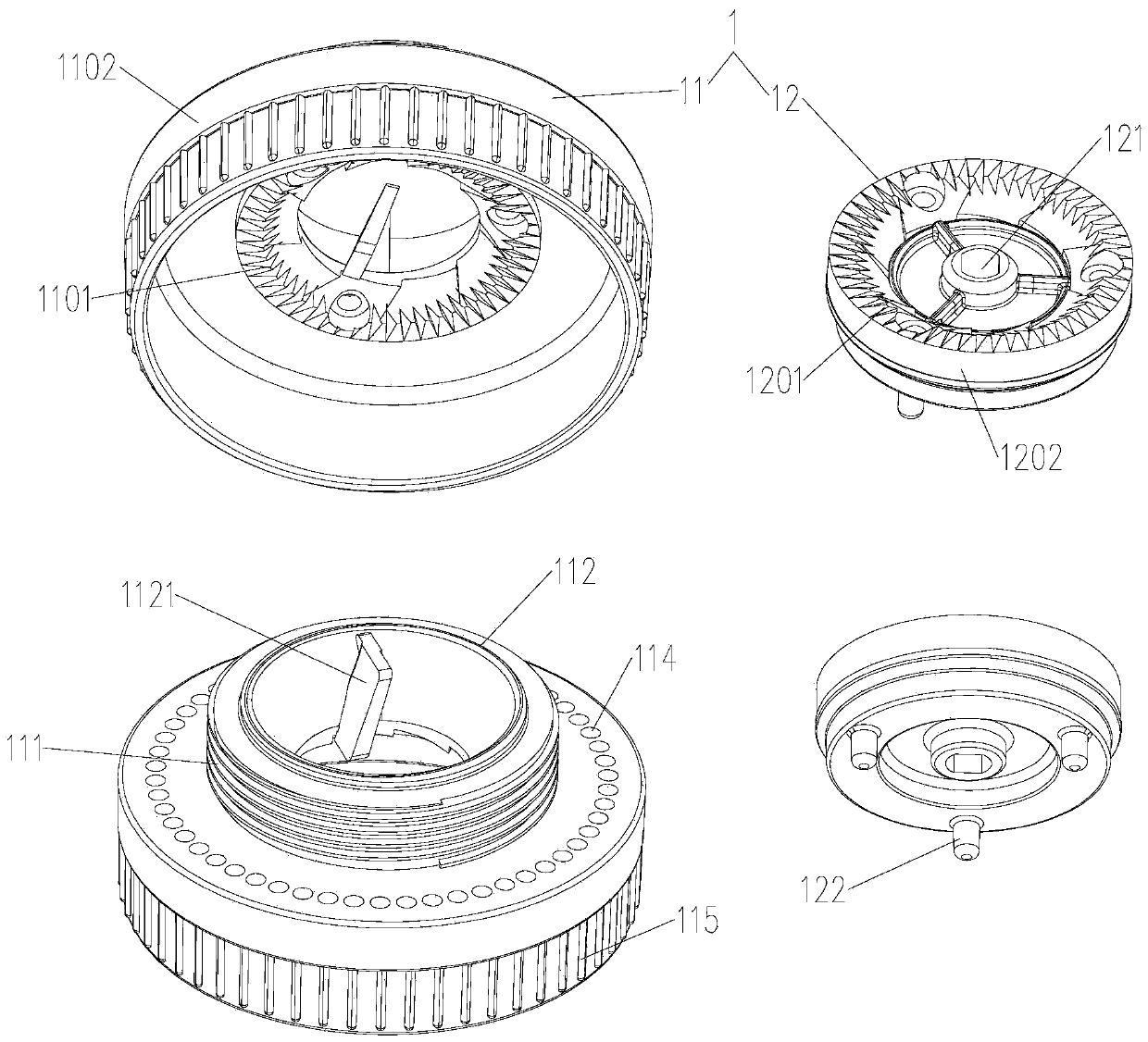

[0107] A grinding mechanism 1, such as figure 1 As shown, an upper grinding disc assembly 11 and a lower grinding disc assembly 12 are included, which are arranged independently.

[0108] Wherein, the upper grinding disc assembly 11 is provided with a connecting part that can be detachably connected to the outside, and the exterior may be a specific bracket 28 or a shell, and also other parts that can fix the upper grinding disc assembly 11.

[0109] The lower grinding disc assembly 12 receives an external drive to rotate and can be independently detached. The external drive can be manual drive or electric drive, for example, it can be rotated by hand, or it can be driven by a motor connection.

[0110] It can be seen from the above structure that both the upper grinding disc assembly 11 and the lower grinding disc assembly 12 can be disassembled separately for thorough cleaning, which can prevent the coffee powder from accumulating on the upper grinding disc assembly 11 and / or the lo...

Embodiment 2

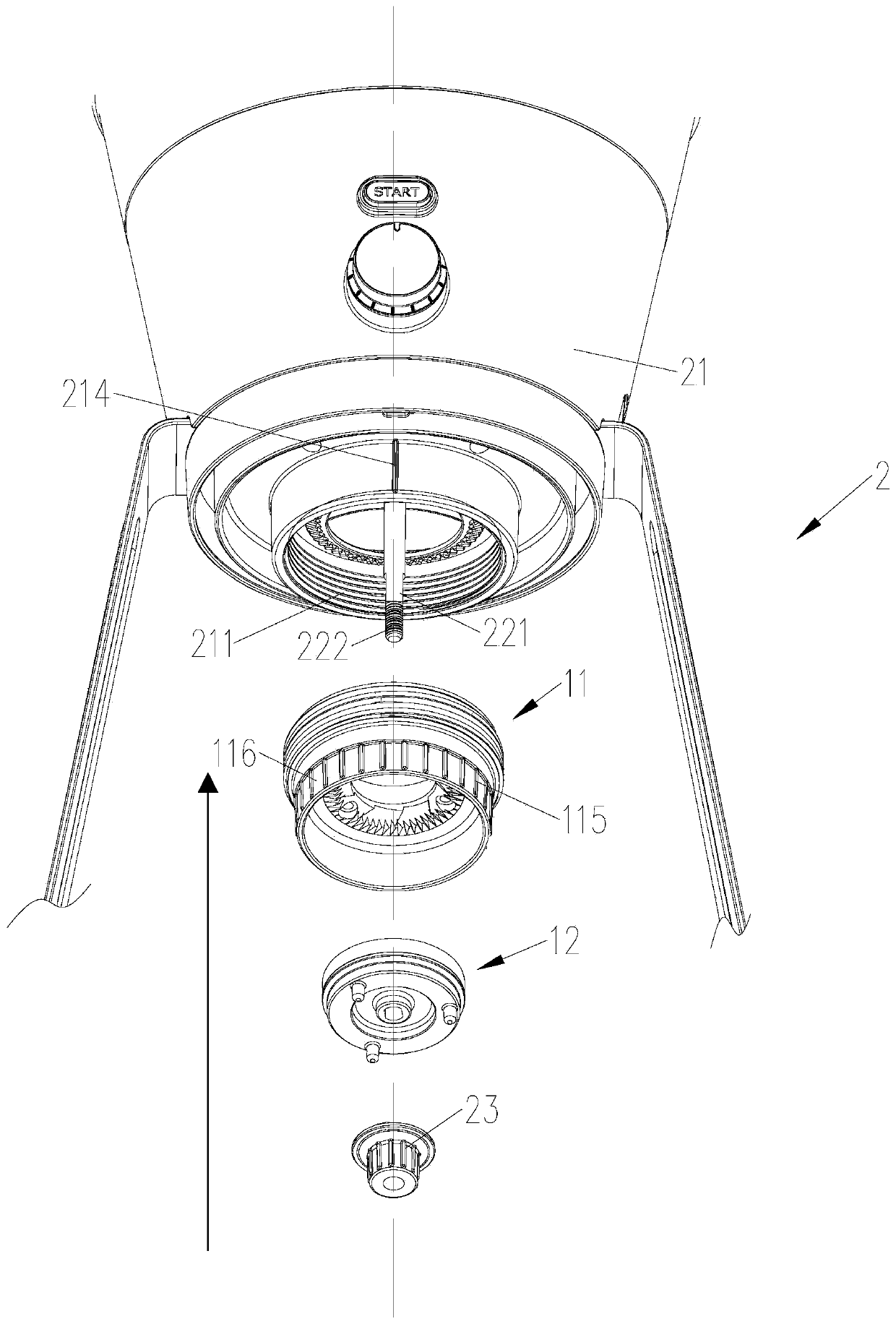

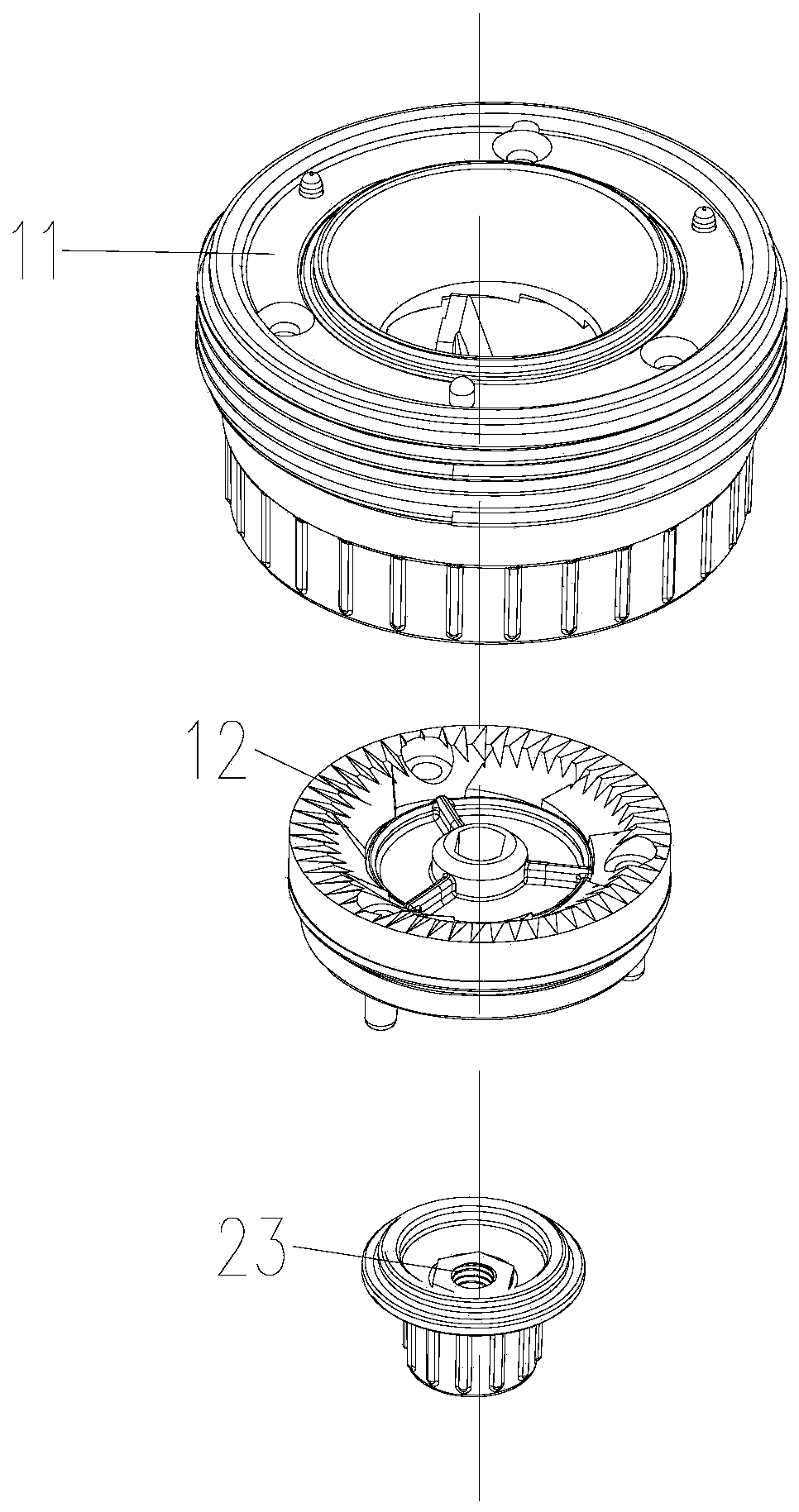

[0118] This embodiment discloses a grinder 2, which has the advantages of stably adjusting the thickness of coffee powder, being able to clean thoroughly, and having a simple structure, such as Figure 1 to 12 As shown, it includes a host 21, a driving mechanism 22, and the grinding mechanism 1 of the first embodiment.

[0119] Such as figure 2 , The upper grinding disc assembly 11 is detachably connected to the host 21 through the connecting portion, and the upper grinding disc assembly 11 can move upward along its axial direction to a state of extreme tight fit with the host 21. The lower grinding disc assembly 12 can be detachably connected with the driving mechanism 22 and rotates with the driving mechanism 22. When the lower grinding disc assembly 12 is connected in place and the upper grinding disc assembly 11 and the host 21 are in a tightly matched state, the grinding gap is the maximum.

[0120] To make the ground coffee powder finer, you only need to adjust the upper gri...

Embodiment 3

[0171] This embodiment discloses another grinding machine 2, which is different from the grinding machine 2 of embodiment 2 in:

[0172] In this embodiment, the upper grinding disc assembly 11 is provided with a plurality of retractable first mandrels 113, and the main body 21 is provided with a plurality of first recesses 212; the upper grinding disc assembly 11 is connected with the main body 21 to enable the grinding When the gap reaches the set requirement, each first mandrel 113 and each first recessed portion 212 respectively cooperate to limit and fix the upper grinding disc assembly 11 and prevent the upper grinding disc assembly 11 from rotating. Such as Figure 13 with Figure 14 As shown, the upper grinding disc assembly 11 is provided with a blind hole for the first mandrel 113 to be installed and extended. After adjusting the position of the upper grinding disc assembly 11, the first top rod 113 extends into the first recess 212, so that the upper grinding disc assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com