Automatic cleaning type underground engineering construction sewage discharge device

An underground engineering and automatic cleaning technology, applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve problems such as easy blockage of sewage pipes, achieve convenient recycling, realize dry and wet separation, and improve discharge efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

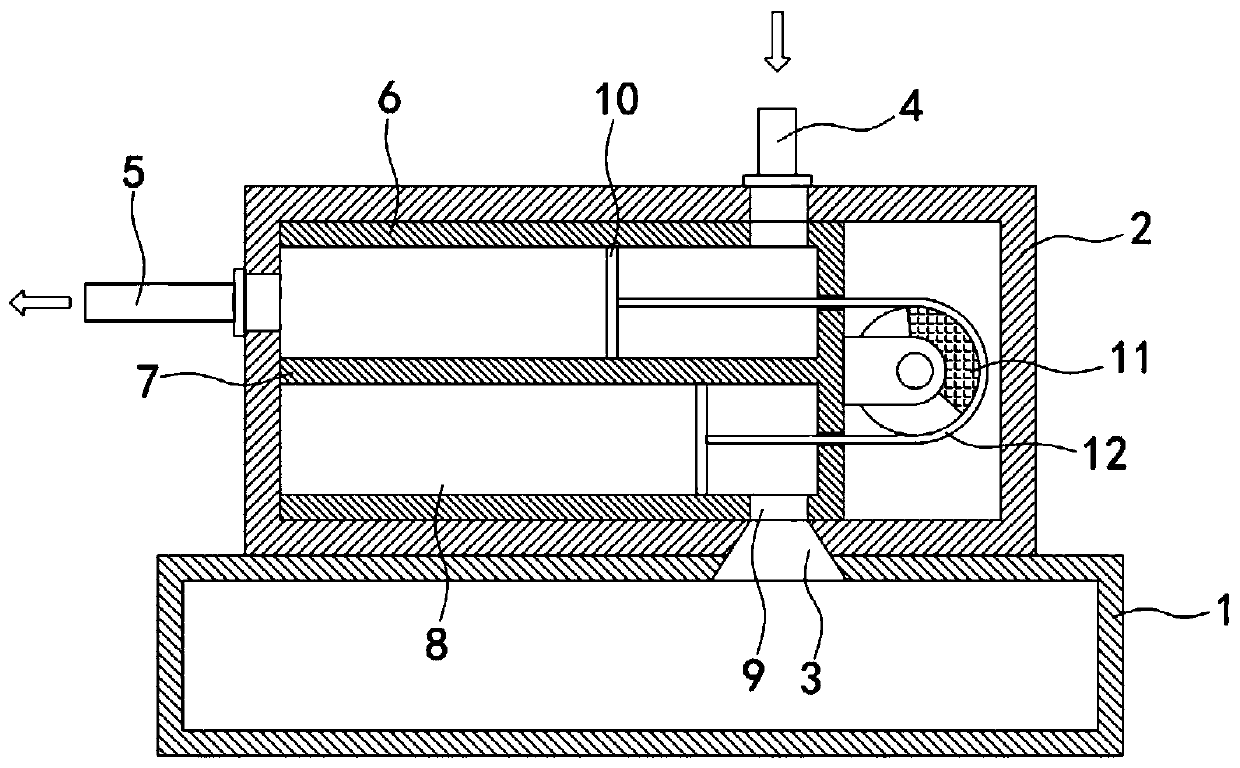

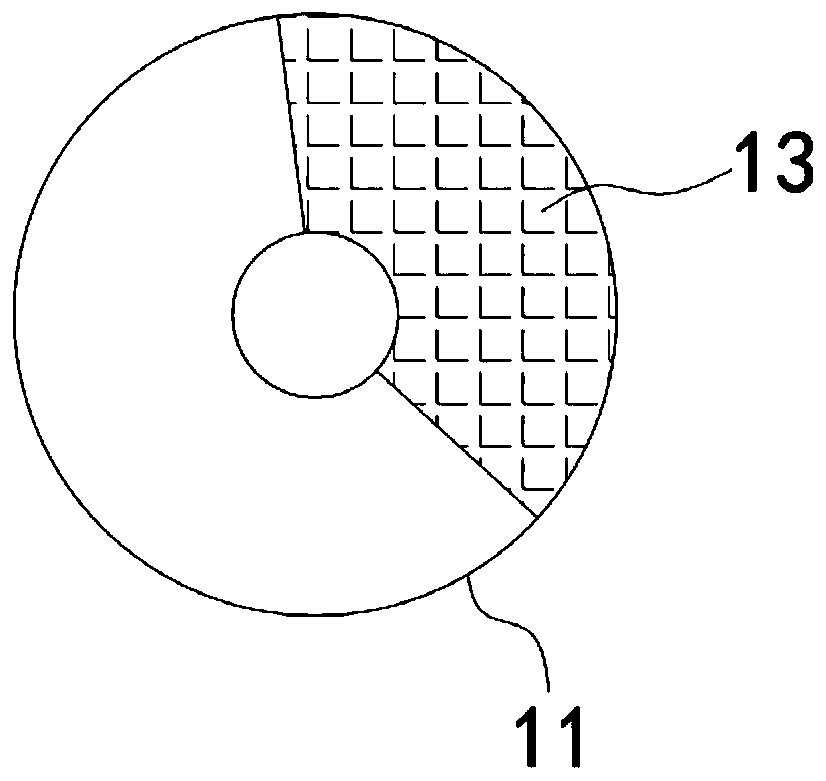

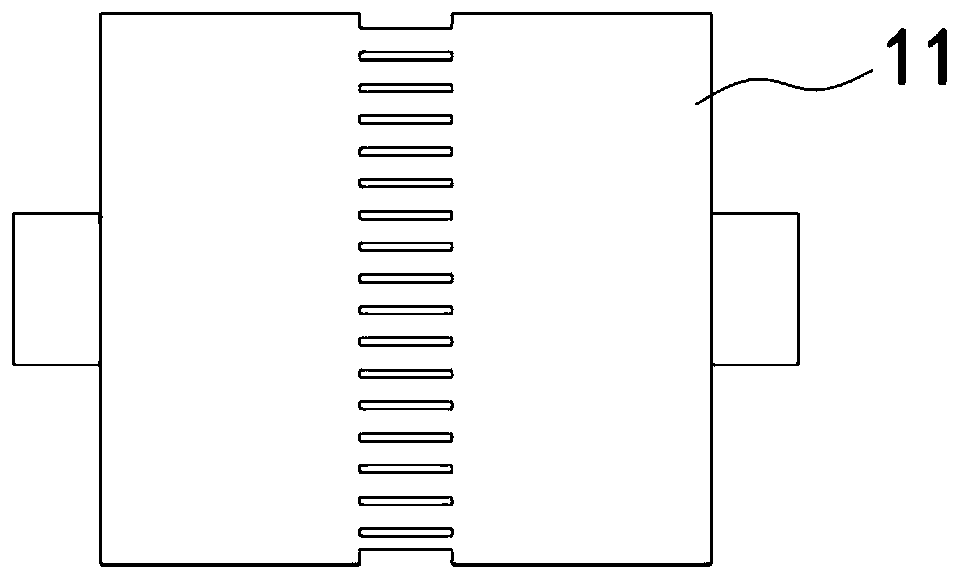

[0023] Such as Figure 1-4 As shown, an automatic cleaning type sewage discharge device for underground engineering construction includes a storage box 1 and a cylindrical collection box 2. The storage box 1 and the collection box 2 are connected through the sewage outlet 3. The sewage outlet 3 includes a 2. The upper opening at the bottom and the lower opening provided on the upper end of the storage box 1, the upper opening and the lower opening correspond to each other and communicate with each other, and the upper and lower openings together form a tapered opening with a small top and a large bottom, which is conducive to the rapid discharge and collection of impurities. The upper end of the box 2 is provided with a water inlet pipe 4, and a drain pipe 5 is provided on the side wall. The inner container 2 is rotationally sealed and connected with an inner container 6 with an open end. The inner container 6 is fixedly connected with a partition 7 along its axial direction. ...

Embodiment 2

[0028] Such as Figure 5 As shown, the difference between the present embodiment and Embodiment 1 is that: the storage box 1 is fixedly connected with a water filter plate 14 provided with an inclination; The part of the box 1 located at the lower side of the filter plate 14 is fixedly communicated.

[0029] In this embodiment, by setting the water filter plate 14, the dry-wet separation of impurities can be realized, which facilitates the recovery and treatment of impurities in the later stage, and, because the return pipe 15 is provided, the fluid in the drain pipe 5 flows rapidly, according to Bernoulli's principle It can be seen that the pressure in the drain pipe 5 is lower than the pressure of the return pipe 15, and under the action of the pressure difference, the drain pipe 5 will suck the sewage in the return pipe 15 and take the sewage away, thereby reducing the subsequent sewage treatment process, and at the same time , the storage space of the storage box 1 can al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com