A stamping equipment for mechanical stamping parts

A technology for mechanical stamping and stamping equipment, applied in the field of stamping equipment, can solve the problems of high cost, difficult to popularize, complicated device structure, etc., and achieve the effects of low cost, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

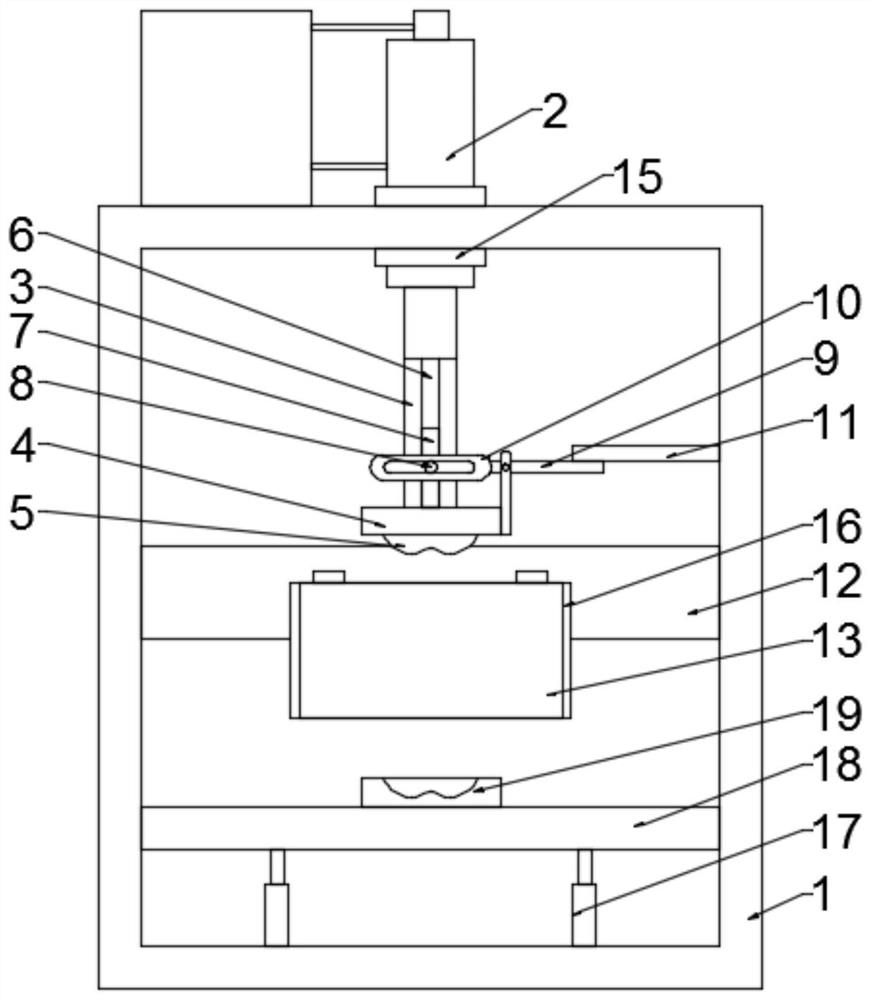

[0020] Example 1: Please refer to Figure 1-3 , a stamping equipment for mechanical stamping parts, including a frame 1, a hydraulic cylinder 2 is fixedly connected to the top of the frame 1, a connecting rod 3 is fixedly connected to the output end of the hydraulic cylinder 2, and the bottom of the connecting rod 3 is fixedly connected through a horizontal seat 4 There is stamping upper die 5;

[0021] When in use, the hydraulic cylinder 2 is turned on, and the plunger rod at the output end of the hydraulic cylinder 2 moves up and down to drive the connecting rod 3 to move up and down, thereby stamping the iron plate to be processed into the required shape, and automatically goes up after the stamping is completed;

[0022] The connecting rod 3 is made of non-ferromagnetic material, the middle part of the connecting rod 3 is provided with a chute 6, the inside of the chute 6 is slidably connected with a magnet 7, and the middle part of the front side of the magnet 7 is fixedl...

Embodiment 2

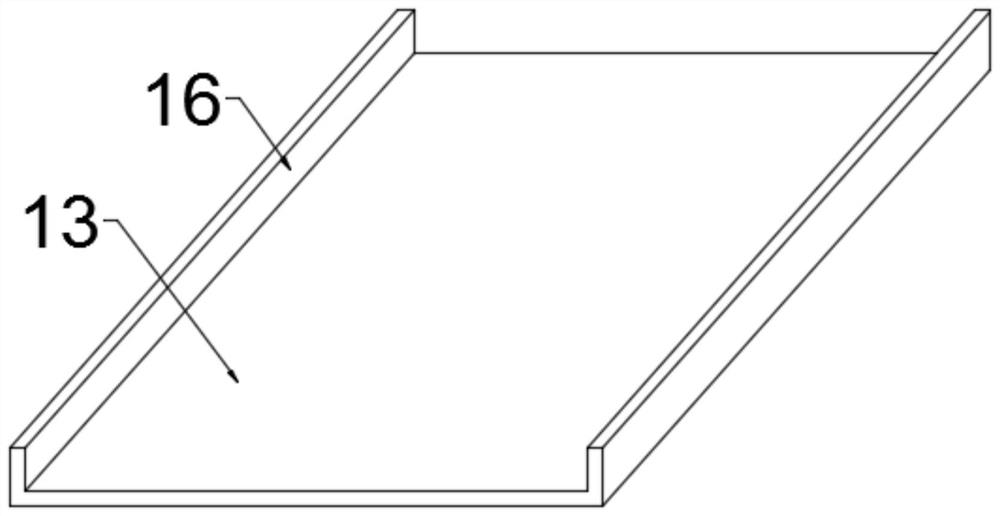

[0032] Embodiment 2: This embodiment is a further improvement of the previous embodiment: both sides of the material guide plate 13 are fixedly connected with material guide ribs 16 . The setting of the material guide rib 16 can prevent the stamping parts from falling sideways, and facilitate the collection of stamping parts.

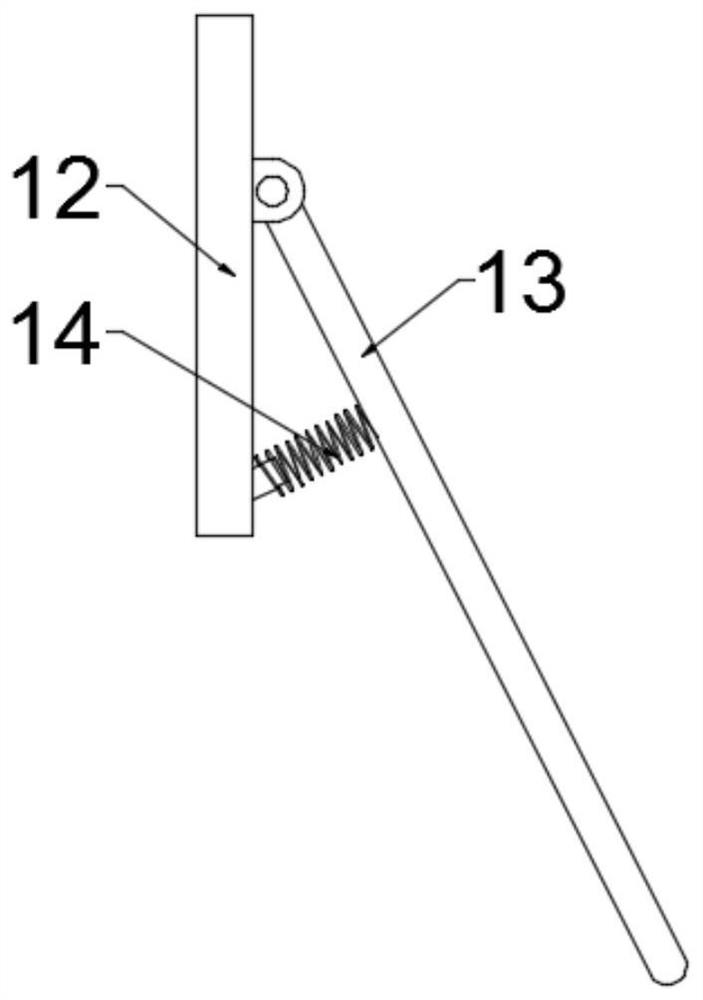

[0033] The working principle of the present invention is: when in use, the hydraulic cylinder 2 is opened, and the plunger rod at the output end of the hydraulic cylinder 2 moves up and down to drive the connecting rod 3 to move up and down, thereby punching the iron plate to be processed into a required shape, and automatically after the stamping is completed. Up, when going up, the magnet 7 will absorb the stamping parts and drive up synchronously, when the swing rod 9 intersects with the limit stop rod 11 when it goes up, the swing rod 9 will be in the position of the limit stop rod 11 when it continues to go up Rotating downward, the magnet 7 will g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com