Four-shaft mechanical arm

A robotic arm and shaft arm technology, applied in the field of robotics, can solve the problems of increased load, increased weight of the robotic arm, and low accuracy of the robotic arm, and achieves the effect of lowering the center of gravity, rational structure, and improving movement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Combine below Figure 1 to Figure 6 The present invention is further described.

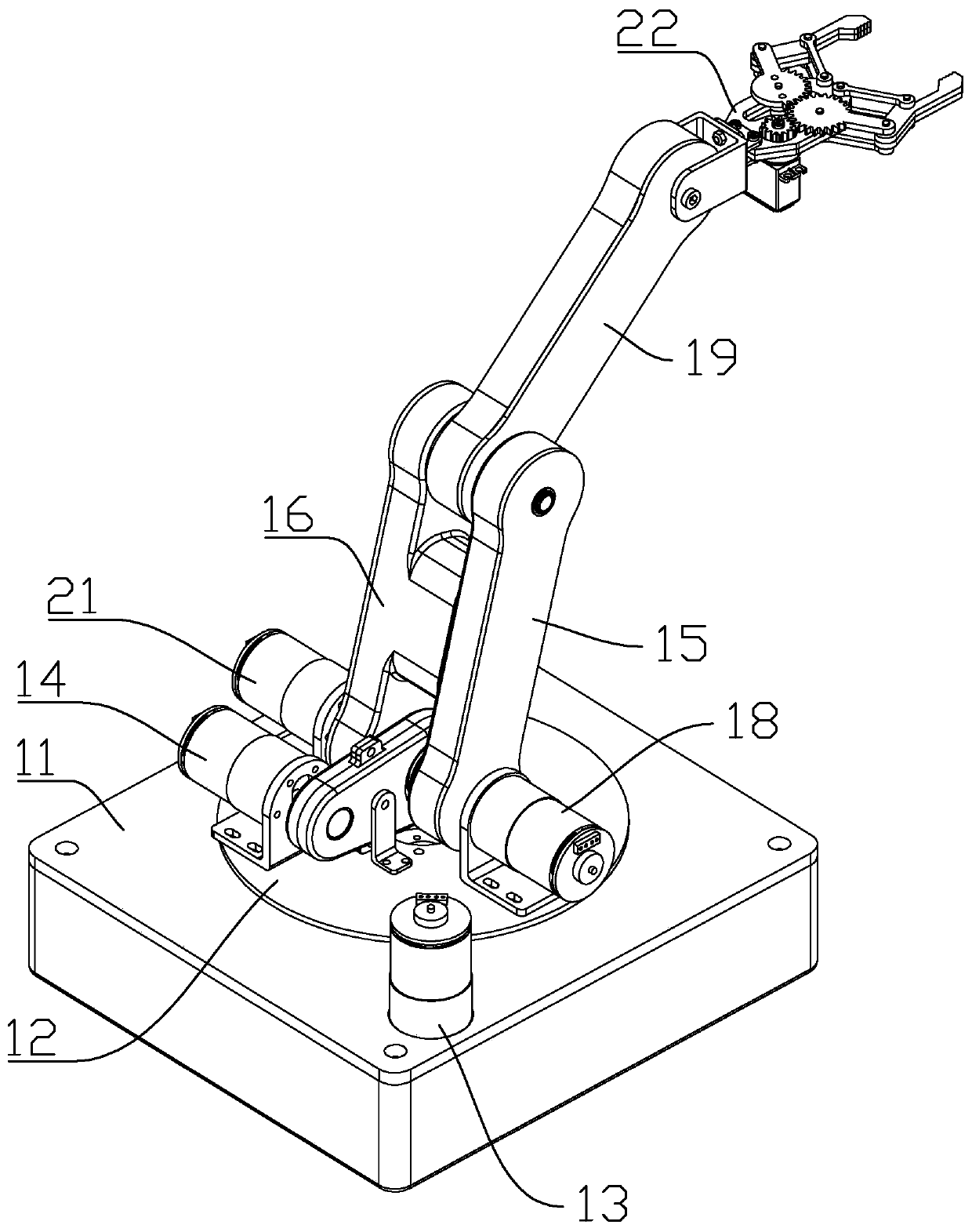

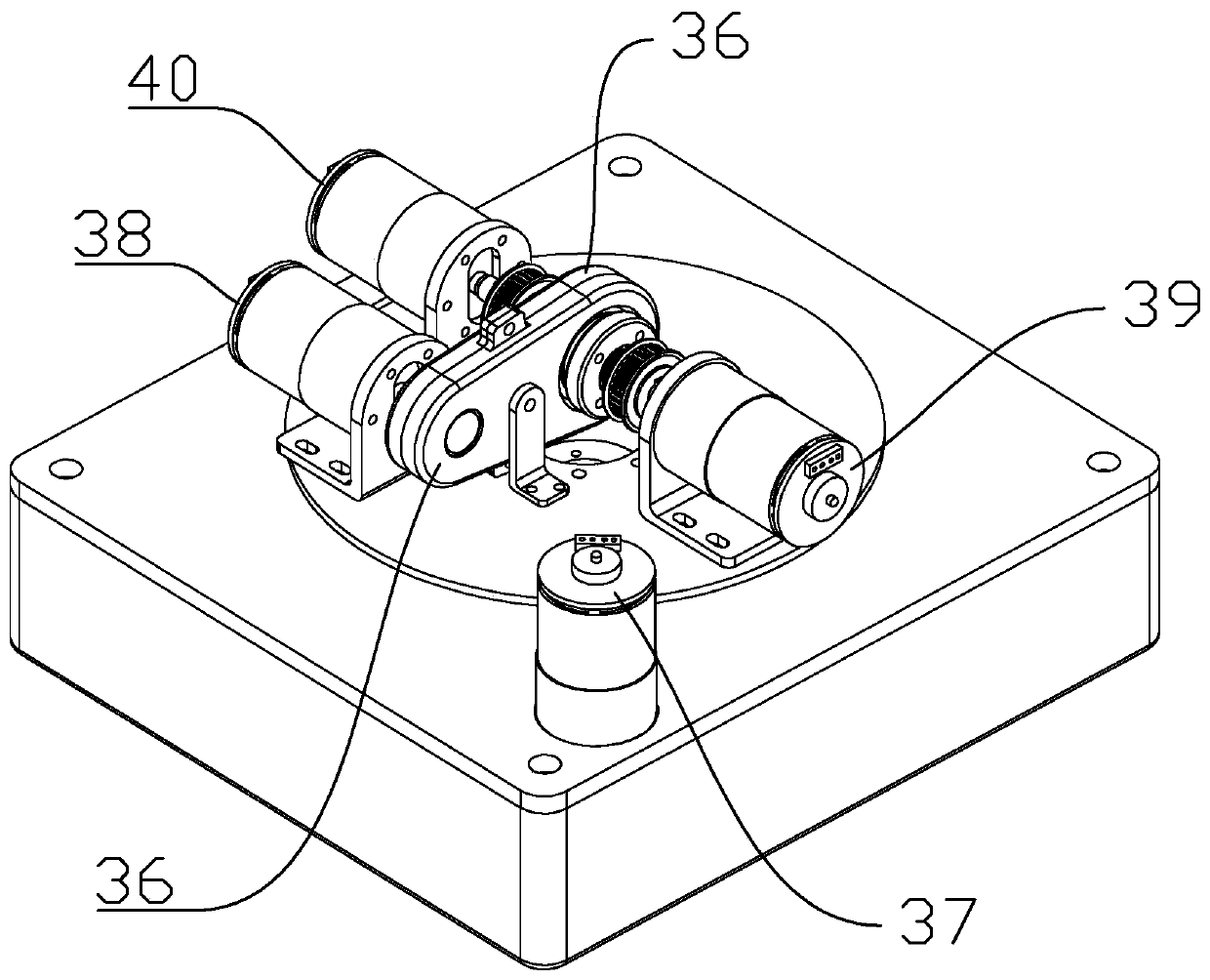

[0026] The present invention relates to a four-axis mechanical arm, which includes a base 11, a one-axis assembly, a two-axis assembly, a three-axis assembly and a four-axis assembly.

[0027] The one-axis assembly is installed on the base 11, and the one-axis assembly includes a one-axis turntable 12 and one-axis driver 13, and the one-axis driver 13 selects a motor, and the one-axis driver 13 drives the one-axis turntable 12 to rotate, and the one-axis driver 13 passes through a toothed belt or a flat The belt drives the one-axis turntable 12 .

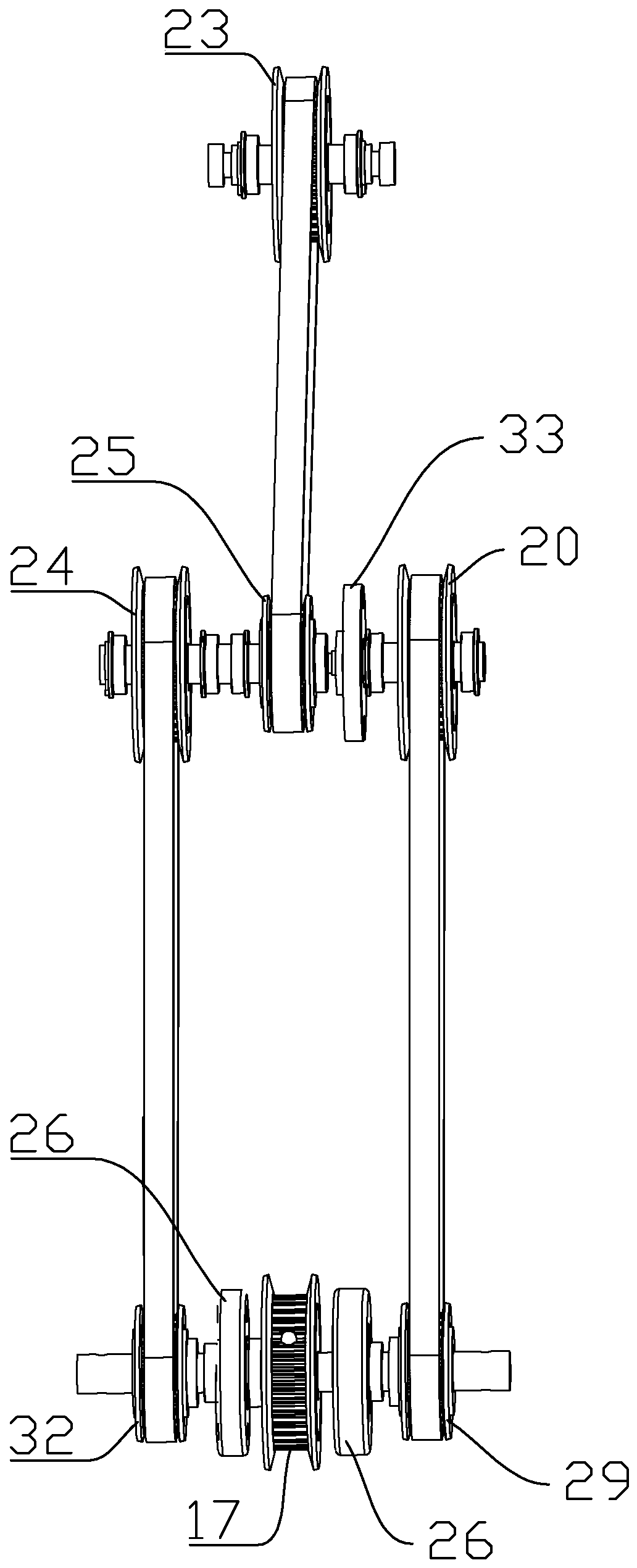

[0028] The two-axis assembly includes a two-axis driver 14, a two-axis one arm 15, a two-axis two arms 16 and a two-axis driven wheel 17. The two-axis driver 14 selects a motor, and the two-axis driver 14 is installed on the one-axis turntable 12. The two ends of two shafts and one arm 15 are respectively two and three input ends and two and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com