An agricultural rice harvesting equipment

A technology for collecting equipment and paddy, applied in the directions of loading/unloading, conveyor, transportation and packaging, etc., can solve the problems of dust raising, high degree of human harm, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

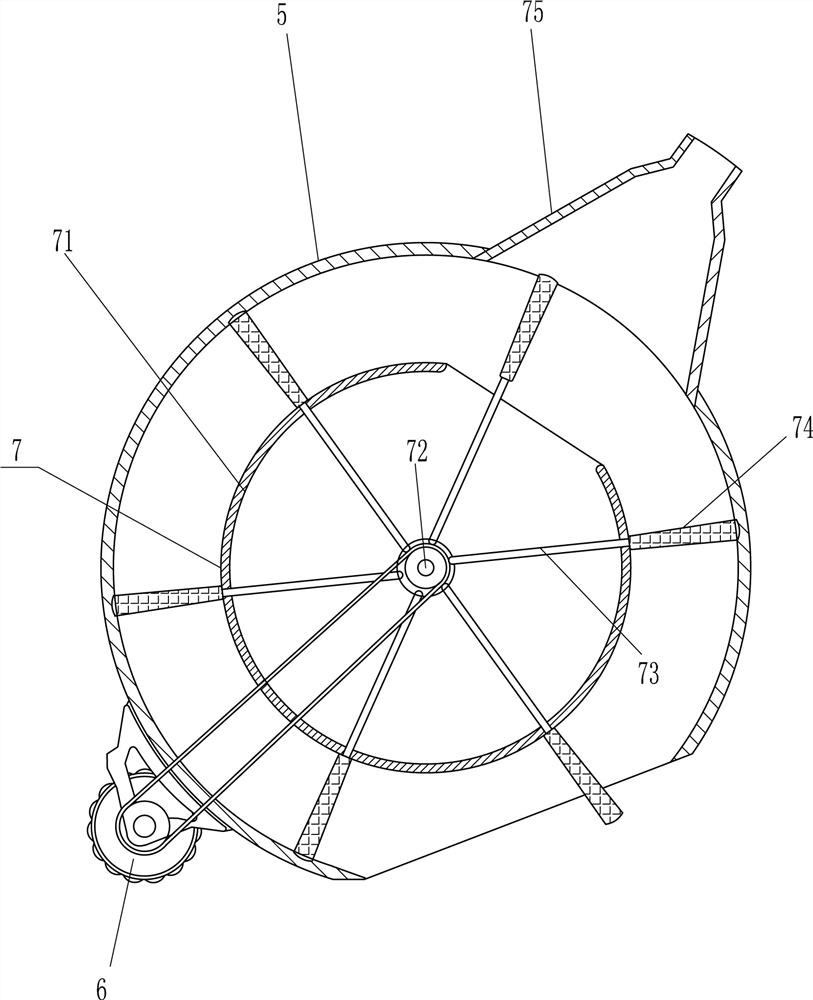

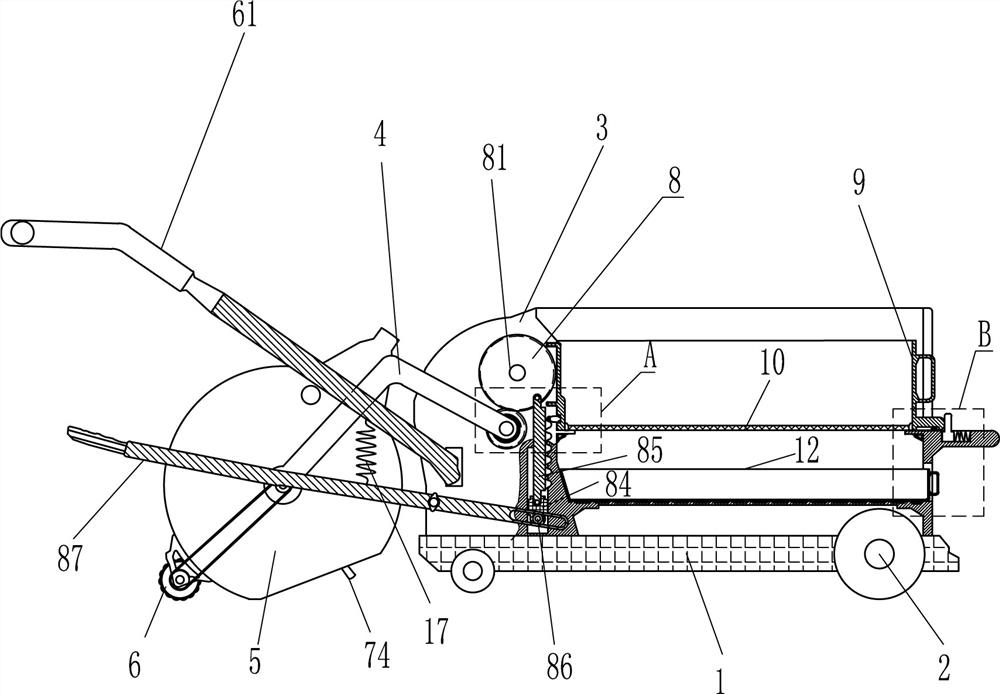

[0020] refer to figure 1 , a kind of agricultural rice post-sun collection equipment, including a bottom frame 1, a first roller 2 and an installation frame 3, the bottom of the bottom frame 1 is provided with the first roller 2 in a rotating manner on the left and right sides, and the top of the bottom frame 1 is provided with an installation frame 3. It also includes a swing bar 4, an outer cylinder body 5, a second roller 6, a push handle frame 61 and a charging mechanism 7 for adorning rice, and the left side of the installation frame 3 is provided with a swing bar 4 in a rotating manner on the front and rear sides. An outer cylinder 5 is arranged between the tail ends of the swing rods 4 on the front and rear sides, the lower part of the outer cylinder 5 is open, the bottom of the left side of the outer cylinder 5 is provided with a second roller 6, and the left side of the installation frame 3 is provided with a push handle The frame 61 and the push handle frame 61 are c...

Embodiment 2

[0025] refer to figure 1 and image 3 , also includes a dumping mechanism 8, and the dumping mechanism 8 includes a first gear 81, a second gear 82, a scroll spring 83, a first slider 84, a connecting rod 85, a roller 86 and a U-shaped pedal 87, and the installation Frame 3 is equipped with first gear 81 in a rotating manner on both sides, front and rear, and second gear 82 is installed at the head end of swing lever 4. Second gear 82 is connected with swing lever 4 through interference connection. First gear 81 and The second gear 82 meshes, and a scroll spring 83 is connected between the second gear 82 and the installation frame 3. The scroll spring 83 is set on the outside of the swing rod 4, and the front and rear sides of the installation frame 3 are slidingly provided with first sliders. 84, the first slider 84 can vertically reciprocate and slide on the installation frame 3, a connecting rod 85 is arranged in a rotating manner between the front side of the first slider...

Embodiment 3

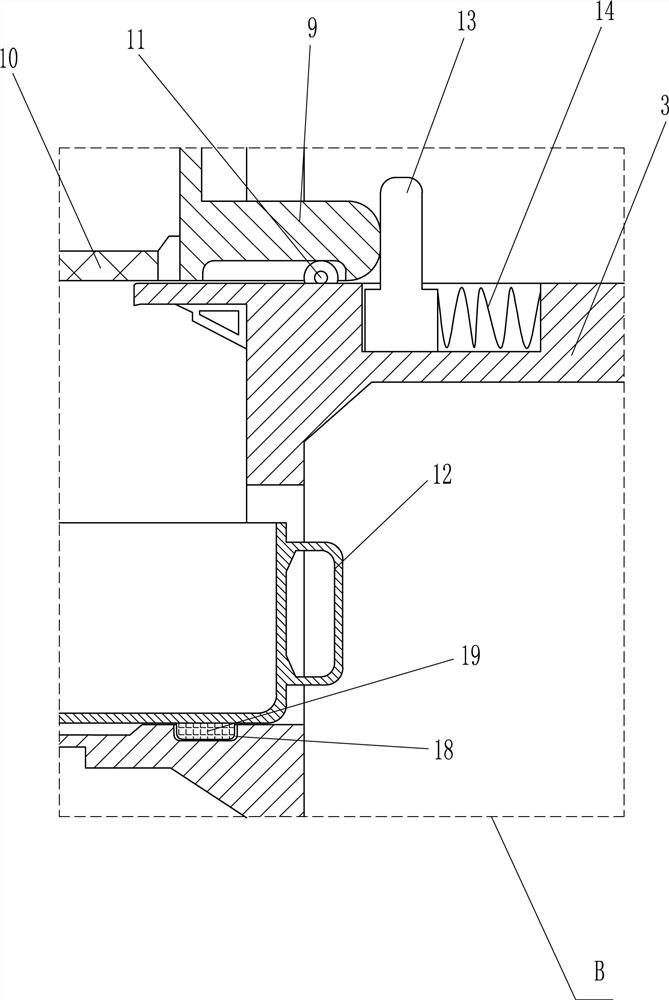

[0028] refer to Figure 4, also includes collecting frame 9, screen plate 10, third roller 11 and ash storage frame 12, and the upper part of installation frame 3 is slidably provided with collection frame 9, and collection frame 9 can slide back and forth in installation frame 3, and collection frame The inner bottom of 9 is provided with a mesh plate 10, the top right side of the installation frame 3 is rotatably provided with a third roller 11, the bottom of the collection frame 9 is in contact with the third roller 11, and the lower part of the installation frame 3 is slidingly provided with an ash storage frame 12, The ash storage frame 12 can slide back and forth in the installation frame 3 .

[0029] When the rice falls into the collection frame 9, the user pulls the collection frame 9 left and right to screen the rice, so that the dust in the rice falls into the ash storage frame 12 through the mesh plate 10, and the third roller 11 can make the collection frame 9 bett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com