A kind of industrial gearbox cleaning oil composition

A composition and gearbox technology, applied in the field of lubricating oil, can solve problems such as incompatibility, pollution, and restricting the effect of cleaning and changing oil, and achieve a good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0030] Example 1-3 The specific components of the industrial gear box cleaning oil are shown in Table 1, and the product performance is shown in Table 2:

[0031] Table 1

[0032]

[0033]

[0034] Table 2

[0035]

Embodiment 4-6

[0037] Example 4-6 The specific components of the industrial gear box cleaning oil are shown in Table 3, and the product performance is shown in Table 4:

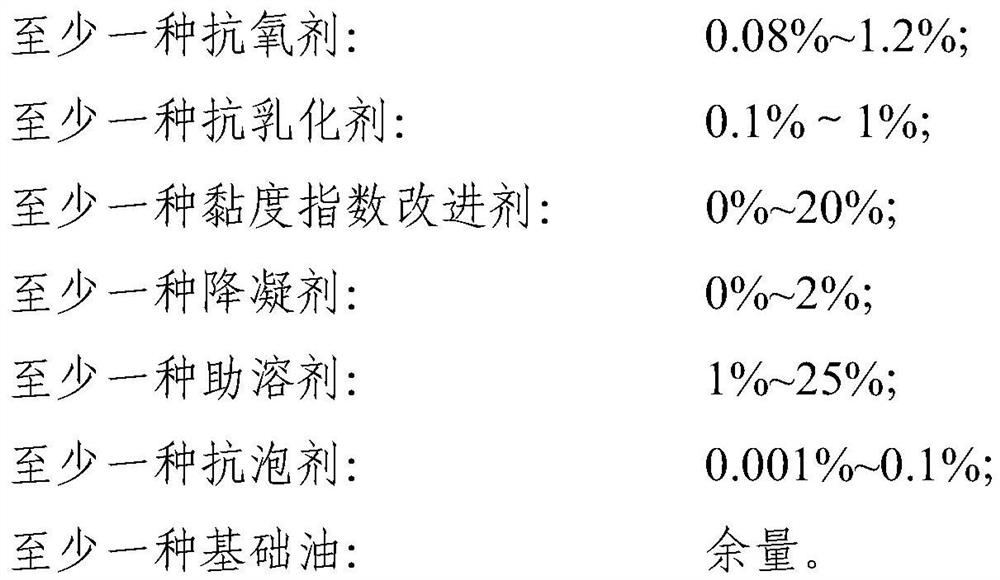

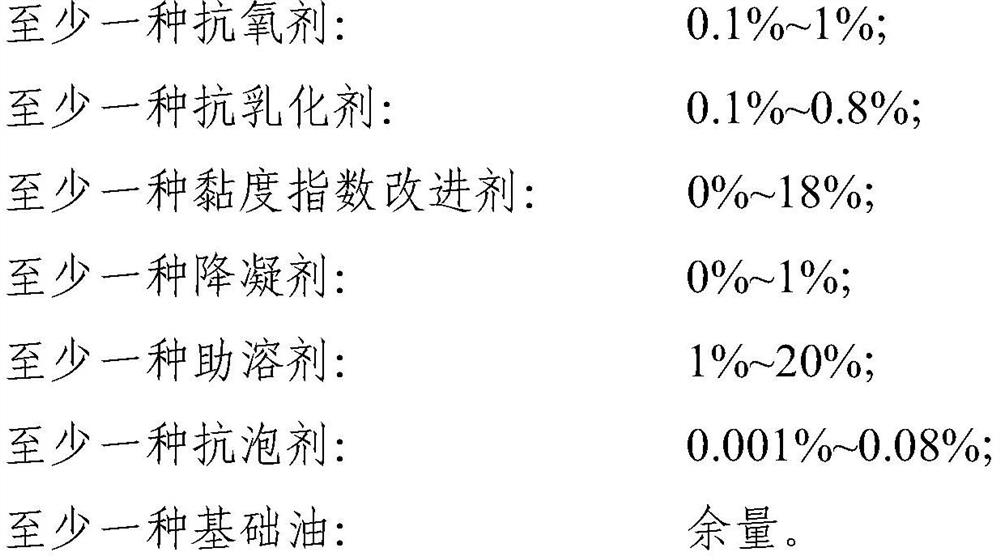

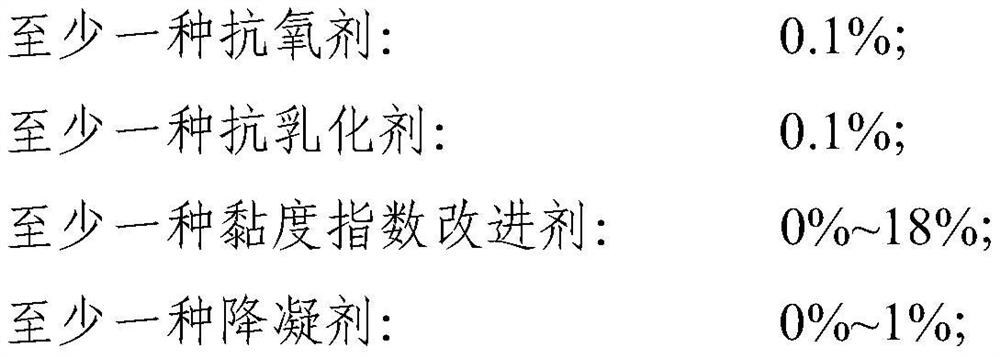

[0038] table 3

[0039]

[0040]

[0041] Table 4

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com