Industrial gear box cleaning oil composition

A composition and gear box technology, applied in the field of lubricating oil, can solve the problems of incompatibility, high cost, and reduce the performance of new oil in many aspects, and achieve the effect of good compatibility

Active Publication Date: 2020-01-17

CHINA PETROLEUM & CHEM CORP

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The mixing of old oil can also reduce the performance of new oil in many aspects, which will cause harm to the normal operation of the transmission system. What's more, the residual old oil is incompatible with the new oil, which may contaminate and block the entire lubrication system and damage the lubrication system. Seriously endanger the health of equipment

[0005] In some special fields such as wind turbines, large vertical mill main reducers, etc., the cleaning and oil change process is difficult to operate, takes a long time, consumes a lot of oil, and costs a lot. These objective factors restrict the effect of cleaning and oil change

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-3

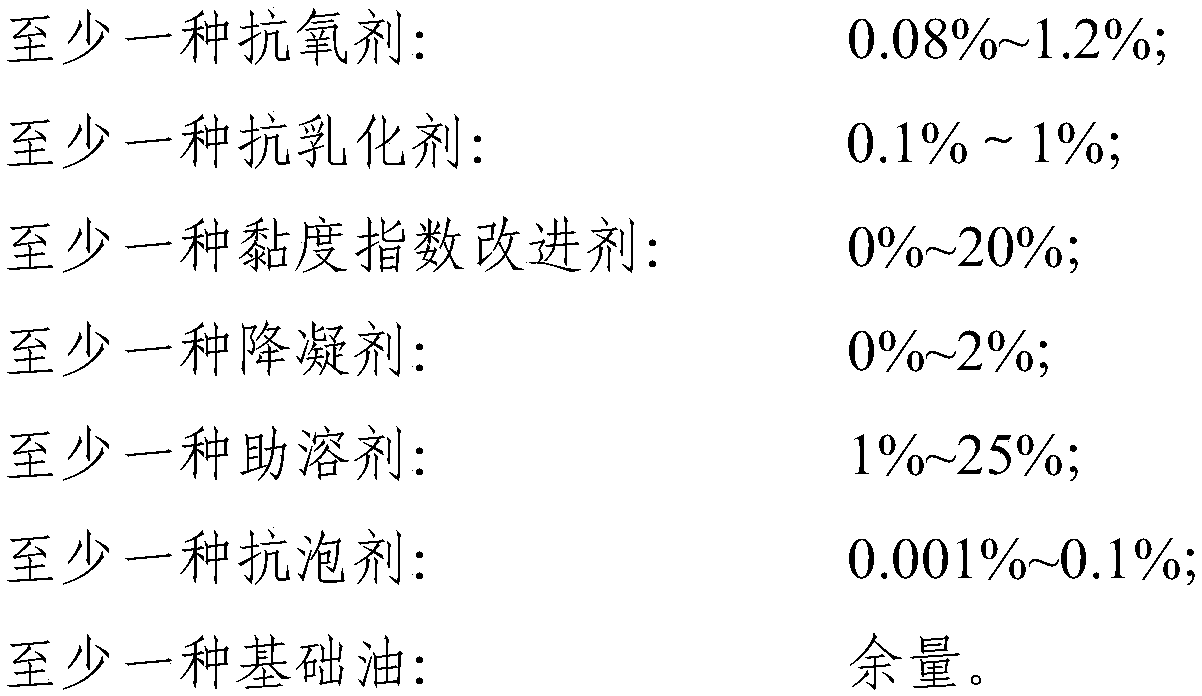

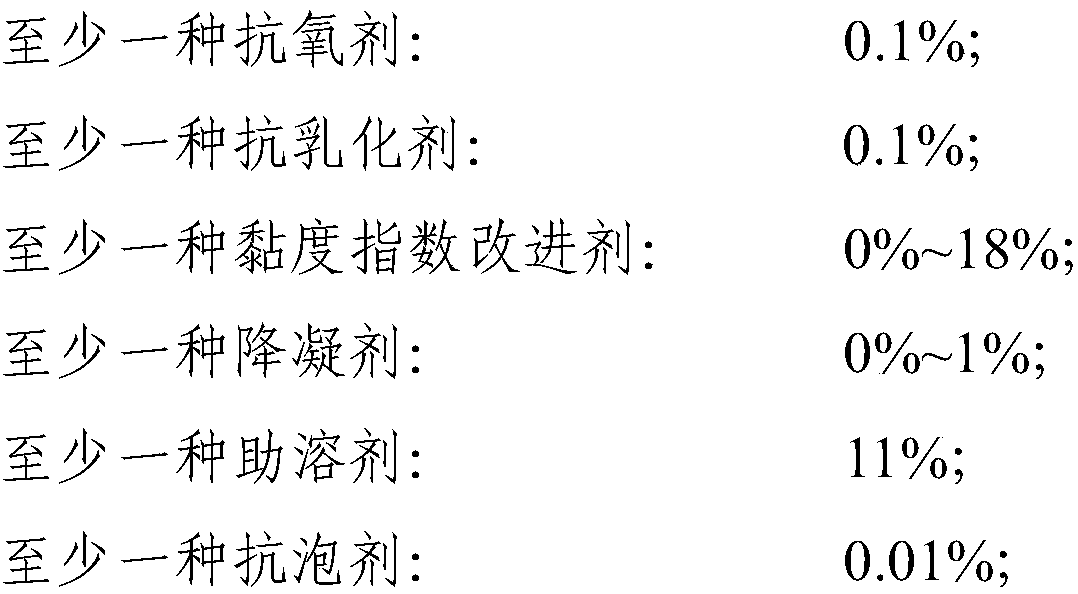

[0030] Examples 1-3 The specific components of industrial gearbox cleaning oil are shown in Table 1, and the product performance is shown in Table 2:

[0031] Table 1

[0032]

[0033]

[0034] Table 2

[0035]

Embodiment 4-6

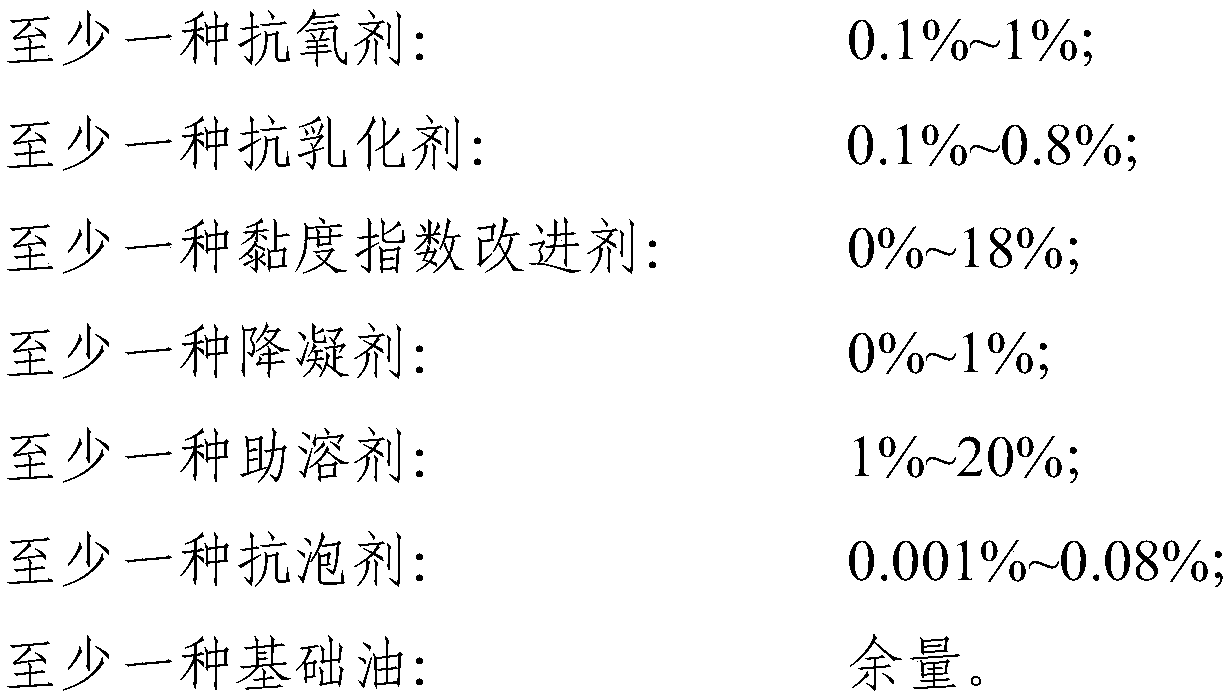

[0037] Examples 4-6 The specific components of industrial gearbox cleaning oil are shown in Table 3, and the product performance is shown in Table 4:

[0038] table 3

[0039]

[0040]

[0041] Table 4

[0042]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an industrial gear box cleaning oil composition which consists of the following components: at least one antioxidant, at least one emulsification inhibitor, at least one viscosity index improver, at least one pour point depressant, at least one cosolvent, at least one defoaming agent and at least one type of basic oil. The gear oil cleaning oil provided by the invention has properties of low temperature performance, emulsification inhibition, oxidation resistance and the like of typical industrial gear oil, but has remarkable characteristics different from those of common industrial gear oil that the oil product has good compatibility with a gear oil product in the market, is beneficial to dispersion of substances such as oily mud, organic acids and impurities andthus has a function of cleaning a gear box. Therefore, multiple problems caused in the oil product replacement process can be effectively alleviated.

Description

technical field [0001] The invention relates to the field of lubricating oil, in particular to a gearbox cleaning oil composition, which has excellent compatibility, oxidation resistance, emulsification resistance and the like, which are different from conventional industrial gear oils in use. Background technique [0002] As one of the mainstream transmission units, the industrial gearbox is the core part of many equipments. Therefore, the gear oil used for lubrication and protection in the gearbox should receive sufficient attention. [0003] With the development of industrial gear oil technology, the service life of oil products can be extended to more than 2500 hours or even longer. Under this condition, assuming that the design service life of the gearbox is 20 years, the gearbox will experience more than 60 years in the complete life cycle. The process of replacing new oil every time. And every new oil replacement is a key link that affects the life of oil products an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M169/04C10N30/02C10N30/04C10N30/08C10N30/10C10N30/12C10N40/04

CPCC10M169/04C10M169/048C10M2201/087C10M2203/1006C10M2205/0285C10M2207/026C10M2207/283C10M2209/104C10M2209/105C10M2229/02C10M2207/281Y02E10/72

Inventor 金吟杜雪岭安岸斐赵海鹏

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com