Direct-injection bio-based asphalt mixture warm-mixing agent as well as preparation method and application thereof

A technology of asphalt mixture and bio-based filler, which is applied in the field of asphalt additives, can solve the problems of poor reinforcement effect of inorganic reinforcing agent, poor thermal aging resistance, unstable performance, etc., to optimize low temperature performance, improve strength and compaction degree, the effect of improving the bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Formulation Design of Warm Mixing Agent

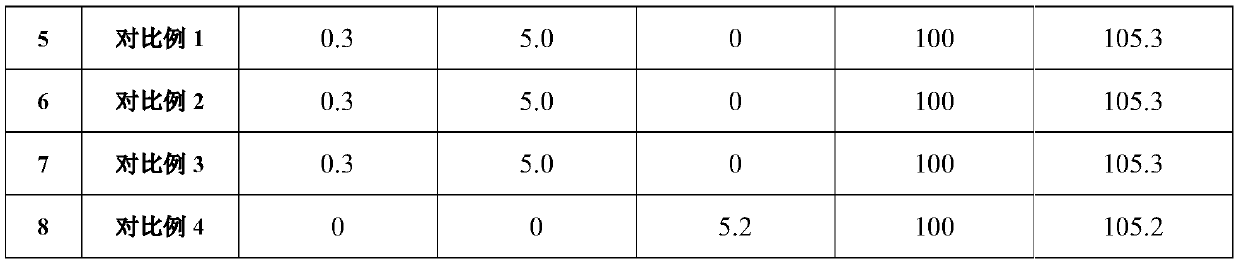

[0030] Below is the proportioning of embodiment 1-4 and comparative example 1-3, and concrete proportioning design is shown in Table 1:

[0031] Table 1: formulation design;

[0032] serial number polyolefin bio-based filler petroleum resin lubricant antioxidant total Example 1 73.8 8 12 5.8 0.4 100 Example 2 66.8 15 12 5.8 0.4 100 Example 3 60.8 8 25 5.8 0.4 100 Example 4 78.8 5 10 5.8 0.4 100 Comparative example 1 81.8 0 12 5.8 0.4 100 Comparative example 2 85.8 8 0 5.8 0.4 100 Comparative example 3 79.6 8 12 0 0.4 100

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com