A kind of cutting oil for titanium alloy processing and preparation method thereof

A cutting oil, titanium alloy technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of aggravated rake face wear, machined surface quality damage, high temperature activity and other problems, achieve good chemical protection, improved tool life, The effect of good lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

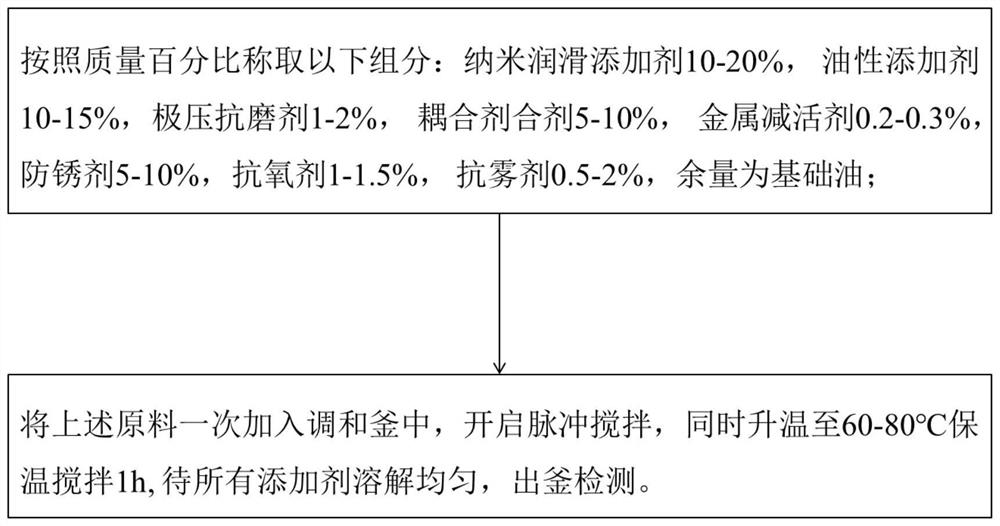

Method used

Image

Examples

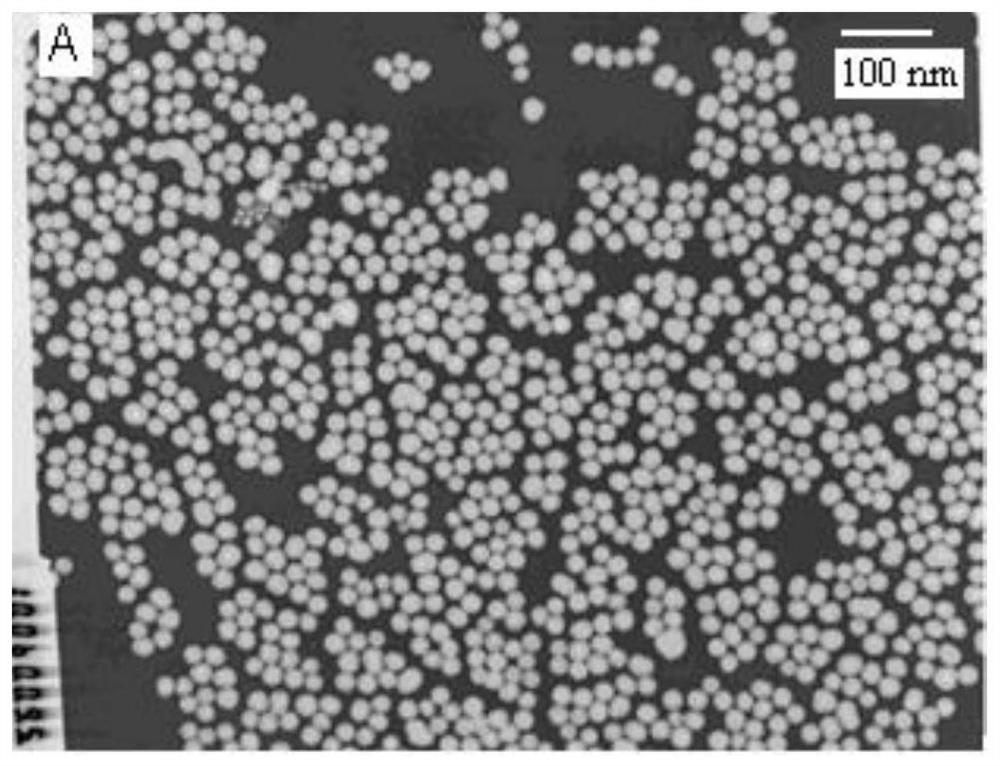

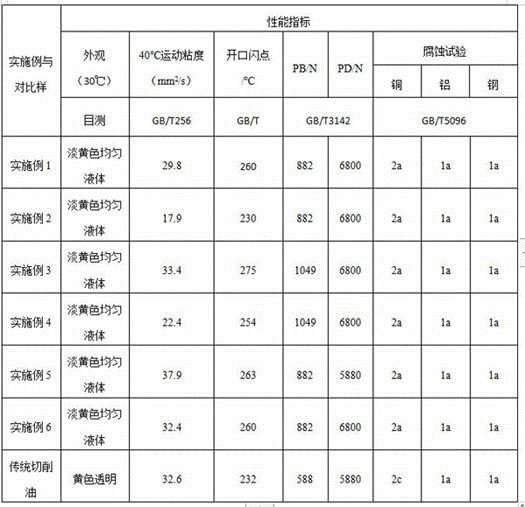

Embodiment 1

[0053] Turn on the stainless steel blending kettle for pulse stirring, raise the temperature to a temperature range of 60-70°C, add 67.3% base oil 150N, 60N (among them, the mass ratio of 150N to 60N is 1:1), and then add 10% of the surface to be modified by organic matter Oxygenated silica nanoparticles, 10% oxidized rapeseed oil and isooctyl oleate (the mass ratio of oxidized rapeseed oil to isooctyl oleate is 2:1), 5% diethylene glycol monobutyl ether, 0.2% Tolyl benzotriazole, 5% dodecenyl succinic acid, 1% 4,4-dioctyl diphenylamine, 1% inactive vulcanized extreme pressure antiwear agent, 0.5% molecular weight is 15000 polyisobutylene, after all the additives are added, keep stirring at 70°C for 1 hour, wait for all the additives to dissolve evenly, and test the main performance indicators to pass the test, then pack it out of the kettle.

Embodiment 2

[0055] Turn on the stainless steel mixing kettle for pulse stirring, raise the temperature to a temperature range of 60-70°C, add 53.7% base oil 60N, then add 10% of silica nanoparticles whose surface has been modified with organic matter, 15% of vegetable oil and trimethylol propane oleic acid monoester (mass ratio of vegetable oil to trimethylolpropane oleic acid monoester is 3:1), 7% diethylene glycol monobutyl ether, 0.3% methyl benzotriazole, 10 % of dodecenyl succinic acid, 1.5% of 4,4-dioctyl diphenylamine, 1% of inactive vulcanized extreme pressure antiwear agent, 1.5% of polyacrylate with a molecular weight of 15000, after all additives are added After completion, keep stirring at 70°C for 1 hour. After all the additives are dissolved evenly and the main performance indicators pass the test, they are taken out of the kettle for packaging.

Embodiment 3

[0057] Turn on the stainless steel mixing tank for pulse stirring, raise the temperature to 60-70°C, add 49.55% base oil 150N, add 15% silica nanoparticles whose surface has been modified with organic matter, 12% isooctyl oleate, 10% diethylene glycol monobutyl ether, 0.25% methyl benzotriazole, 8% dinonyl naphthalene sulfonate, 1.2% 4,4-dioctyl diphenylamine and 2,4- Dimethyl-6-tert-butylphenol (mass ratio 1:3), 2% molybdenum dialkyldithiocarbamate, 2% methacrylate and styrene copolymer with a molecular weight of 10,000 and all additives After the addition is completed, keep stirring at 70°C for 1 hour. After all the additives are dissolved evenly and the main performance indicators pass the test, they are taken out of the kettle for packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com