Hydraulic detection system and method for secondary water supply device

A detection system and secondary water supply technology, applied in the water supply pipeline system, water supply device, water supply main pipeline, etc., can solve the problems of increased labor travel costs, unguaranteed equipment quality, and difficulty in on-site maintenance and replacement. The effect of inspection level, shortening engineering debugging time, reducing failure points and equipment hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

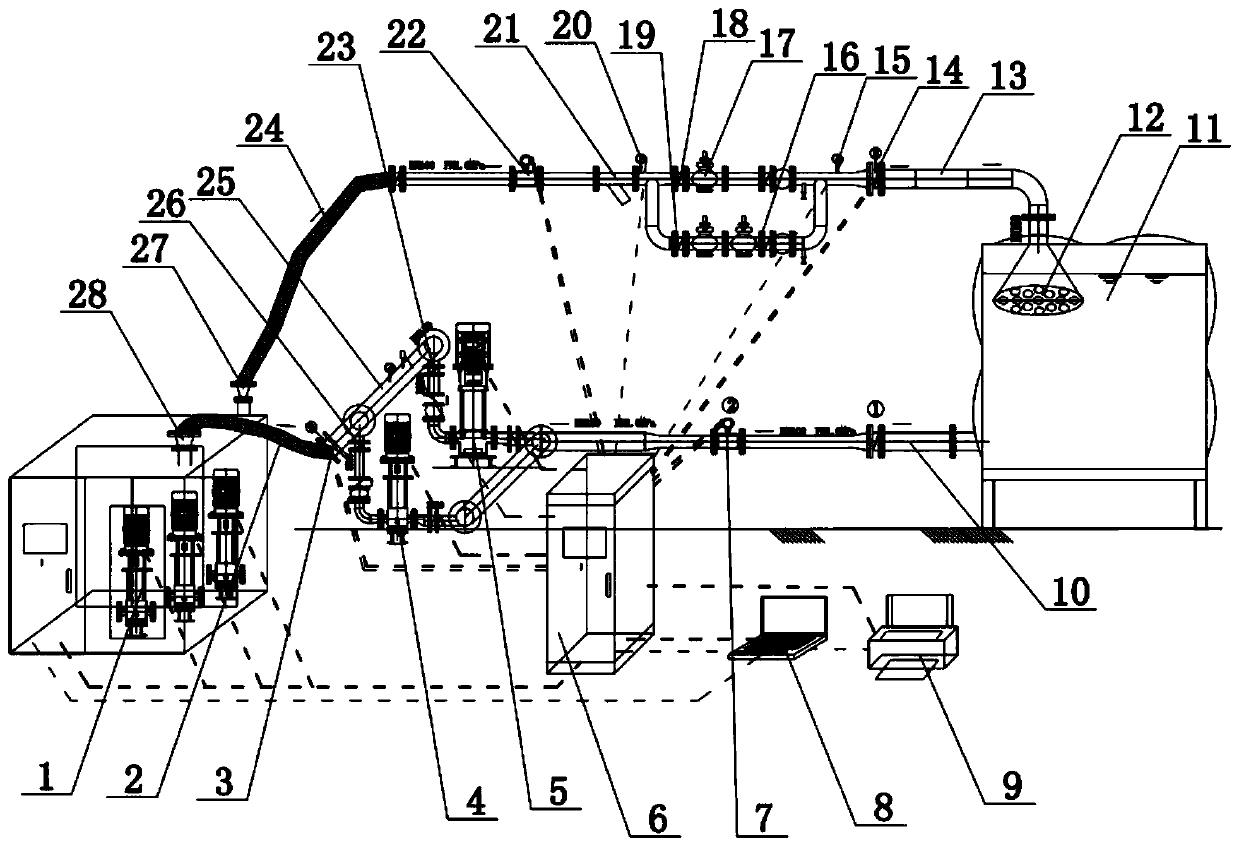

[0024] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings.

[0025] Such as figure 1 The hydraulic testing system for secondary water supply equipment shown includes a water tank 11 and a water inlet hose 2 and an outlet hose 24 connected to the equipment to be tested 1. The equipment to be tested 1 is connected to the frequency conversion cabinet to be tested. The upper end of the water tank 11 Connect the water return pipe 13, the side of the lower end of the water tank 11 is provided with a water outlet pipe 10, the water outlet electromagnetic flowmeter 7 and the on-off valve are respectively arranged on the water outlet pipe 10, and the water outlet pipe 10 is respectively connected with the first booster pipeline and the second booster pipeline. pressure pipeline, the first booster pipeline and the second booster pipeline merge into the outlet pipe 25 of the booster pump, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com