Timepiece component having shaft-like portion made of non-magnetic alloy

A non-magnetic, component technology that is used in the manufacture of watch oscillators, watch components and wheel sets, watch components, watch movements, and wheel sets, and can solve problems such as harmful power reserves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Unless otherwise stated, the compositions in this specification are compositions in mass percent.

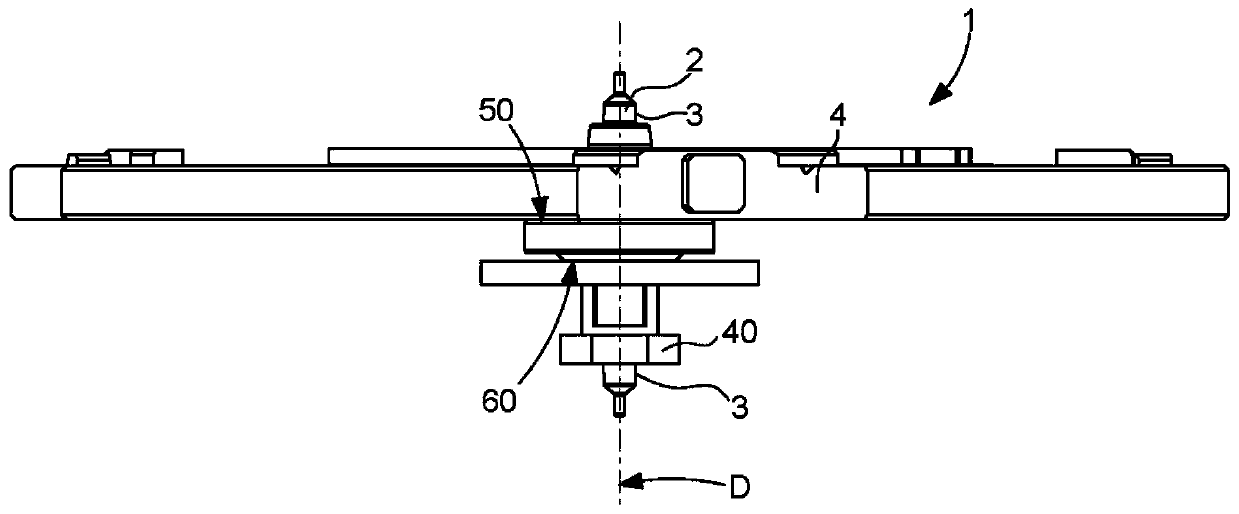

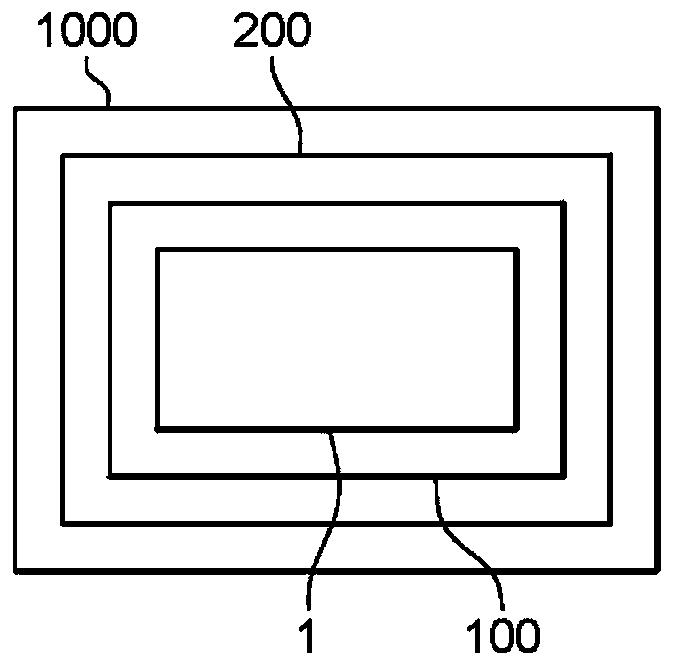

[0016] The invention relates to a timepiece component 1 , in particular a wheel set, comprising an axle-like portion 2 comprising at least one pivot 3 around a pivot axis D.

[0017] As for the material of the shaft portion, it is preferable that its Vickers hardness is between that of copper / beryllium alloy (380HV+ / −20) and that of 20AP steel or the like (740HV+ / −30).

[0018] According to the invention, at least the material forming the shaft-shaped portion 2 is a non-magnetic alloy containing at least silver and palladium and having a Vickers hardness greater than 450 HV.

[0019] In a particular embodiment, part 1 is completely non-magnetic.

[0020] In a particular embodiment, the shaft-like portion 2 runs through the entire length of the part 1 in the direction of the pivot axis D. As shown in FIG.

[0021] More specifically, the shaft-like portion 2 carries at le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com