Preparation method of through hole structure and preparation method of three-dimensional memory

A memory and three-dimensional technology, which is applied in the fields of electrical solid-state devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve problems affecting device reliability, SEG damage, and damage to epitaxial growth layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

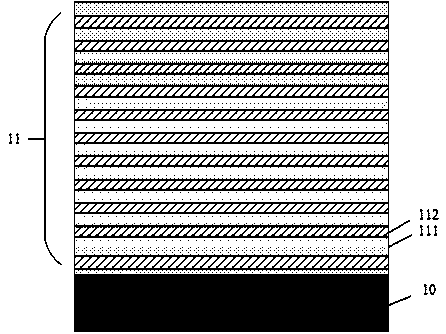

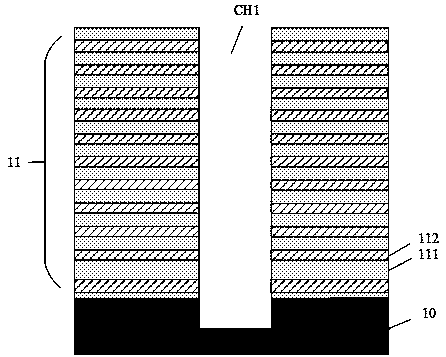

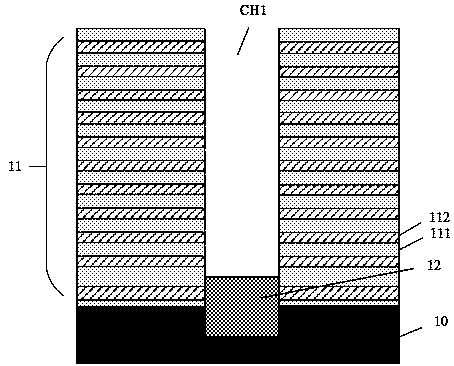

[0045] Based on this, an embodiment of the present invention provides a method for preparing a through-hole structure; for details, please refer to image 3 . As shown, the method includes the following steps:

[0046] Step 201, providing a base structure, the base structure including a first stacked layer;

[0047] Step 202, etching the first stacked layer to form a first through hole;

[0048] Step 203, forming an epitaxial growth layer at the bottom of the first through hole;

[0049] Step 204, forming an etching barrier layer in the first through hole, the etching barrier layer covering at least the surface of the epitaxial growth layer;

[0050] Step 205, forming a filling structure in the first through hole;

[0051] Step 206, forming a second stack layer on the first stack layer;

[0052] Step 207, etching the second stacked layer to form a second through hole communicating with the first through hole;

[0053] Step 208, etching to remove the filling structure in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com