Micro device transfer device and micro device transfer method

A technology for micro-devices and transfer devices, which is applied in the manufacturing of semiconductor devices, electric solid-state devices, and semiconductor/solid-state devices, etc., can solve problems such as breakage, and achieve the effect of improving uneven force and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

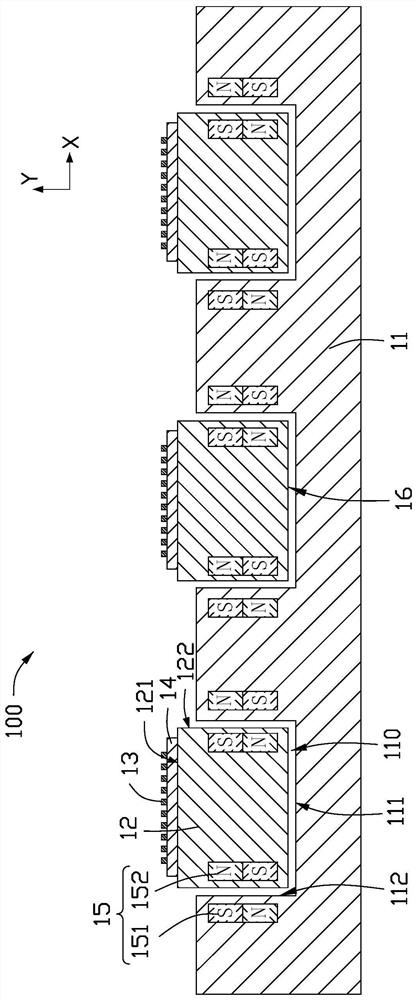

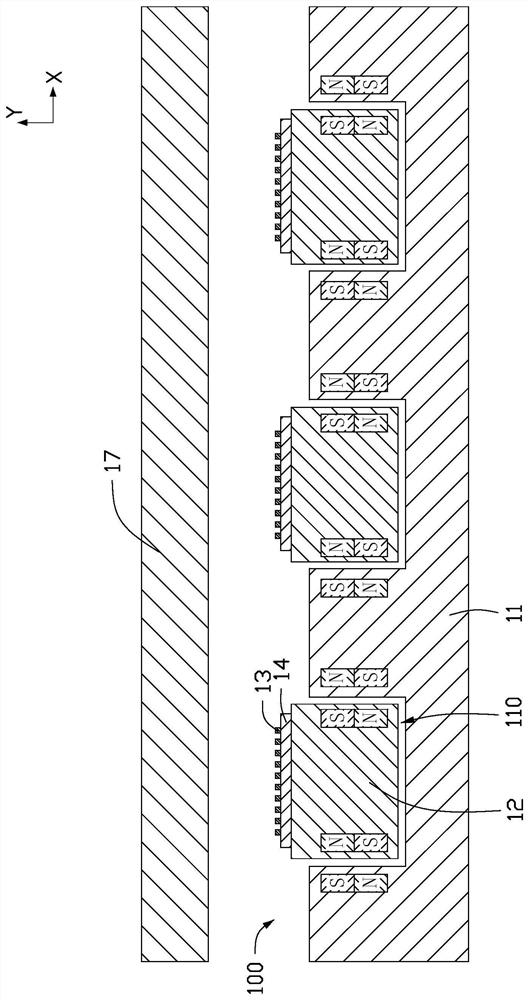

[0040] figure 1 is a schematic structural diagram of the transfer device 100 of the first embodiment. The transfer device 100 can be used for transferring microdevices 13 . Such as figure 1 As shown, the transfer device 100 includes a first substrate 11 . At least one well 110 is opened on a surface of the first substrate 11 . In this embodiment, a plurality of wells 110 are opened on a surface of the first substrate 11 , three wells 110 are shown in the figure. Each well 110 includes a first bottom surface 111. In this embodiment, the first bottom surface 111 is rectangular, but not limited thereto, and the shape of the first bottom surface is not limited. Each well also includes a first side wall 112 extending from four sides of the first bottom surface 111 toward the wellhead, and the first bottom surface 111 serves as a bearing surface. The first bottom surface 111 of each well is basically at the same height relative to the same horizontal plane or at slightly differ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com