An overhead rail shifting machine with an automatic rail-changing turntable

A technology of a lift and turntable mechanism, applied in medical science, hospital beds, hospital equipment, etc., can solve problems such as radio interference, cumbersome wiring, equipment repair and maintenance problems, etc., to achieve convenient maintenance, reduce costs, and avoid radio interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

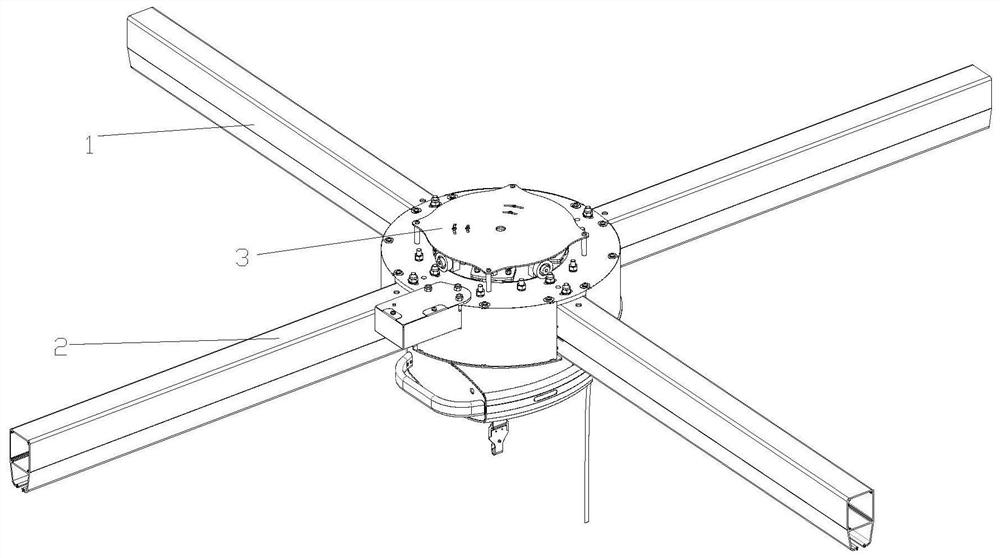

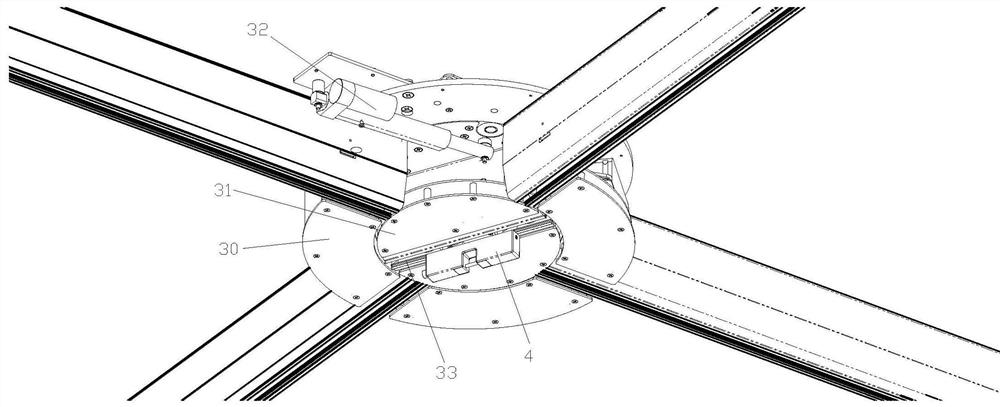

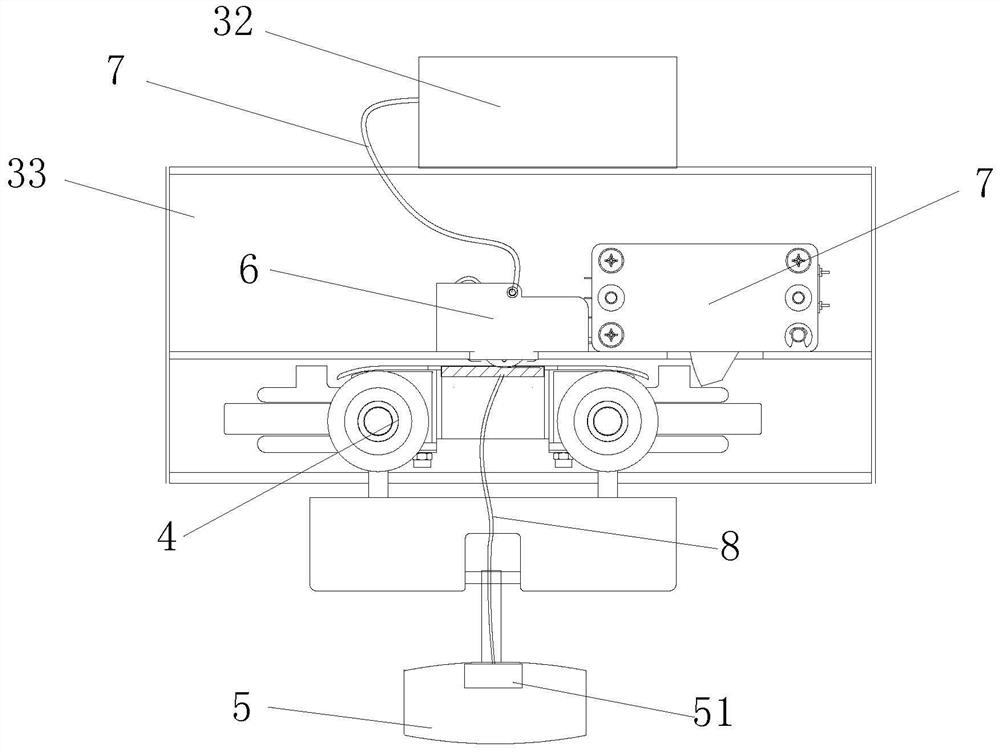

[0034] Example: such as Figure 1 ~ Figure 3 As shown, a sky rail shifting machine with an automatic track-changing turntable includes a first track 1, a second track 2, a track-changing turntable mechanism 3, a pulley mechanism 4 and a crane 5; the first track 1 and the second The track 2 forms a cross shape, and the track-changing turntable mechanism 3 is arranged at the cross center position of the first track 1 and the second track 2; On the first track 1 and the second track 2, a turntable 31 is rotatably arranged in the machine cover 30, and a push rod motor 32 is fixedly arranged in the machine cover 30, and the telescopic rod head of the push rod motor 32 is fixed on the turntable. 31; the turntable 31 is provided with a small transition track 33, the transition track 33 corresponds to the first track 1 and the second track 2, and the pulley mechanism 4 is movably arranged on the first track 1, the second track 2 and the transition track 33 Inside, the crane 5 is susp...

Embodiment approach

[0036] Such as Figure 4 As shown, the middle of the machine case 30 is a circular hollow part, and the rotating disk 31 is arranged in the circular hollow part; a plurality of outer roller support structures 34 are evenly arranged around the outer edge of the rotating disk 31, and a circle around the outer edge of the rotating disk 31 The ring is also evenly provided with several inner roller rotating structures 35; the outer roller support structure 34 includes a support base and vertically placed rollers, and the vertically placed rollers are fixed on the turntable 31 through the support base, while the vertically placed rollers are against the The upper end surface of the machine case 30; the inner roller rotating structure 35 includes a fixed seat and a horizontally placed roller, the horizontally placed roller is fixed on the rotating disk 31 through the fixed seat, and the horizontally placed roller is located in the middle of the rotating disk 31 and the machine casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com