System applied to detecting tension of steel wire of wire winding mechanism

A wire winding machine and tension technology, applied in tension measurement, transportation of filamentous materials, thin material processing, etc., can solve the problems of inconvenient wiring, low measurement accuracy, and the detection device cannot directly reflect the size of the tension, etc. Achieve the effect of simple wiring, high detection accuracy and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

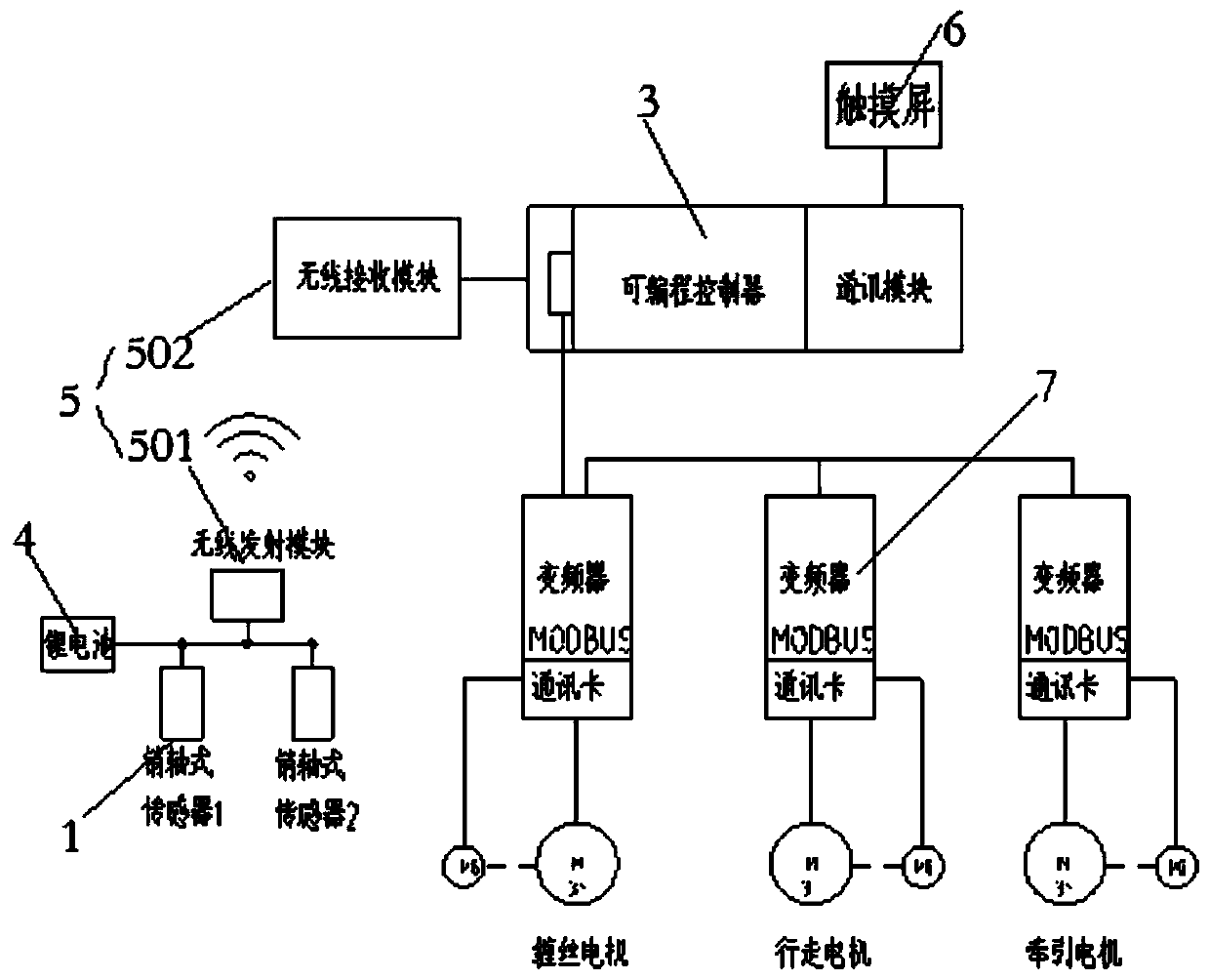

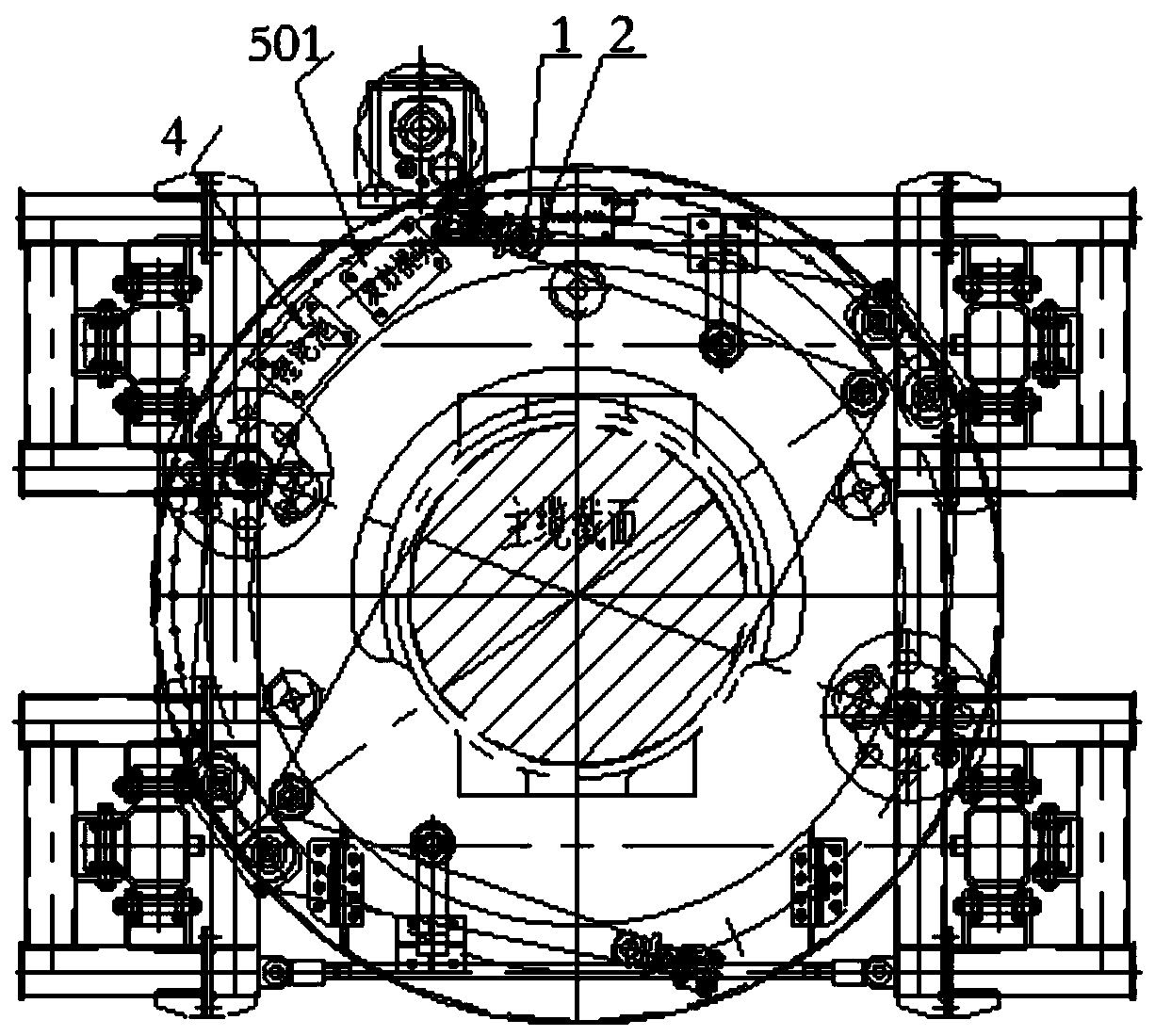

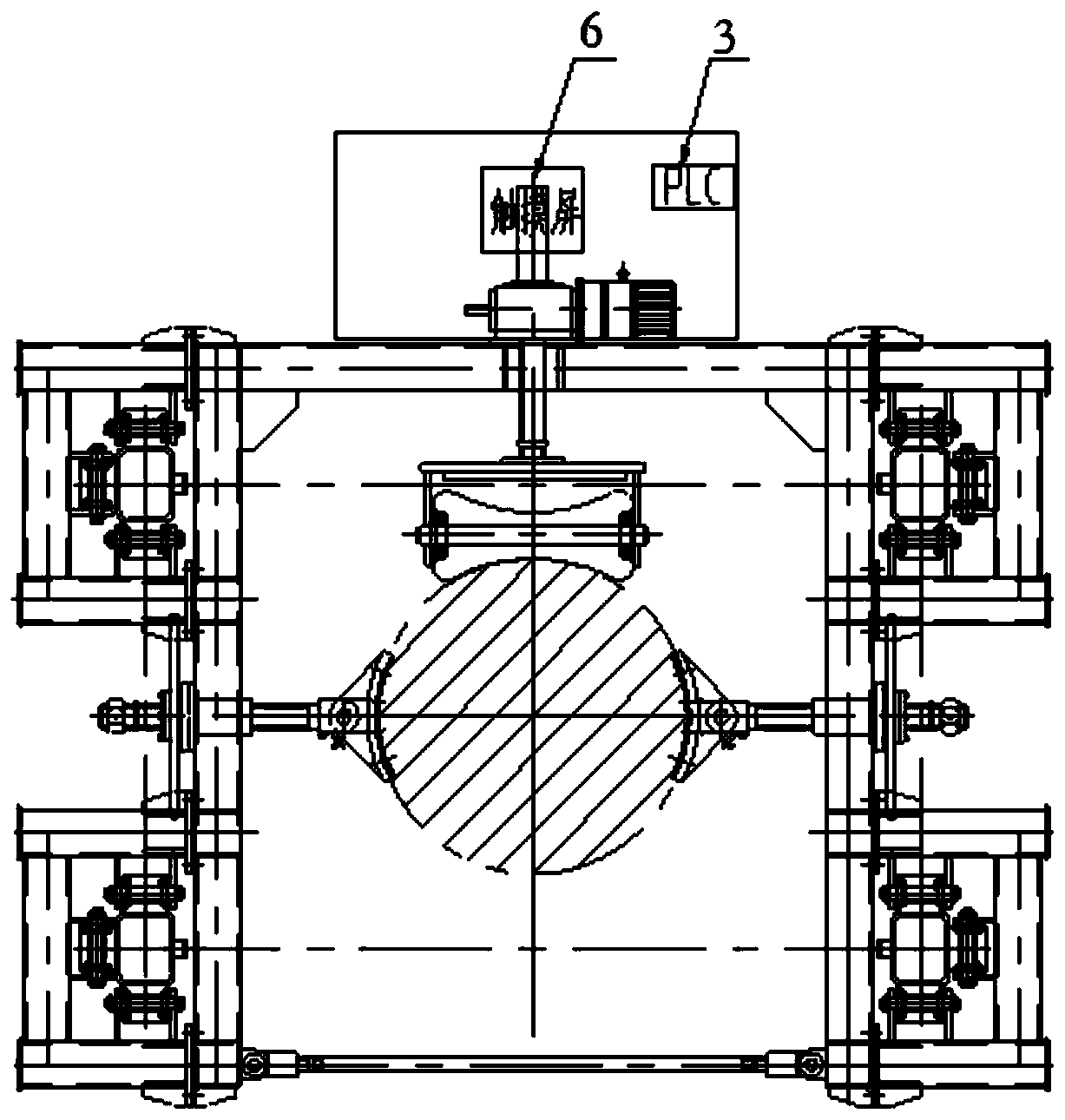

[0027] On a wire winding machine with a maximum wire diameter of 1350mm, the wire tension detection system adopts this kind of wire tension detection system, the maximum winding tension is 3.2KN, double-ended wire winding, and two pin sensors with a measuring range of 0.8T are used 1 , respectively installed on the two guide pulleys 2 on the large gear ring, the pin sensor 1 is deformed under force, and the deformation variation is proportional to the tension function. The transmitting module 501 on the circle performs digital processing and high-efficiency forward error correction coding, and then sends it to the receiving module 502 in the form of radio after FSK high-frequency modulation. After receiving the signal, the receiving module 502 demodulates and decodes the signal. It is sent to the programmable controller 3, and after being processed by the programmable controller 3, it is sent to the touch screen 6 for display. The display accuracy is 0.01KN. When the tension va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com