Control system of hot die forging press

A hot die forging press and control system technology, applied in the field of press control, can solve the problems of low display accuracy of the sealing height display device, alarm of inverter bus voltage rise, cumbersome wiring of CPU module, etc., so as to avoid bus voltage Too high, to avoid mutual interference, improve the effect of line stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

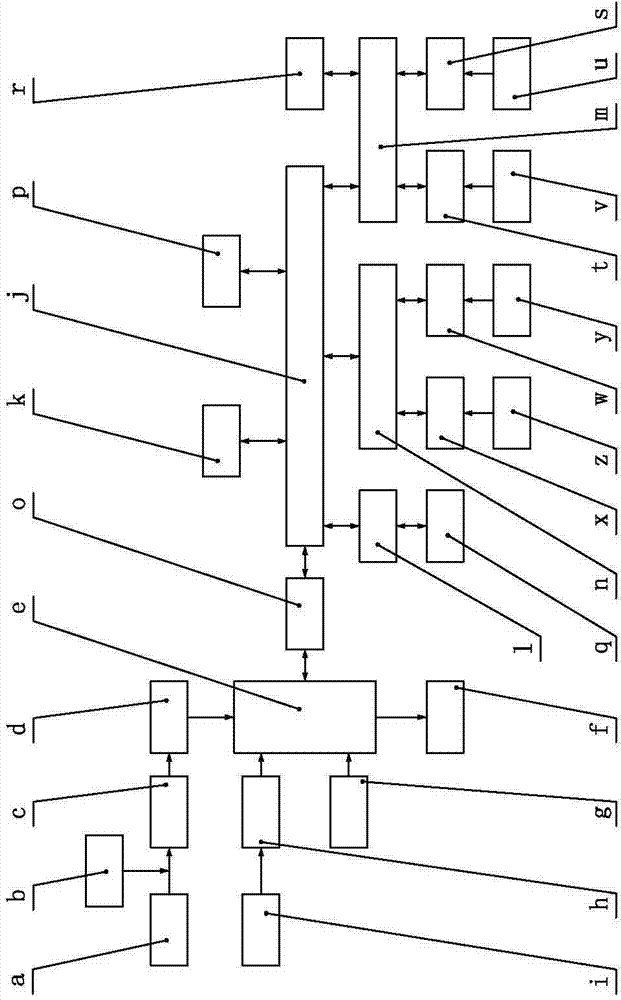

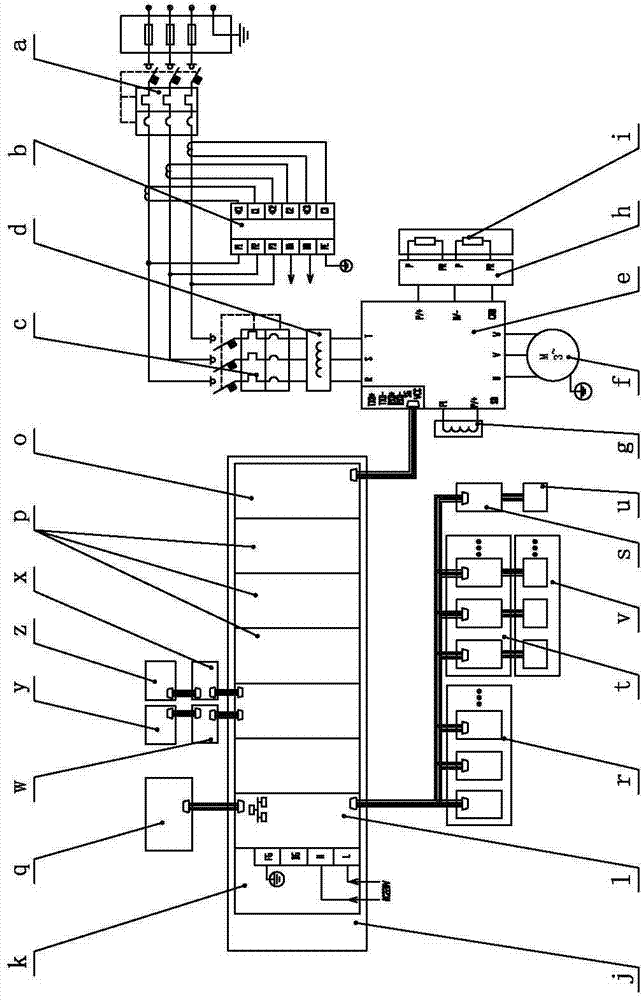

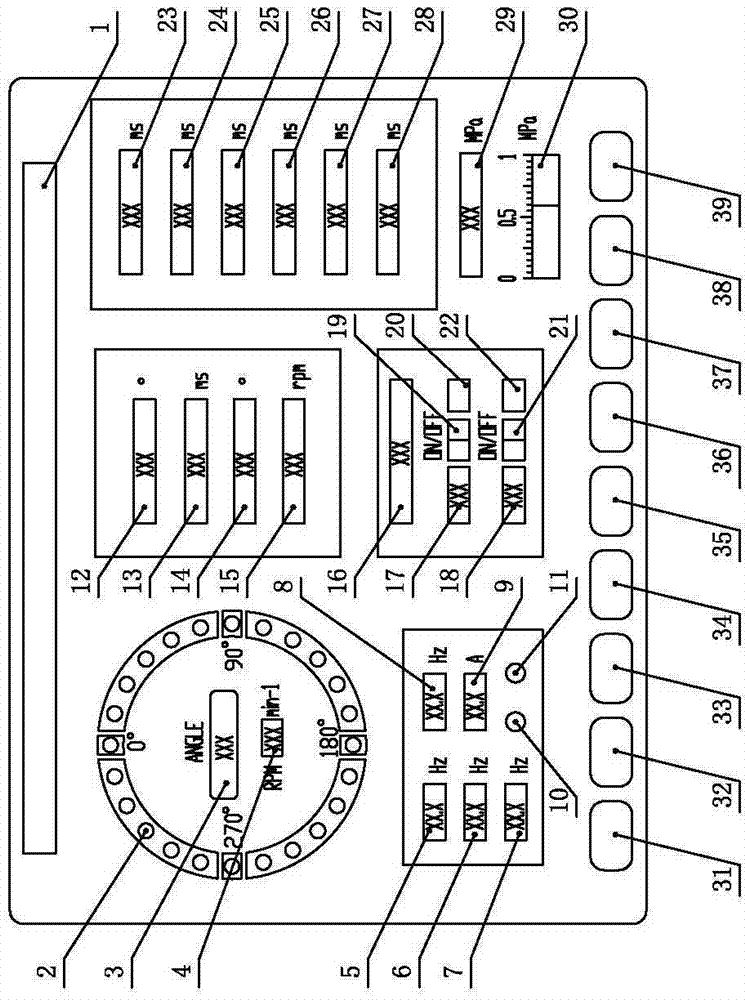

[0022] like figure 1 and figure 2 As shown, the control system of the hot die forging press of the present invention includes a three-phase power supply, a frequency converter e, a main motor f and a CPU module l, and the three-phase power supply sequentially passes through a circuit breaker a, a leakage protector c, an AC reactor d and The AC power input terminal of the frequency converter e is connected, the AC power output terminal of the frequency converter e is connected with the main motor f, and the output shaft of the main motor f is connected with the flywheel drive of the press. A multi-function meter b is also connected to the line connecting circuit breaker a to leakage protector c to monitor the power usage status of the system. The P / +, N / - and CN8 terminal blocks of the inverter e are connected to the external braking unit h, the P1 and P / + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com