Autoclaved aerated concrete block for integrated wall surface system and preparation method thereof

A concrete block, autoclaved aeration technology, applied in the direction of walls, applications, household appliances, etc., can solve the problems of abnormal noise, block resonance and abnormal noise, and large changes in wind pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

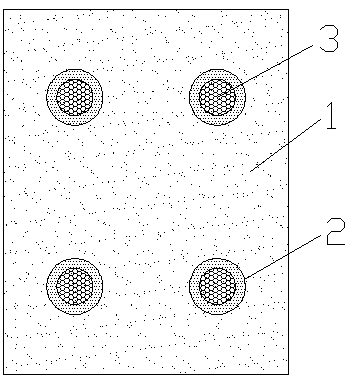

[0029] figure 1 An autoclaved aerated concrete block for an integrated wall system is shown, in the figure: 1. Block body, 2. Reinforcing rib, 3. Polyurethane foam. The structure is: there are several reinforcing ribs in the block body, and polyurethane foam is arranged in each reinforcing rib;

[0030] In one of the production methods, the raw materials used for the block body include by mass:

[0031] 50 parts of fly ash, 15 parts of Portland cement, 15 parts of quartz weathered sand, 12 parts of basalt powder, 11 parts of lime powder, 6 parts of yellow sand, 7 parts of gypsum, 4 parts of sodium lignosulfonate, 2.5 parts of sodium sulfate , 1 part of aluminum powder paste;

[0032] Described stiffener raw material comprises by mass:

[0033] 45 parts of fly ash, 17 parts of Portland cement, 16 parts of lime powder, 9 parts of silica powder, 8 parts of graphite fiber, 6 parts of yellow sand, 5 parts of gypsum, 5 parts of sodium lignosulfonate, 3 parts of sodium sulfate pa...

example 2

[0049] figure 1 An autoclaved aerated concrete block for an integrated wall system shown, another production method:

[0050] The raw materials used in the block body include by mass:

[0051] 55 parts of fly ash, 20 parts of Portland cement, 15 parts of quartz weathered sand, 12 parts of basalt powder, 14 parts of lime powder, 7 parts of yellow sand, 6 parts of gypsum, 5 parts of sodium lignosulfonate, 3 parts of sodium sulfate , 1.2 parts of aluminum powder paste;

[0052] Rib raw materials include by mass:

[0053] 40 parts of fly ash, 20 parts of Portland cement, 13 parts of lime powder, 10 parts of silica powder, 10 parts of graphite fiber, 5 parts of yellow sand, 4 parts of gypsum, 6 parts of sodium lignosulfonate, 3 parts of sodium sulfate part, 1.4 parts of aluminum powder paste;

[0054] The method of preparing the reinforcement is as follows:

[0055] (1) Mix fly ash, silica powder, yellow sand, and gypsum with water to make a slurry according to the ratio of pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap