Polyarylene sulfide composition having excellent adhesion to metals

A technology of polyarylene sulfide and resin composition, which is applied in the field of polyarylene sulfide composition, can solve the problems of reducing the mechanical properties of PPS, weakening thermal characteristics, etc., and achieve excellent mechanical and thermal properties, and excellent metal adhesion properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0075] Preparation example: preparation of PPS

[0076]In a 5 L reactor equipped with a thermocouple for measuring the internal temperature of the reactor and a vacuum line for filling nitrogen and creating a vacuum, a mixture containing 5,130 g of p-diiodobenzene (p-DIB) and 450 g of sulfur was heated to 180°C to completely melt and mix. By initiating the reaction at 220 °C and 350 Torr, and gradually increasing the temperature and reducing the pressure for 4 hours to the final conditions of 300 °C and 0.6-0.9 Torr, and by injecting 7 times of sulfur and 19 g each, the mixed The reactants undergo a polymerization reaction. When the polymerization reaction has progressed to about 80% (the extent of the polymerization reaction is determined by "(current viscosity / target viscosity)×100"), that is, the relative ratio of the current viscosity to the target viscosity. The current viscosity was measured by taking a sample during the polymerization, and the target viscosity was s...

Embodiment 1

[0086] Embodiment 1: prepare PPS resin composition

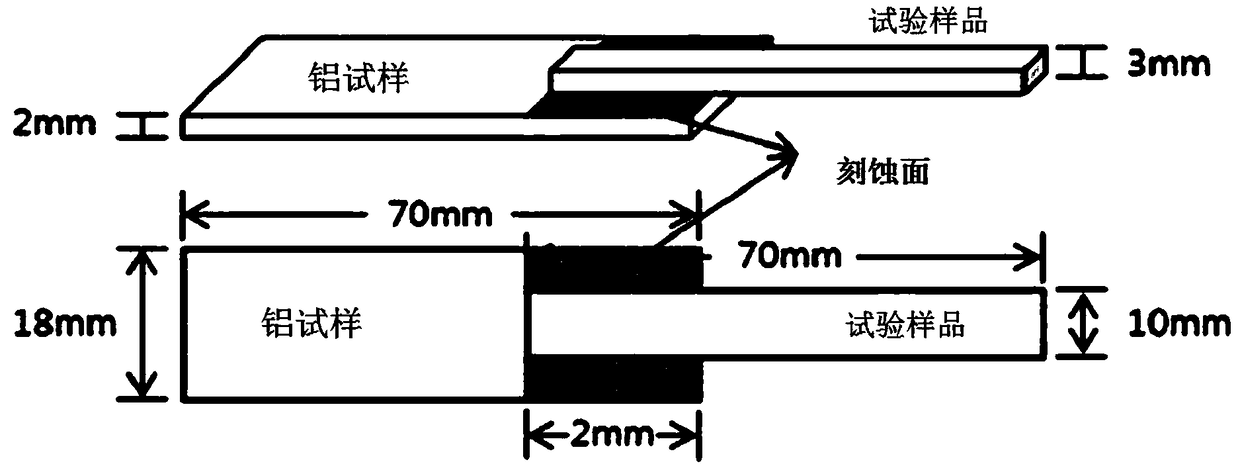

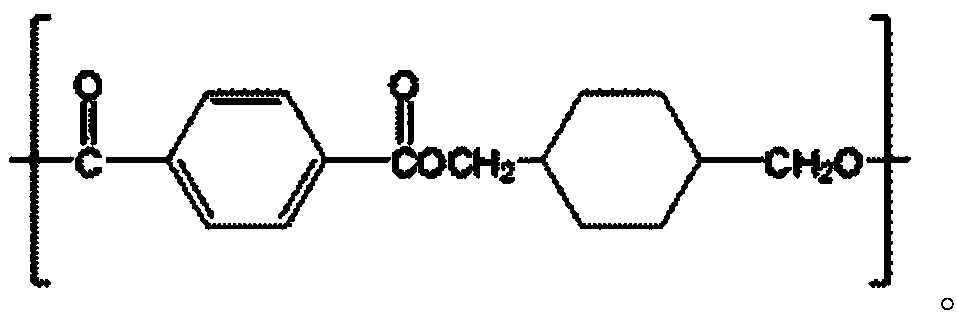

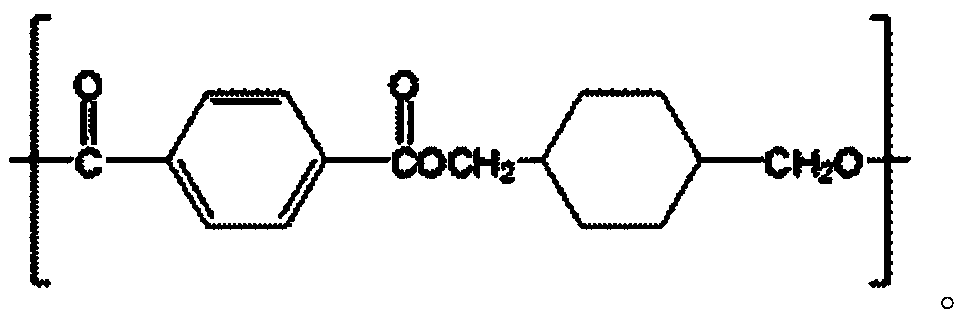

[0087] In a twin-screw extruder, to 100 parts by weight of the PPS resin obtained in the preparation example, 9 parts by weight of PCT resin (manufacturer: SK Chemicals, product name: 0302, weight average molecular weight: 56,000, intrinsic viscosity (IV): 0.65dl / g, and the L value measured using a spectrocolorimeter at the D65 light source including the specular component mode is 90), 9 parts by weight of phenoxy resin (manufacturer: InChem Co., product name: PKHH, weight average molecular weight: 52,000, glass transition temperature: 92° C.), 25 parts by weight of glass fiber treated with epoxysilane (manufacturer: Owens corning Co., product name: V-910), 9 parts by weight of ZnS (manufacturer: Sachtleben Co., product name: Sachtolith) as a white pigment and 13 parts by weight of elastomer (manufacturer: Arkema Co., product name: Lotader AX-8900, glycidyl methacrylate, acrylate and ethylene terpolymers) to prepare PPS res...

Embodiment 2-5 and comparative example 1

[0090] The PPS resin composition was prepared according to the same steps described in Example 1, except that the components and their amounts are shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com