Preparation method of semiconductor film field effect transistor made of unstable two-dimensional material

A thin-film field effect, two-dimensional material technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve the problems of high alignment difficulty, extraction error, small production device yield, etc., and achieves low manufacturing process difficulty, The effect of small electrical hysteresis and no performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

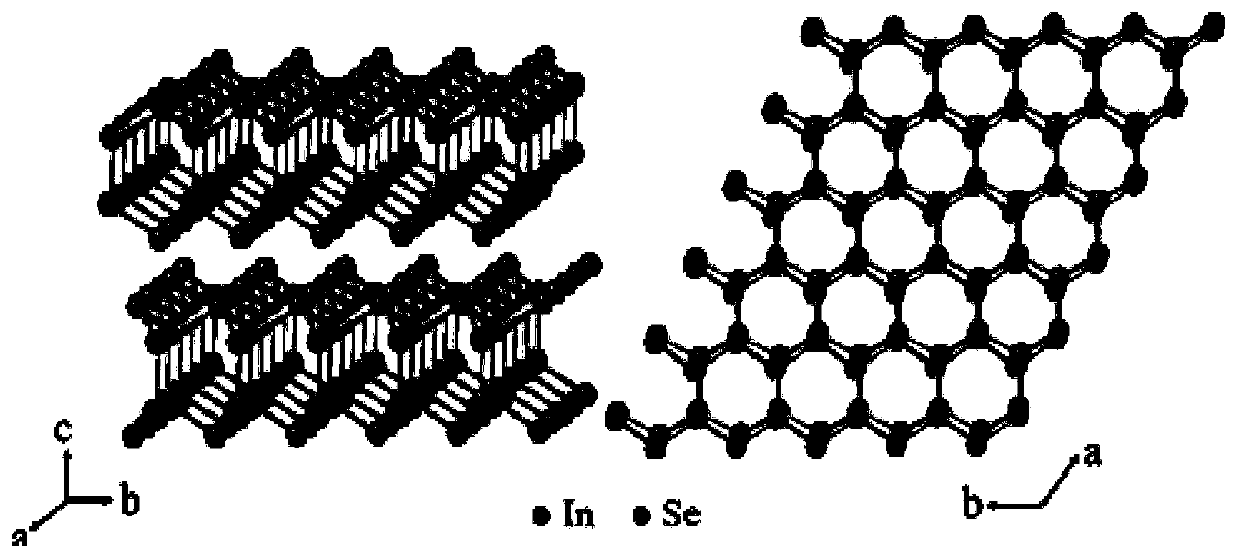

[0058] A method for preparing a semiconductor thin film field effect transistor of an unstable two-dimensional material. The semiconductor thin film field effect transistor includes a silicon wafer substrate, an unstable two-dimensional material, a hafnium oxide film, an aluminum oxide film, and a source from bottom to top. and drain, such as Figure 4 shown, including the following steps:

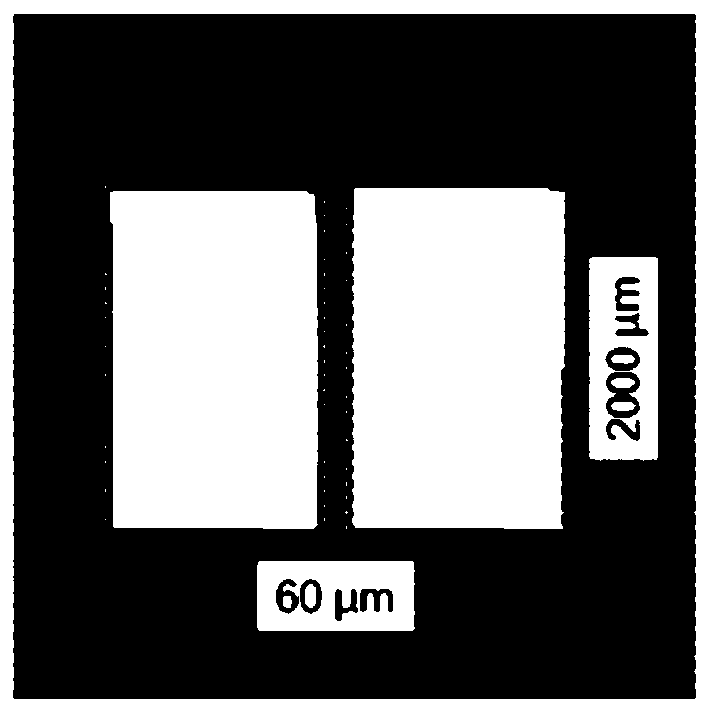

[0059] (1) A silicon wafer substrate with an alignment mark is produced by photolithography as a transfer base;

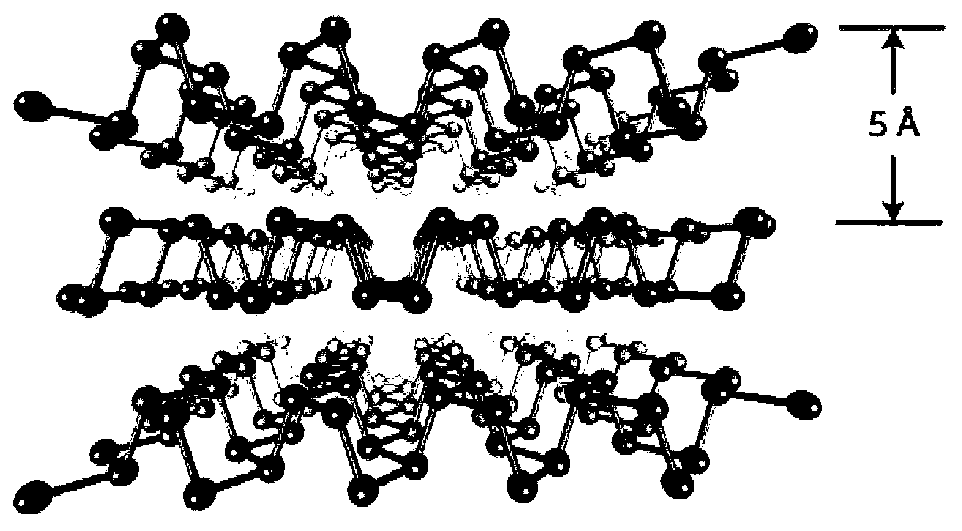

[0060] (2) A mechanical stripping method is used to strip several times with adhesive tape to prepare a two-dimensional InSe material with a thickness of 20-80 nm. Transfer the 20-80nm two-dimensional material to the silicon wafer substrate; that is: the high-quality master material prepared by the Bridgman method is torn with adhesive tape multiple times, so that the randomly distributed InSe nanosheets reach a thickness of 20-80nm , and then transfer the two-dimensional mat...

Embodiment 2

[0071] According to the preparation method of the semiconductor thin film field effect transistor of a kind of unstable two-dimensional material described in embodiment 1, its difference is:

[0072] In step (4), the thickness of the aluminum oxide film is 20-40nm. The deposition temperature is 130-180°C.

[0073] In step (3), the hafnium oxide thin film has a thickness of 3-7nm.

Embodiment 3

[0075] According to the preparation method of the semiconductor thin film field effect transistor of a kind of unstable two-dimensional material described in embodiment 1, its difference is:

[0076] In step (4), the thickness of the aluminum oxide film is 30nm. The 30nm alumina can play a better isolation effect, so that the process solvent and air have less influence on the semiconductor material, and at the same time, the photoresist will not be etched too much due to the relatively small etching selection during the rear etching. This results in difficulty in electrode stripping. The deposition temperature was 150°C. At 150°C, the film quality of aluminum oxide film is higher.

[0077] In step (4), the device obtained in step (2) is placed in an atomic layer deposition device (ALD), and an aluminum oxide film is deposited on the surface of the device obtained in step (3); the carrier gas of the atomic layer deposition device has a purity greater than 99.999% high-purity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com