In-situ curing electrolyte, gel lithium ion battery and preparation method thereof

An in-situ curing, electrolyte technology, applied in the field of electrolyte, can solve problems such as poor chemical properties, and achieve the effect of simple operation and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

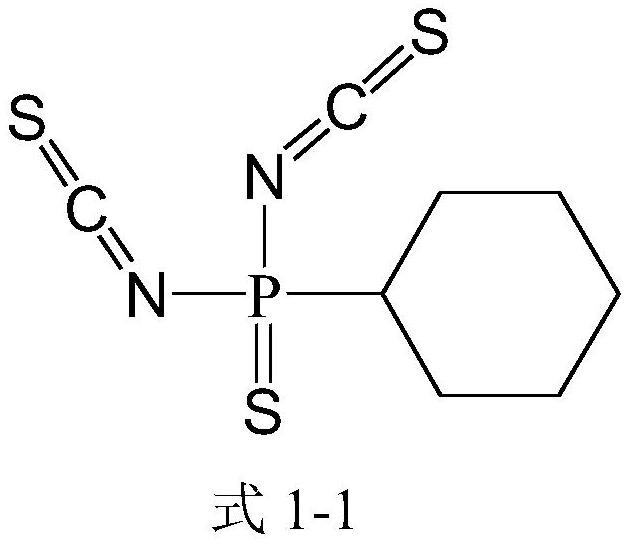

[0055] (1) In-situ curing electrolyte configuration: mix 300g of EC, 600g of EMC, and 100g of DEC in a glove box with a water content of less than 1ppm and an oxygen content of less than 2ppm, and then add 150g of LiPF 6 The basic electrolyte was obtained; 25g NCS-1 and 30g PVA-CN-1 (Mw=3000) were added to the basic electrolyte to obtain in-situ solidified electrolyte E1; wherein, the composition of E1 was shown in Table 1.

[0056] (2) Assembly and production of dry cells: mix the positive electrode material Ni83, carbon black, CNT, and PVDF in a ratio of 100:0.6:0.6:1.5, coat them on a 12 μm aluminum foil, and then dry them at 85°C; Graphite, carbon black, SBR, and CMC were evenly mixed and coated on an 8μm copper foil in a ratio of 100:0.9:1.9:1.5, and then dried at 90°C; using a ceramic diaphragm as a diaphragm, the positive and negative electrodes were rolled The winding form is made into a dry cell.

[0057] (3) Formation, aging and capacity separation process: Inject t...

Embodiment 2-17

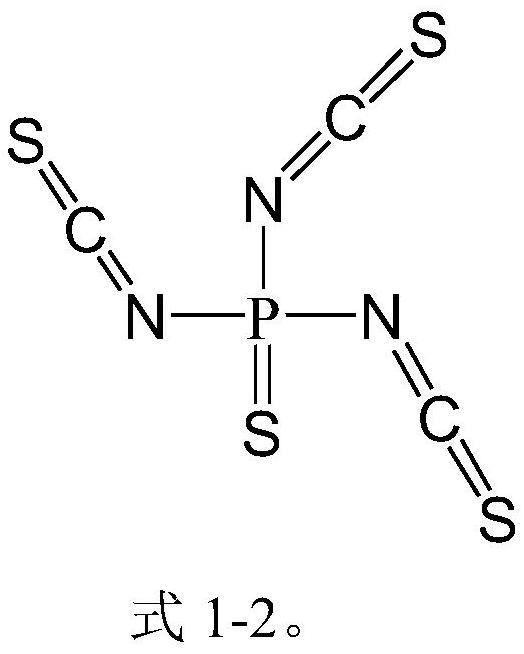

[0059] Prepare in-situ solidified electrolyte E2-E17 and gel lithium-ion battery C2-C17 according to the method described in Example 1, the difference is that the solvent and lithium salt and the addition amount are kept constant, and the electropolymerization monomer and crosslinking agent are changed , the compositions of the obtained in-situ solidified electrolytes E2-E17 are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com