Woven fabric inspection apparatus for loom

A technology for inspection devices and fabrics, which is applied to measuring devices, auxiliary equipment for weaving, textiles, etc., can solve the problems of high production costs, poor operation efficiency, and time-consuming loading and unloading operations, and achieve the effects of simple loading and unloading and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

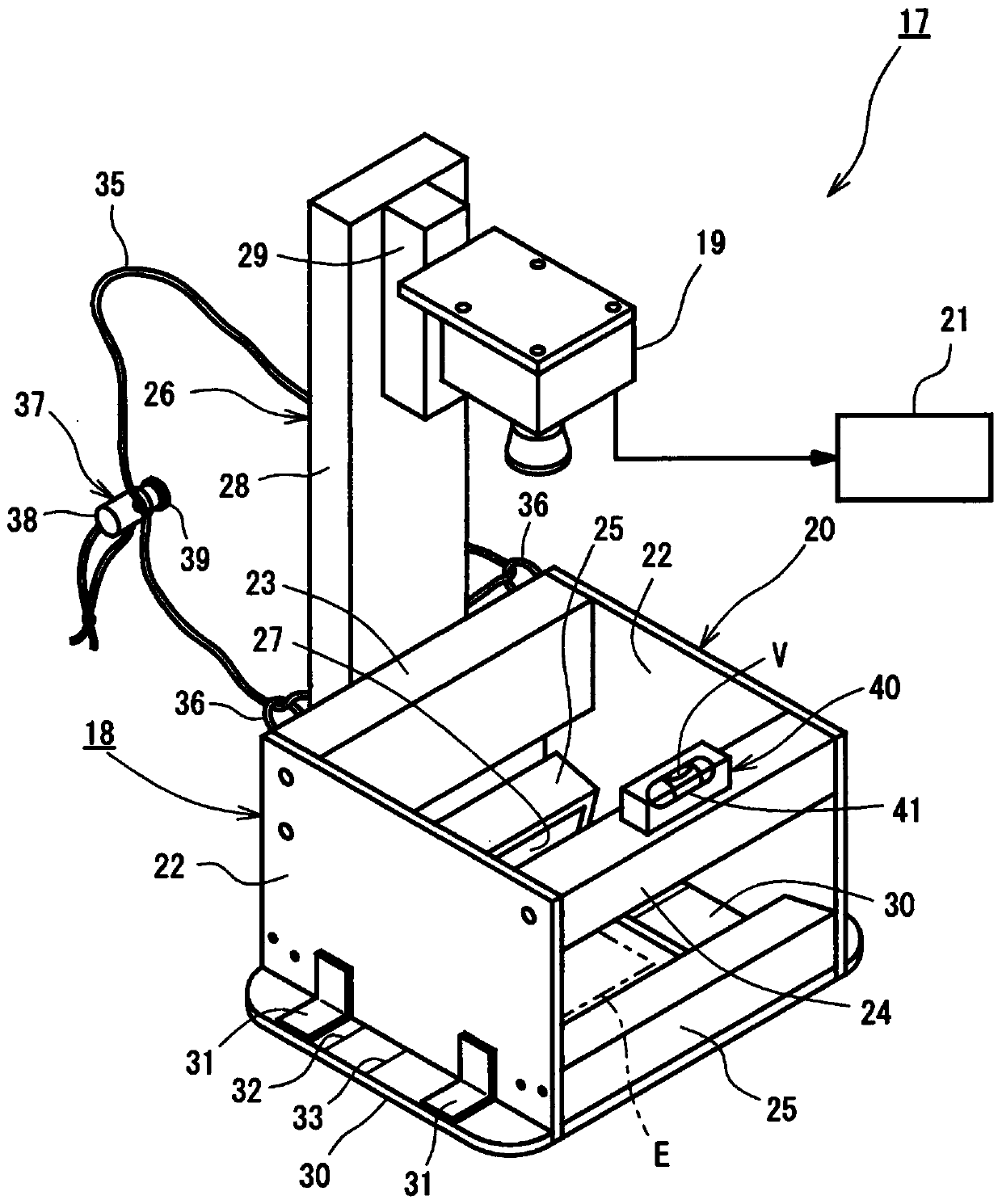

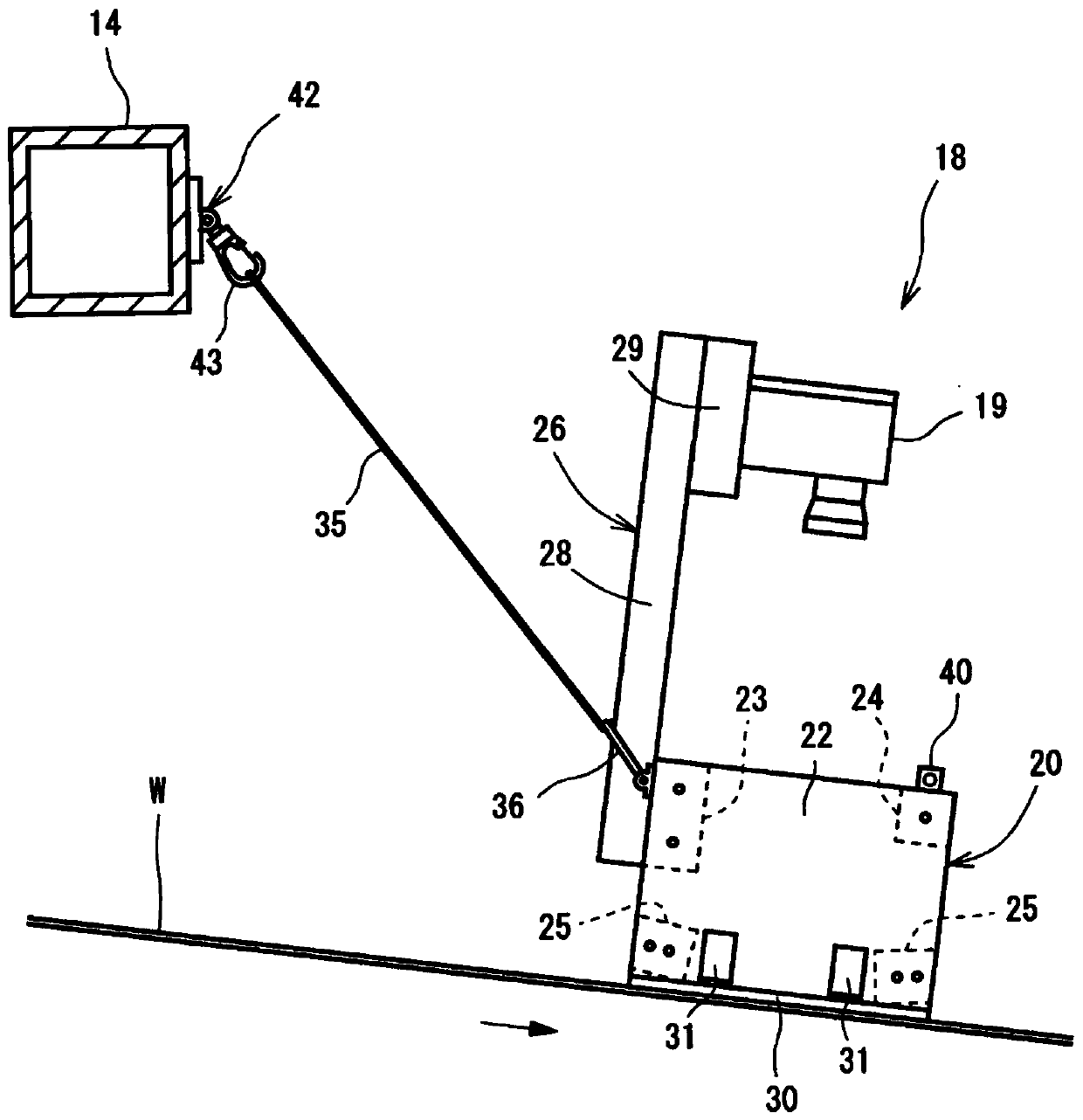

[0021] Hereinafter, a fabric inspection device for a loom according to an embodiment of the present invention will be described with reference to the drawings. First, the loom according to the present embodiment will be described, but the loom of the present embodiment is an air-jet loom. The fabric inspection device of the loom according to the present embodiment is used to detect the presence or absence of a weave defect in the fabric.

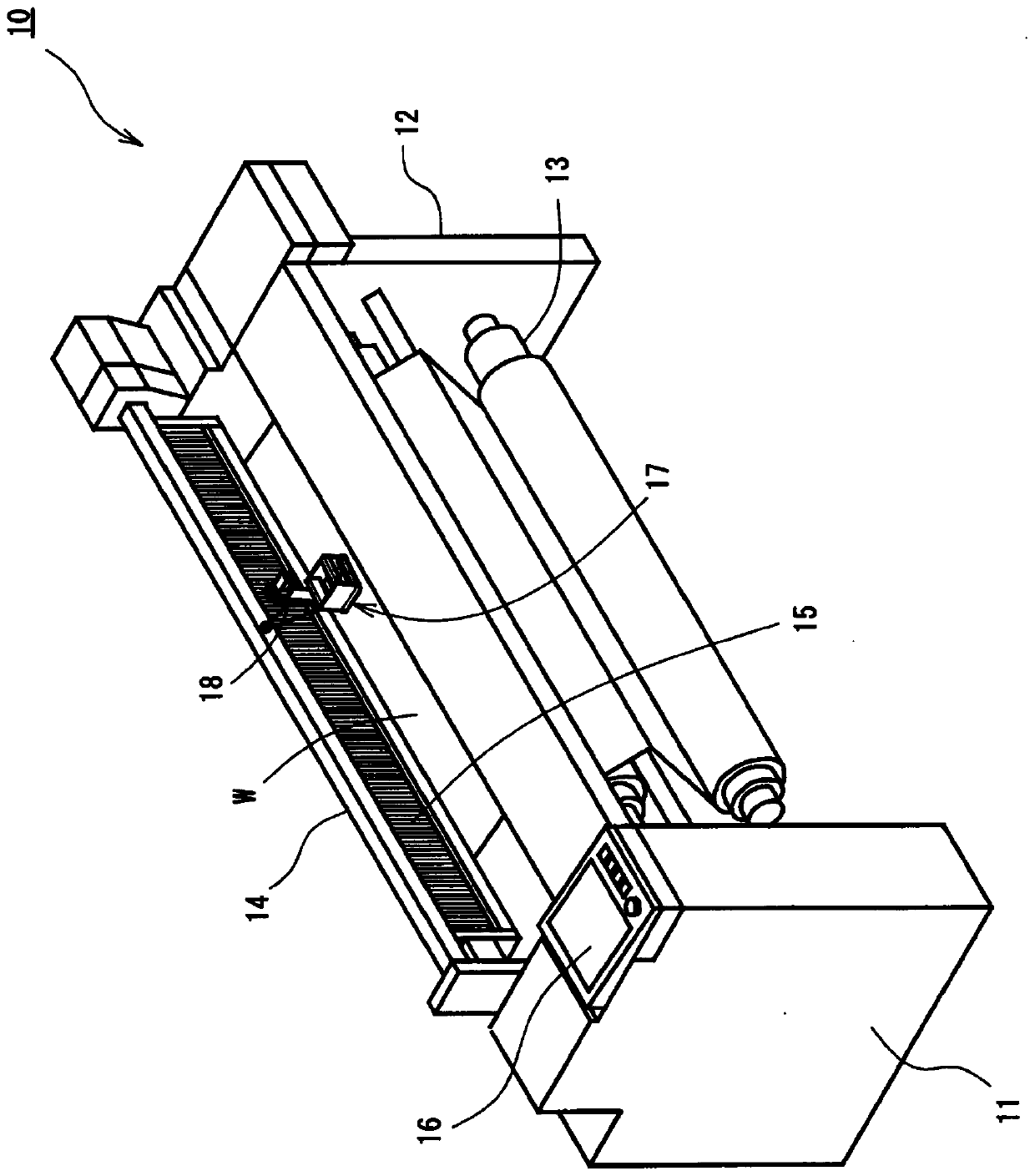

[0022] like figure 1 As shown, the air jet loom 10 includes a pair of left and right side frames 11 , 12 . The pair of left and right side frames 11 and 12 are connected by a plurality of horizontal rails (not shown). The air-jet loom 10 includes a warp beam (not shown) around which a warp yarn is wound, and a cloth take-up roll 13 around which a woven fabric W is wound. The warp beam constitutes a part of a feeding device that feeds out the warp yarn, and the fabric winding roller 13 constitutes a part of a winding device that winds the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com