Low permeability oil reservoir polymer injectivity evaluation method

A technology of injection ability and evaluation method, which is applied in the field of polymer injection ability evaluation of low permeability reservoirs, can solve the problem of not considering polymer injection ability, etc., and achieves the effect of good shear resistance, good application prospect and good viscosity increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0064] The first embodiment of the present invention relates to a method for evaluating the injection capability of polymers in low-permeability reservoirs, comprising the following steps:

[0065] S1 Construction polymer injection ability evaluation index

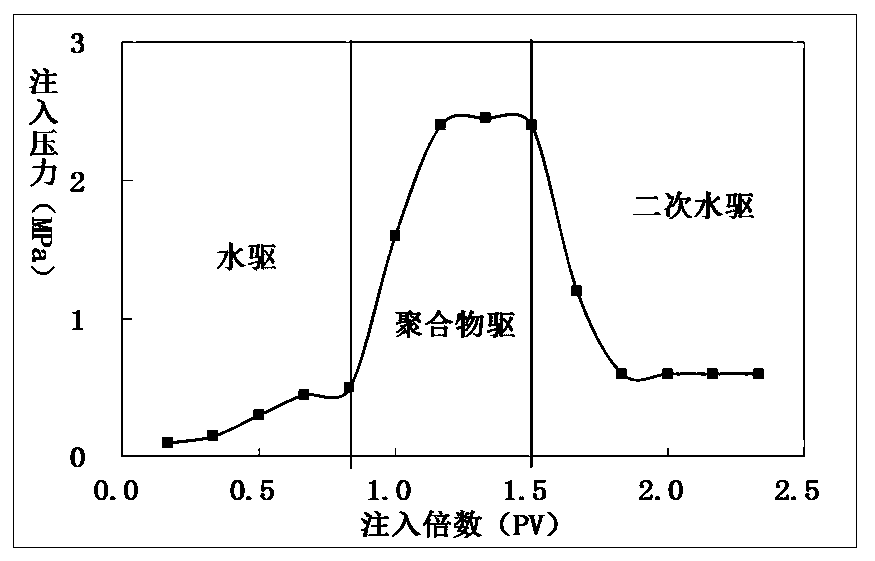

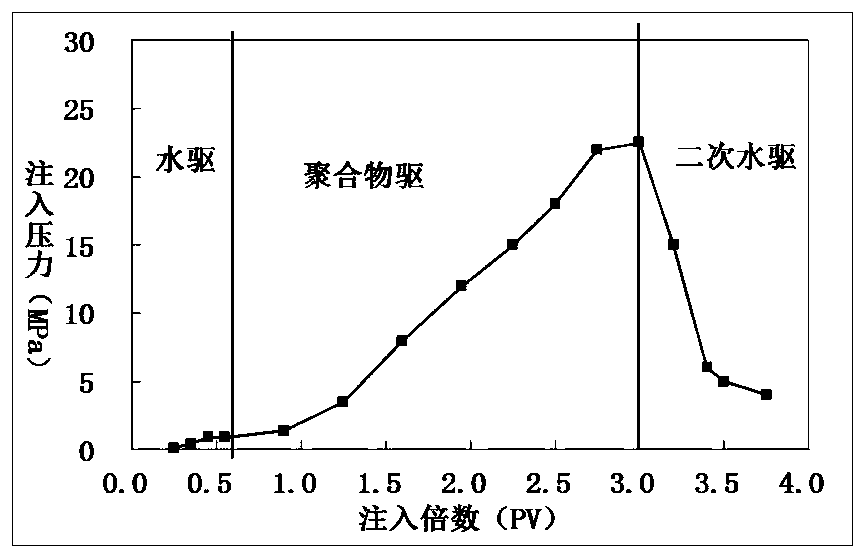

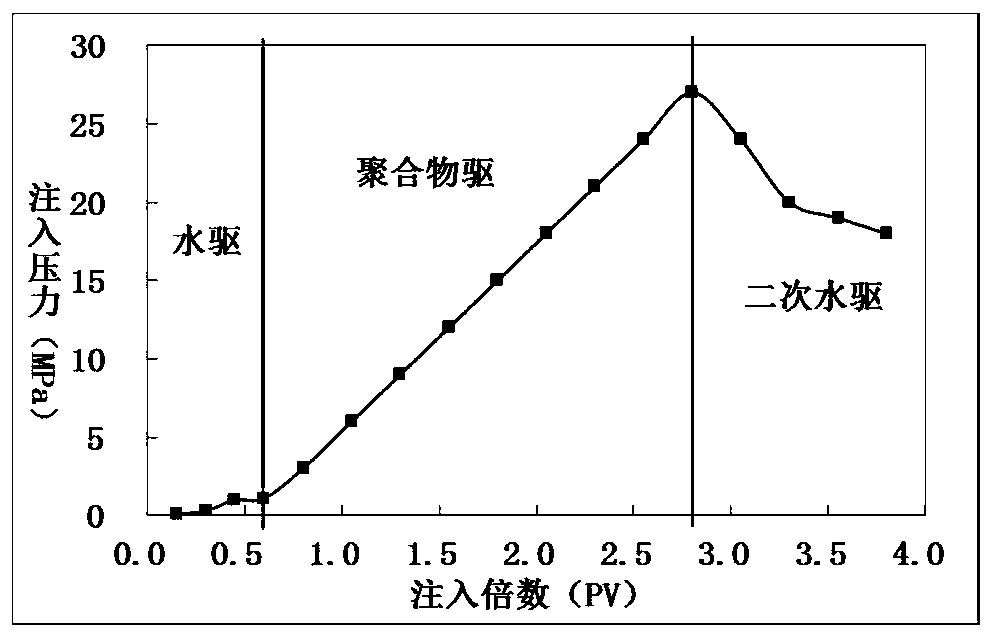

[0066] Through the physical simulation experiment of polymer injection in low-permeability reservoirs, the corresponding evaluation indexes of polymer injection capability in low-permeability reservoirs are constructed, including polymer injection pressure, viscosity retention rate, drag coefficient, residual drag coefficient, plugging capacity and injection curve feature;

[0067] S2 classifies each evaluation index

[0068] According to the results of the polymer injection physical simulation experiment in step S1, combined with the actual reservoir development, the classification basis for each evaluation index described in step S1 is determined one by one, and each evaluation index is divided into one type, two types ...

no. 2 approach

[0077] On the basis of the above embodiments, it should be noted that in the step S2, the basis for the classification of the polymer injection pressure is as follows: according to the requirements of reservoir development, the polymer injection pressure P cannot exceed 90% of the formation fracture pressure, preferably at 60% or less, so 60% and 90% of the maximum allowable pressure (that is, the formation fracture pressure) are used as the cut-off point of the polymer injection pressure, and the polymer injection pressure ≤ 60% of the maximum allowable pressure is divided into one category; 60% of the maximum allowable pressure %90% of the maximum allowable pressure is divided into three categories.

[0078] Further, the viscosity retention rate η is the ratio of the viscosity of the produced liquid to the viscosity of the formulated polymer solution when the injection pressure is stable. A high retention rate proves that polymer molecules can effectively pass through pores a...

no. 3 approach

[0089] On the basis of the above embodiment, further, in the step S3, the weight of each evaluation index is determined, and the gray correlation method is used to process the data, and the processing process is as follows:

[0090] Step 1: Determine the reference sequence and compare the sequence

[0091] Taking each group of cores to improve oil displacement efficiency range as a reference sequence, taking polymer injection pressure, viscosity retention rate, residual resistance coefficient, injection curve characteristics, plugging capacity and resistance coefficient as a comparison sequence;

[0092] Step 2: Dimensionless data processing

[0093] let x 0 ={x 0 (k)|k=1, 2,..., m} is the reference sequence, x i ={x i (k)|k=1, 2,..., m} (i=1, 2,..., n) is a comparison sequence; due to the different dimensions of each parameter, in order to make it comparable, the formula is used for each term Parameters are dimensionless:

[0094] x i (k)'=[x i (k)-min x i (k)] / [max ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com