Material collecting device for drying and crushing equipment

A crushing equipment and collection device technology, which is applied in the field of material collection devices for dry crushing equipment, can solve the problems of poor dust-proof effect, difficulty in moving, time-consuming and labor-intensive, etc., and achieves easy to move and carry, good dust-proof function, and guaranteed stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

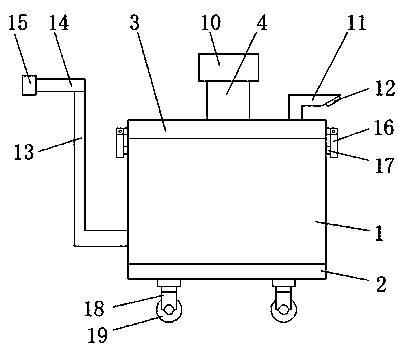

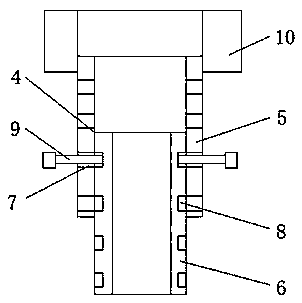

[0022] Reference Figure 1-3 , A material collection device for drying and crushing equipment, comprising a collection bucket 1. The lower surface of the collection bucket 1 is fixedly connected with a base 2, and the upper surface of the collection bucket 1 is fixedly installed with a dust-proof bucket cover 3, and the upper surface of the dust-proof bucket cover 3 A height adjustment mechanism 4 and a dust-proof pressure discharge pipe 11 are installed on the surface. The height adjustment mechanism 4 includes a fixed pipe 6 fixedly connected to the dust-proof bucket cover 3, and the top of the fixed pipe 6 is movably sleeved with a movable sleeve 5 and a movable sleeve 5 Both vertical inner surfaces of the two sides are provided with insertion holes 7, and both vertical outer walls of the fixed pipe 6 are provided with a card slot 8. The insertion pin 9 and a height adjustment mechanism 4 are inserted into the insertion hole 7 and the card slot 8. A threaded connection pipe 1...

Embodiment 2

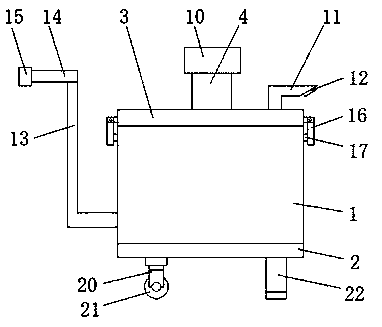

[0028] Reference Figure 2-3 , A material collection device for drying and crushing equipment, comprising a collection bucket 1, a base 2 is fixedly connected to the lower surface of the collection bucket 1, a dust-proof bucket cover 3 is fixedly installed on the upper surface of the collection bucket 1, and the upper surface of the dust-proof bucket cover 3 A height adjustment mechanism 4 and a dust-proof pressure discharge pipe 11 are installed on the surface. The height adjustment mechanism 4 includes a fixed pipe 6 fixedly connected to the dust-proof bucket cover 3, and the top of the fixed pipe 6 is movably sleeved with a movable sleeve 5 and a movable sleeve 5 Both vertical inner surfaces of the two sides are provided with insertion holes 7, and both vertical outer walls of the fixed pipe 6 are provided with a card slot 8. The insertion pin 9 and a height adjustment mechanism 4 are inserted into the insertion hole 7 and the card slot 8. A threaded connection pipe 10 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com