High-performance aluminum alloy engine cylinder head and casting method thereof

An engine cylinder head, aluminum alloy technology, applied in engine components, machines/engines, cylinder heads, etc., can solve the problems of poor casting performance, long slag processing process, insufficient mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

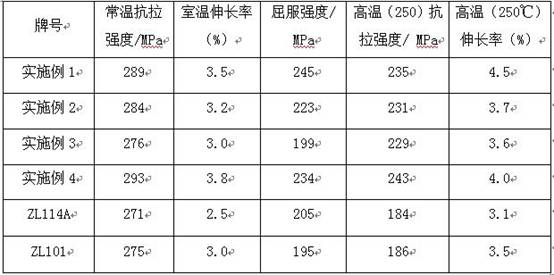

Examples

Embodiment 1

[0025] The chemical composition of the high-performance aluminum alloy engine cylinder head is as follows by mass percentage:

[0026] Si:8.0%, Ni:2.0%, Cu:0.5%, Mg:0.3%, Zn:0.2%, Zr:0.1%, Sc:0.1%, La:0.1%, Sb:0.1%, Mn≤0.3%, Fe≤0.2%, Ti≤0.2%, individual content of other impurity elements≤0.05%, total content of other impurity elements≤0.15%, and the balance is Al.

[0027] Its casting method is:

[0028] (1) Smelting: first put aluminum ingots and high-purity silicon into the melting furnace according to the formula ratio, and then add other alloy components in turn for alloying. After complete melting, carry out on-line degassing and slag removal treatment on the aluminum alloy melt to obtain aluminum alloy solution;

[0029] The online degassing is degassing by using argon and chlorine mixed gas, the flow rate is 0.2m 3 / h, the flow ratio of argon and chlorine is 1:0.4, the partial pressure is 0.10MPa, and the rotor speed is 400rpm / min.

[0030] (2) Modification treatmen...

Embodiment 2

[0039] The chemical composition of the high-performance aluminum alloy engine cylinder head is as follows by mass percentage:

[0040] Si:8.5%, Ni:3.0%, Cu:1.8%, Mg:0.8%, Zn:0.4%, Zr:0.25%, Sc:0.15%, La:0.18%, Sb:0.18%, Mn≤0.3%, Fe≤0.2%, Ti≤0.2%, individual content of other impurity elements≤0.05%, total content of other impurity elements≤0.15%, and the balance is Al.

[0041] Its casting method is:

[0042] (1) Smelting: first put aluminum ingots and high-purity silicon into the melting furnace according to the formula ratio, and then add other alloy components in turn for alloying. After complete melting, carry out on-line degassing and slag removal treatment on the aluminum alloy melt to obtain aluminum alloy solution;

[0043] The online degassing is degassing by using argon and chlorine mixed gas with a flow rate of 0.3 m 3 / h, the flow ratio of argon and chlorine is 1:0.4, the partial pressure is 0.2MPa, and the rotor speed is 450rpm / min.

[0044] (2) Modification tr...

Embodiment 3

[0052] The chemical composition of the high-performance aluminum alloy engine cylinder head is as follows by mass percentage:

[0053] Si: 9.5%, Ni: 3.5%, Cu: 2.0%, Mg: 1.0%, Zn: 0.5%, Zr: 0.3%, Sc: 0.25%, La: 0.2%, Sb: 0.2%, Mn≤0.3%, Fe≤0.2%, Ti≤0.2%, individual content of other impurity elements≤0.05%, total content of other impurity elements≤0.15%, and the balance is Al.

[0054] Its casting method is:

[0055] (1) Smelting: first put aluminum ingots and high-purity silicon into the melting furnace according to the formula ratio, and then add other alloy components in turn for alloying. After complete melting, carry out on-line degassing and slag removal treatment on the aluminum alloy melt to obtain aluminum alloy solution;

[0056] The online degassing is degassing by using argon and chlorine mixed gas, the flow rate is 0.4m 3 / h, the flow ratio of argon and chlorine is 1:0.4, the partial pressure is 0.40MPa, and the rotor speed is 500rpm / min.

[0057] (2) Modificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com