Method for preventing existing tunnel from floating in unloading earthwork process directly above tunnel

A technology directly above the existing tunnel, which is applied in the direction of foundation structure engineering, sheet pile walls, protective devices, etc., can solve the problems of existing tunnels such as floating, achieve the effect of strengthening the soil, improving stability, and simple construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

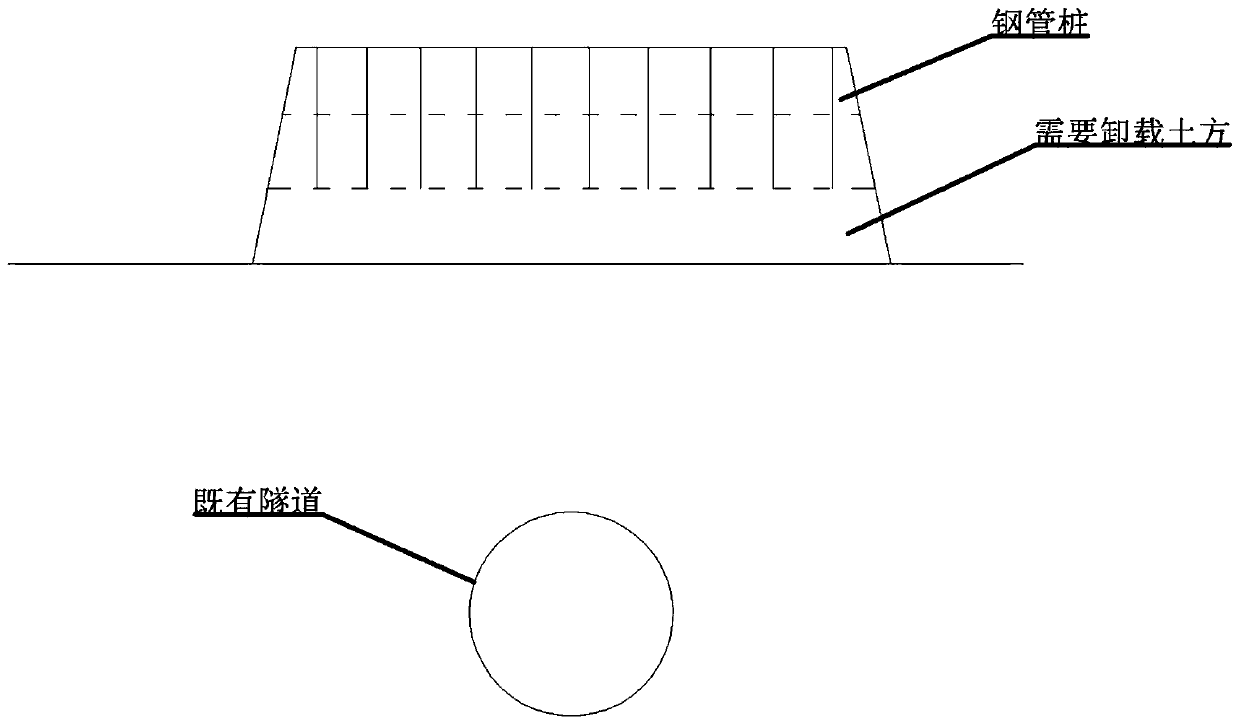

[0033] In this embodiment, a method for preventing the existing tunnel from floating up during unloading of earthwork directly above it is provided.

[0034] This embodiment is aimed at removing the soil mound on the surface directly above the tunnel to avoid weathering of the soil mound and raising dust, and at the same time construct other buildings on the surface to beautify the urban environment.

[0035] The method includes the following steps:

[0036] Step 1. Determine the range and depth of earthwork that needs to be unloaded right above the existing tunnel;

[0037] In this embodiment, first confirm the range and thickness of the earthwork directly above the tunnel in the mound, that is, confirm the range that can affect the uplift of the tunnel;

[0038] Step 2, divide the earthwork that needs to be unloaded into multiple unloading layers from top to bottom;

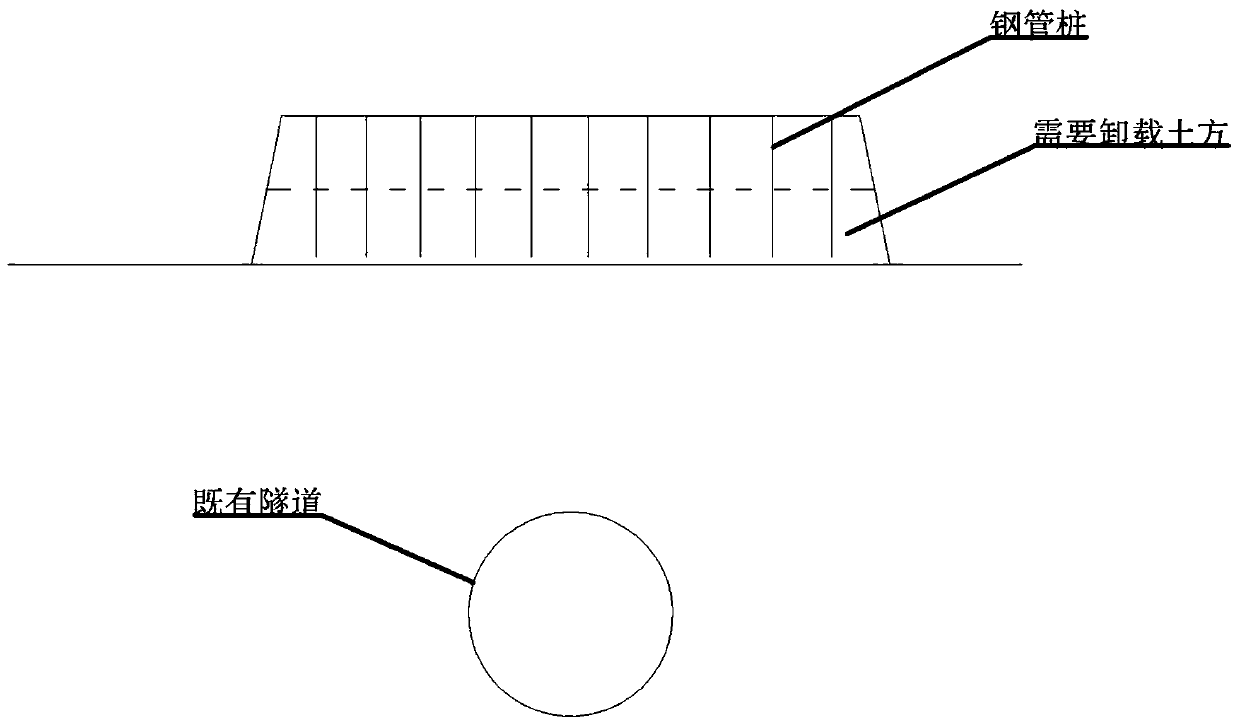

[0039] In this embodiment, after confirming the scope of the soil mound that can affect the floating of th...

Embodiment 2

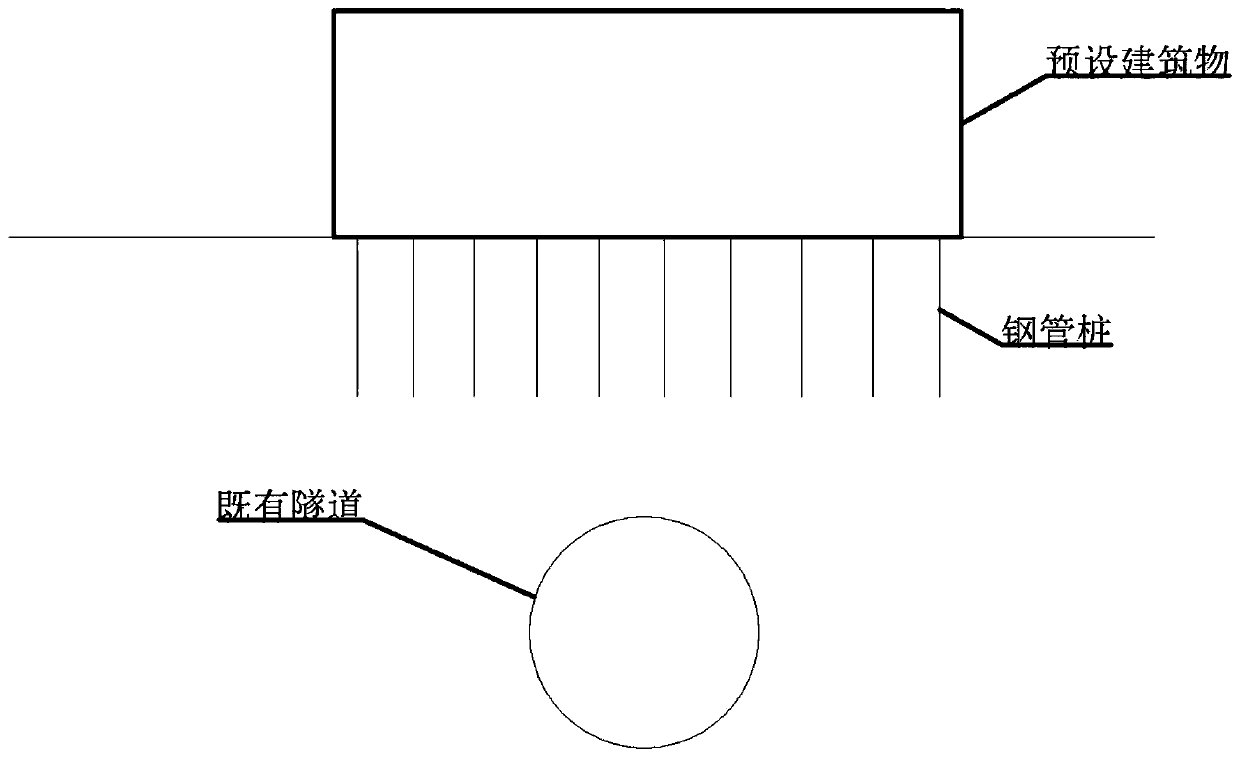

[0051] This embodiment is aimed at excavating the foundation pit downwards at the surface directly above the existing tunnel, and constructing the corresponding buildings, that is, the soil with a certain thickness between the surface and the existing tunnel is removed, and then the existing There is a certain amount of unloading in the tunnel. Therefore, in order to prevent the existing tunnel from floating up during the unloading process, this embodiment is implemented according to the following method.

[0052] The method includes the following steps:

[0053] Step 1. Determine the range and depth of earthwork that needs to be unloaded right above the existing tunnel;

[0054]In this embodiment, first confirm the range and thickness of the earthwork directly above the tunnel in the foundation pit, that is, confirm the range that can affect the buoyancy of the tunnel;

[0055] Step 2, divide the earthwork that needs to be unloaded into multiple unloading layers from top to ...

Embodiment 3

[0068] In this embodiment, the construction object is a combination of the earthwork on the corresponding surface directly above the existing tunnel and the earthwork corresponding to the excavation of the foundation pit directly above the existing tunnel.

[0069] The construction method is the combination of Embodiments 1 and 2, that is, the processed soil is the earthwork corresponding to the earthwork on the surface and the foundation pit, and the rest are the same.

[0070] Further, in Examples 1-3, in order to save the material of steel pipe piles and reduce the damage to the original soil, the steel pipe piles are specifically composed of steel pipes of two lengths, and the two kinds of steel pipes are pressed at intervals. into the corresponding unloading layer.

[0071] Through the above-mentioned arrangement, the steel pipe piles are arranged in a staggered manner, and while saving costs, the soil body can be effectively reinforced to prevent the above and further pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com