Wood floor laying robot

A wooden floor and robot technology, applied in construction, building construction, etc., can solve the problems of differences in installation experience and installation methods of workers, auxiliary tools make the construction site messy, and it is difficult to protect finished products, so as to improve laying efficiency, Save labor costs and ensure fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

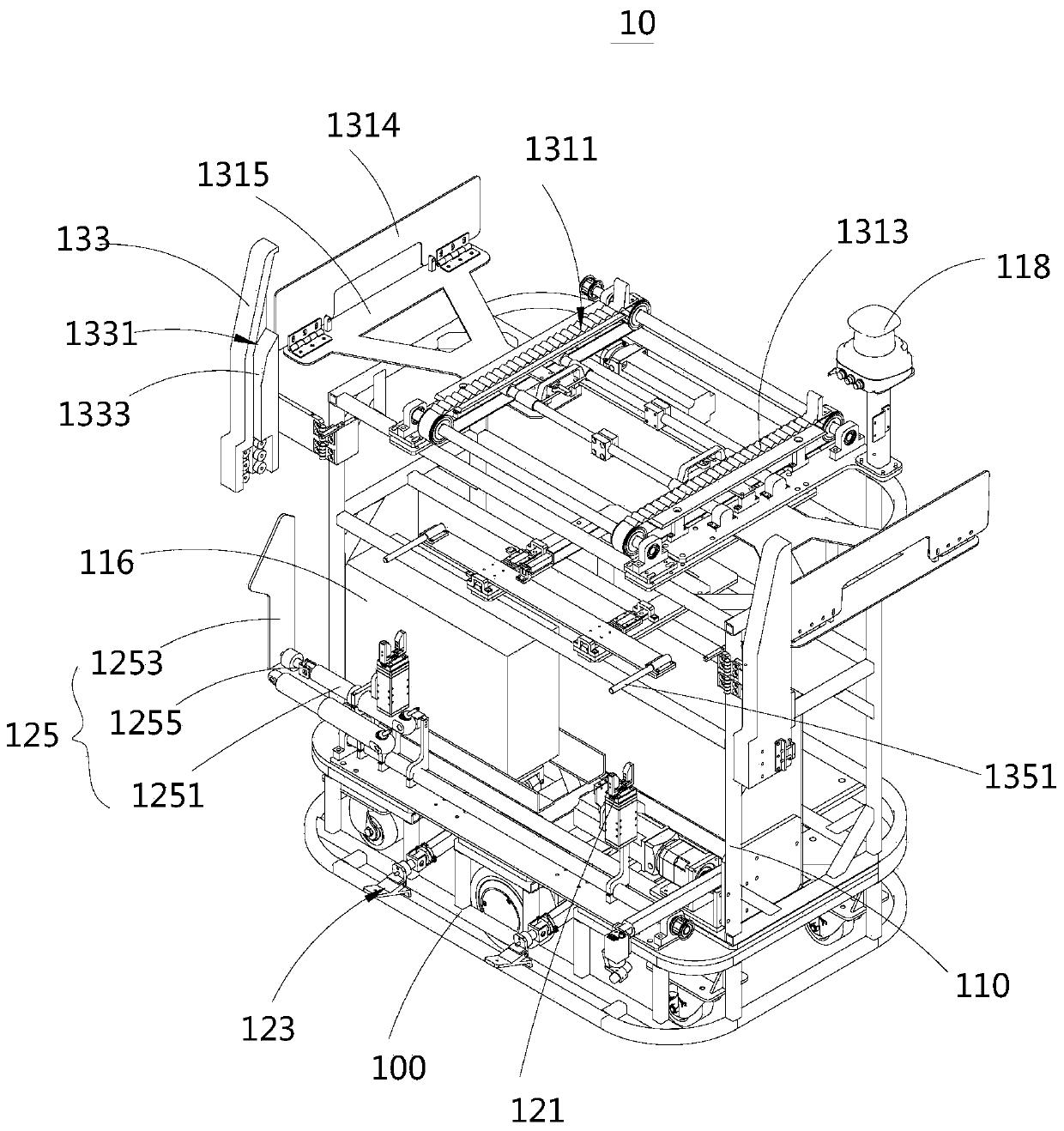

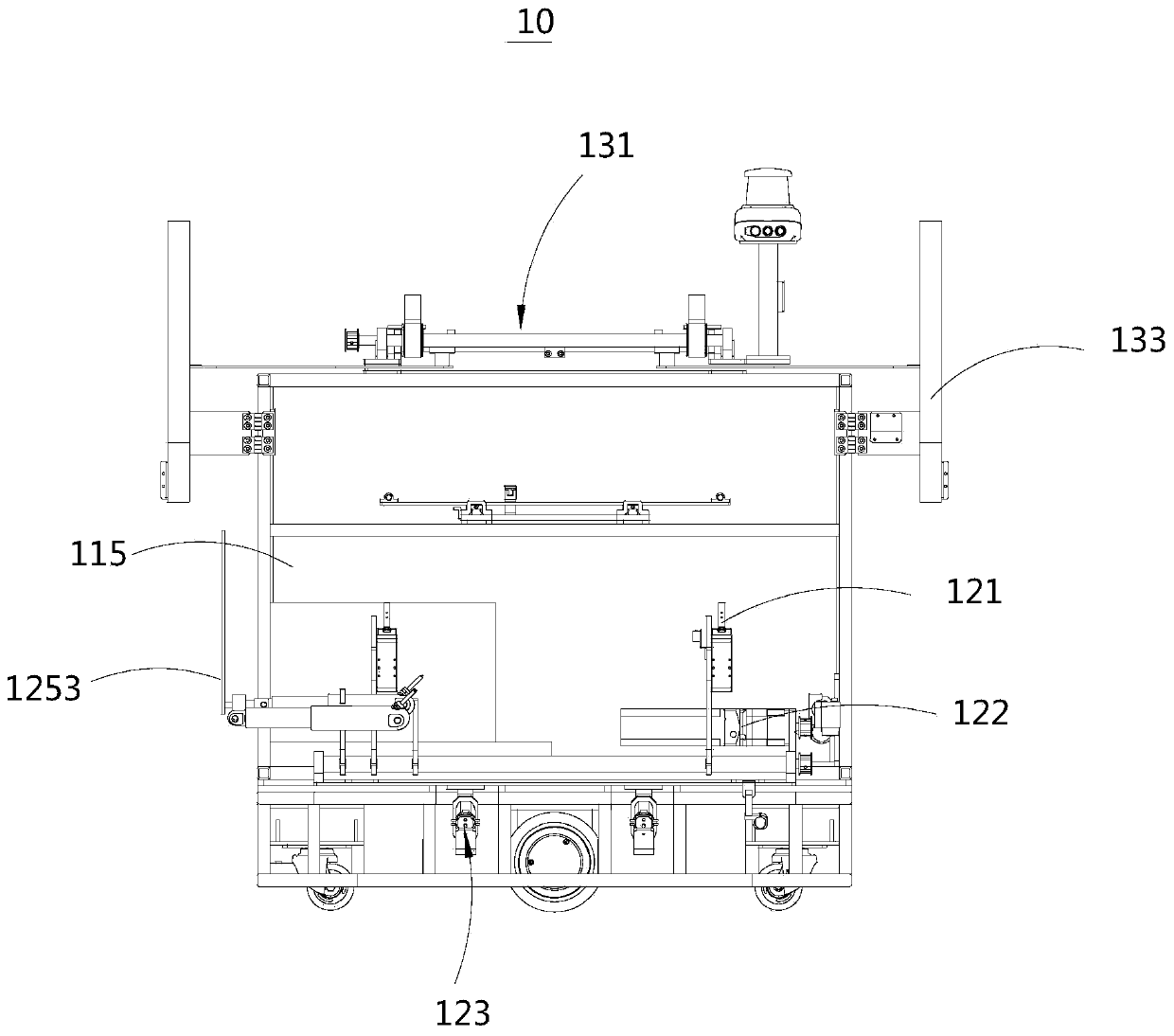

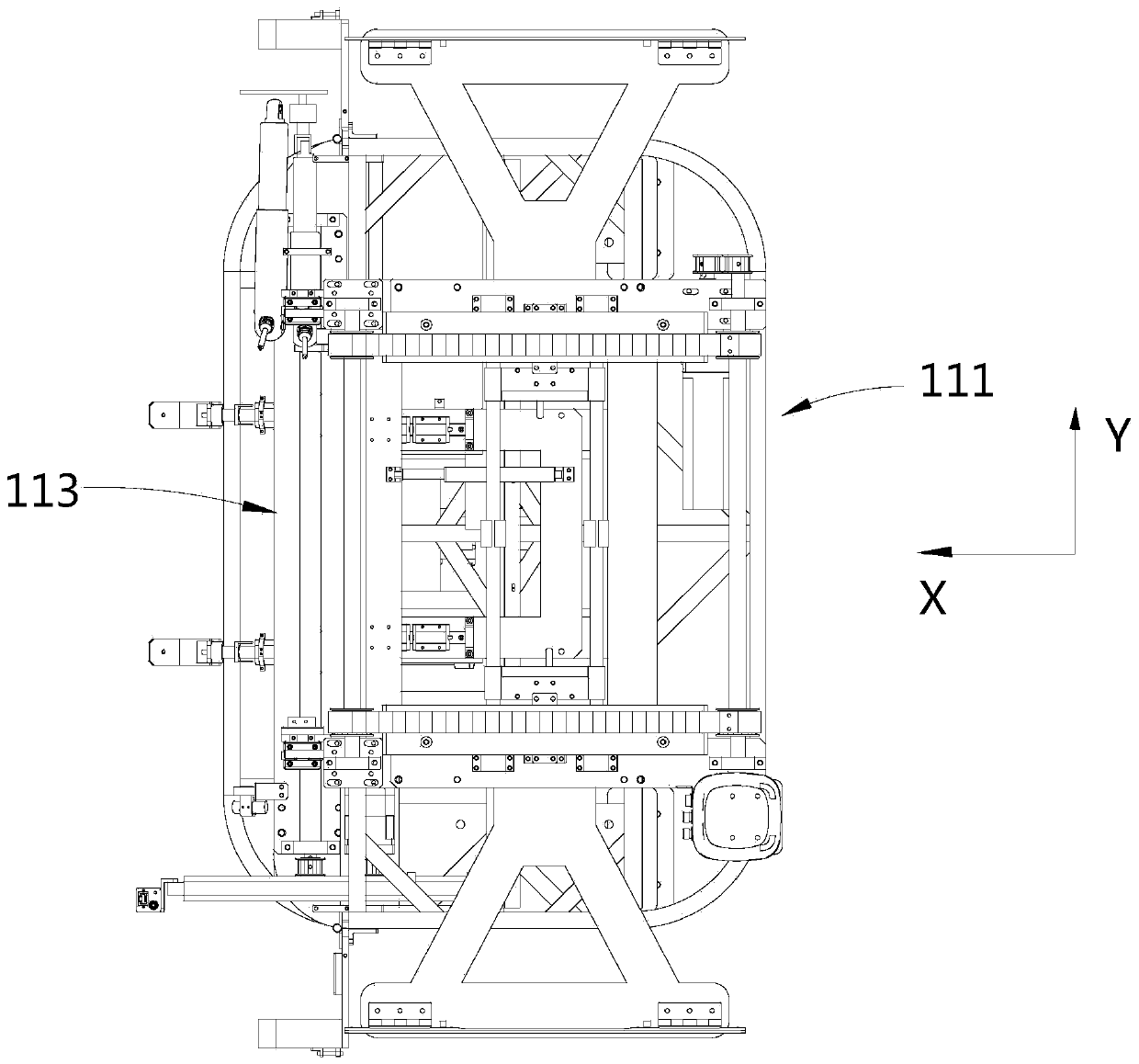

[0042] Please refer to figure 1 , 2 , 3 and Figure 4 , The wooden floor laying robot 10 provided in this application mainly includes a chassis 100, a frame 110, a silo, a blanking mechanism, and a paving mechanism.

[0043] Specifically, the chassis 100 is arranged at the bottom of the rack 110 to make the wooden floor laying robot 10 move in the third preset direction.

[0044] Wherein, the way of moving in the third preset direction can be manually pushed, but in order to save manpower, the chassis 100 can also be automated. For example, the chassis 100 is an AGV (unmanned guided vehicle) trolley, which can make the wood floor laying robot 10 follow The third preset direction automatically moves.

[0045] The projection of the chassis 100 on the horizontal plane is rectangular, and the third preset direction and the width direction of the projection of the chassis 100 on the horizontal plane may be parallel or perpendicular, or intersect, which is not limited herein.

[0046] Optio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com