Air fan automatic oil filling device and air fan

An automatic oil injection and fan technology, which is applied to machines/engines, components of pumping devices for elastic fluids, mechanical equipment, etc., can solve problems such as difficult lubrication of bearings in fans, reduce manual operations, and be widely used. cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

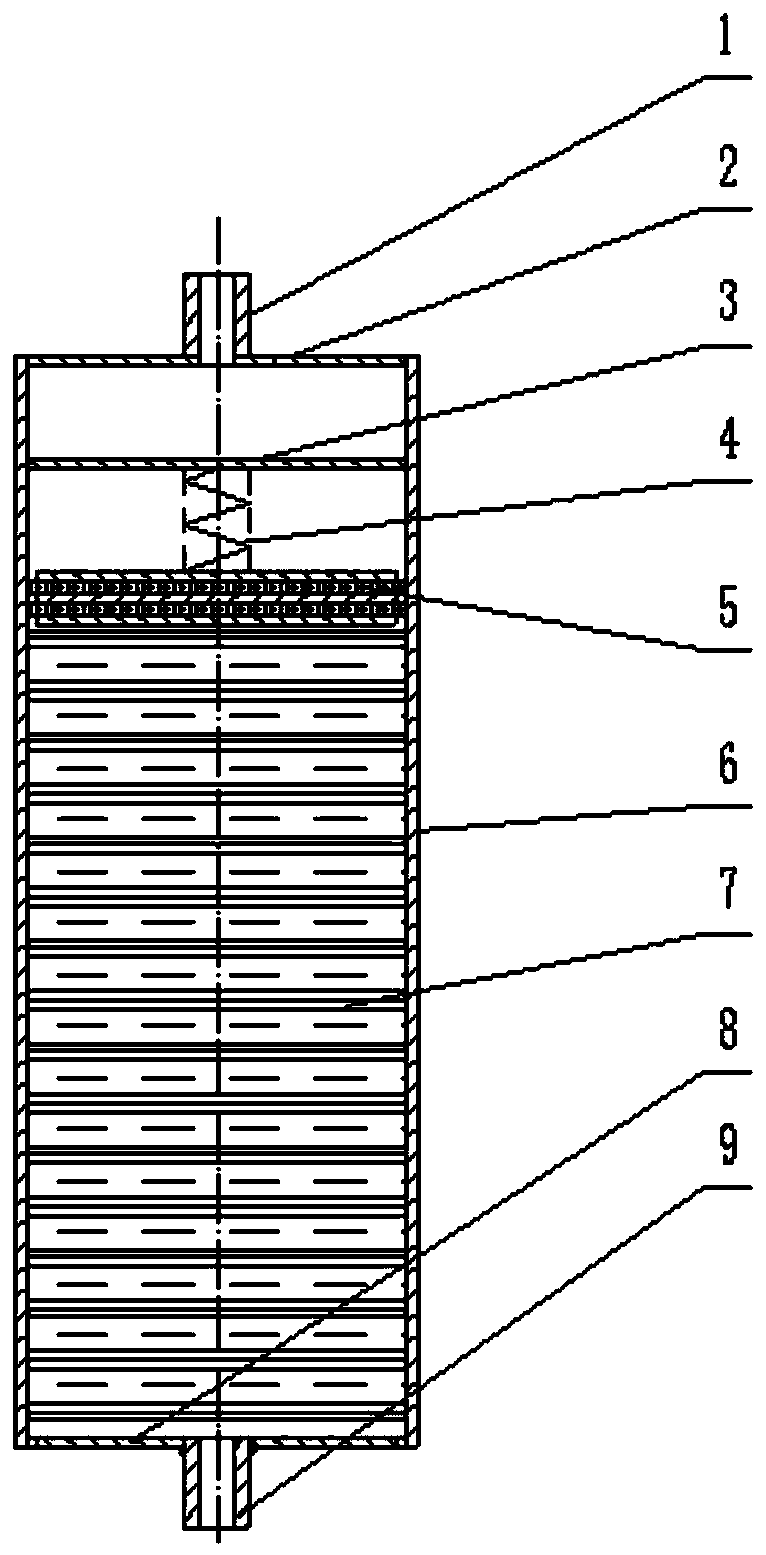

[0026] Such as figure 1 As shown, the present invention provides an automatic oiling device for a fan, which includes an oil storage cylinder 6 with openings at both ends. It communicates with the lubricating place through an oil pipe 11; the oil storage cylinder 6 stores a lubricant 7. It can be seen that the automatic oiling device 100 for the blower fan 15 includes an oil storage cylinder 6 with openings at both ends. The oil pipes 11 communicate with each other; the oil storage cylinder 6 stores a lubricant 7 . During the operation of the fan 15, static pressure is generated on the back of the fan to form a static pressure space on the back of the fan 15, which is connected to the oil storage cylinder 6 through the air pipe 10, and the lubricant 7 is stored in the oil storage cylinder 6. Under the action of pressure, the lubrication Agent 7 is slowly squeezed into the lubricated place. Lubricating place comprises motor 17 bearing 18, and lubricant 7 is generally grease,...

Embodiment 2

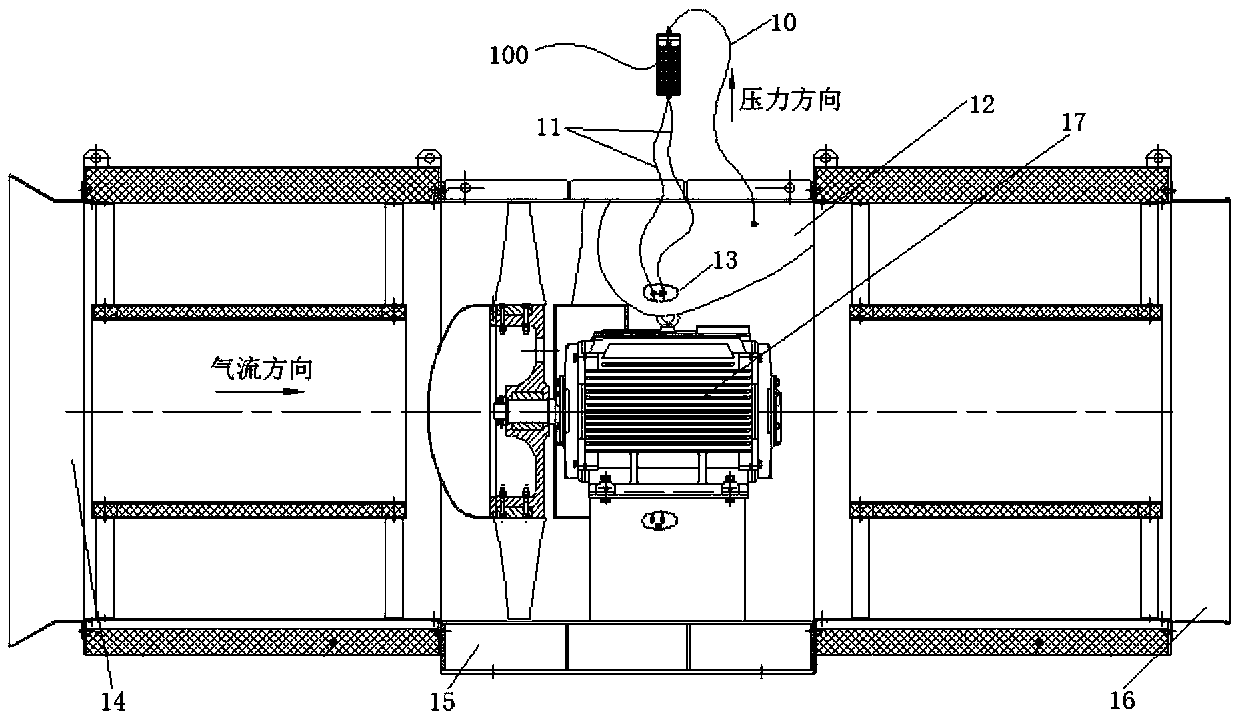

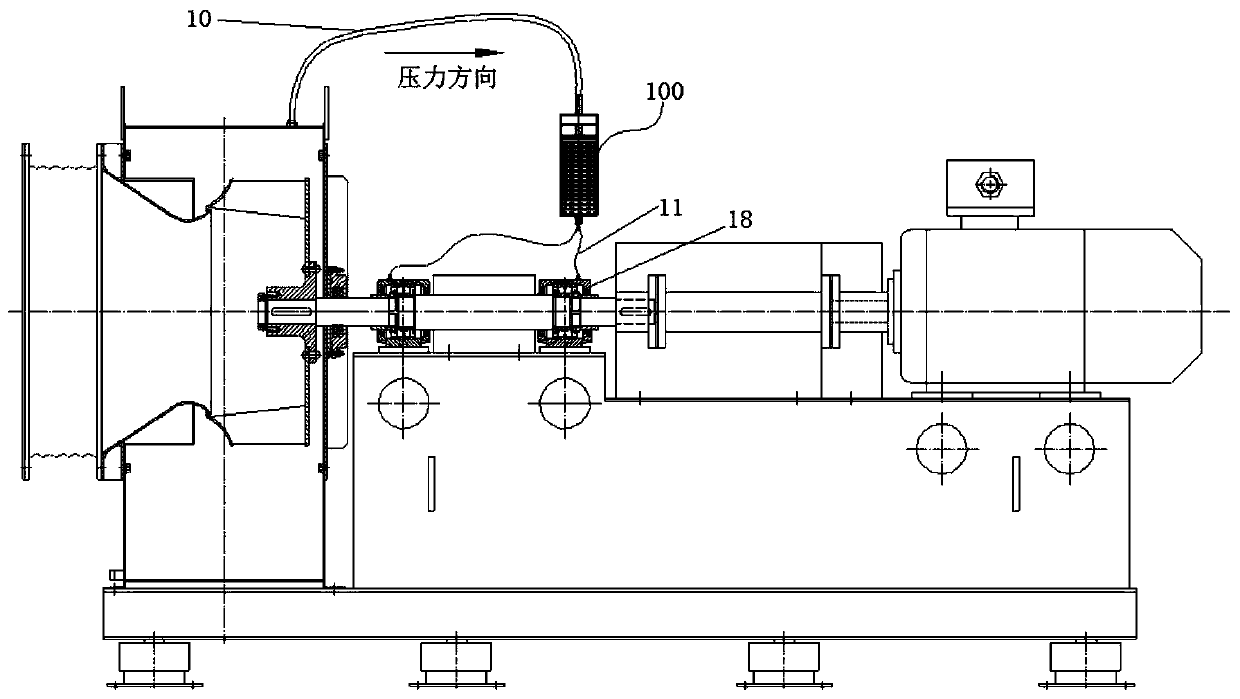

[0035] Such as figure 2 with image 3 As shown, the automatic oiling device 100 is fixedly connected to the casing of the fan 15 , and the automatic oiling device 100 is installed near the static pressure space 12 on the back of the fan, and is located between the air inlet pipe 14 and the air outlet pipe 16 . When the fan 15 is running, it can provide potential energy to the oil injection device, so as to supply oil to the bearing 18 in the motor 17 .

[0036] The specific working principle is as follows Figure 1 to Figure 3 Shown:

[0037] The automatic oiling device 100 is connected to the casing of the fan 15 , and the fan 15 can provide potential energy to be supplied to the oil storage cylinder 6 of the automatic oiling device 100 when it is running. The oil joint 9 of the automatic oiling device 100 is connected to a lubricating point, which can be lubricated at a single point or at multiple points. The intake end of the oil storage cylinder 6 is slidably provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com