Combined splicing type roller shaft brush

A spliced, roller-shaft technology, applied in the field of brushes, can solve the problem that the brush roller cannot replace the bristles separately, and achieve the effect of quick combination and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

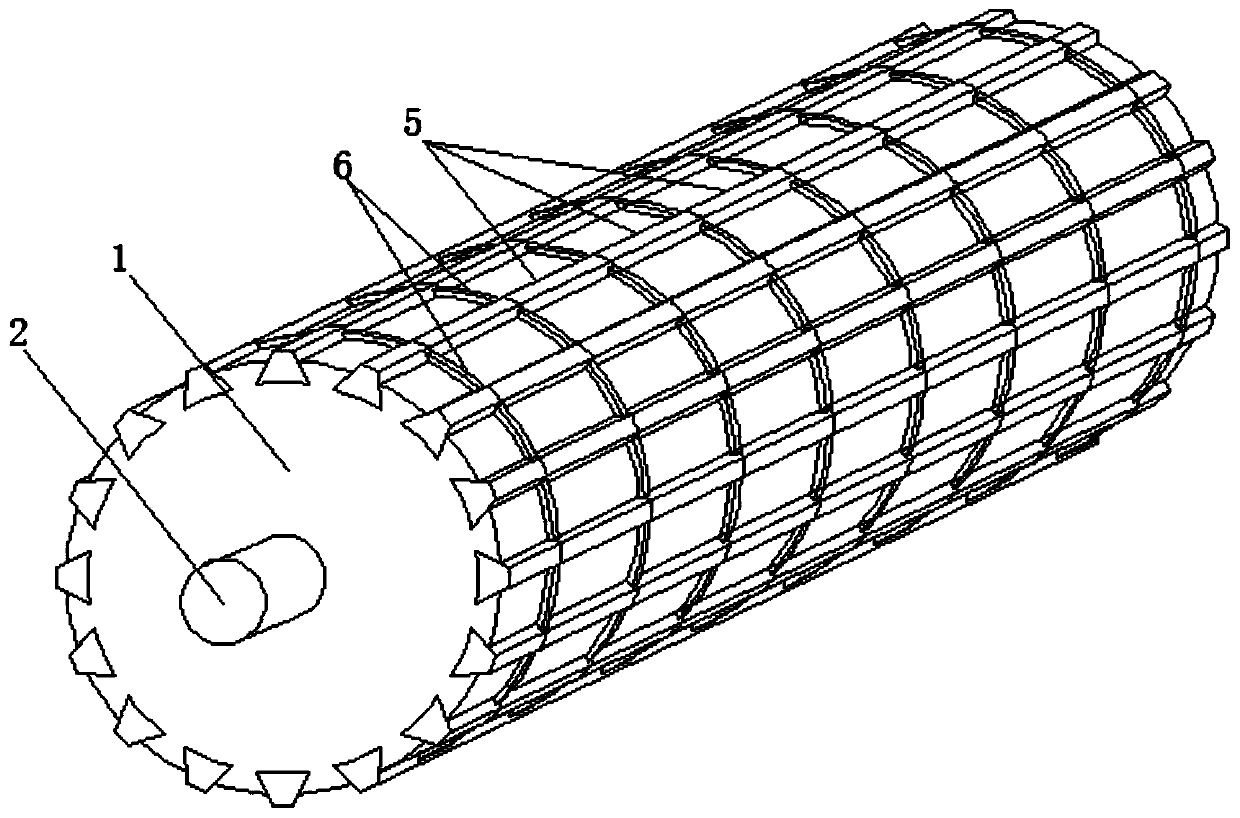

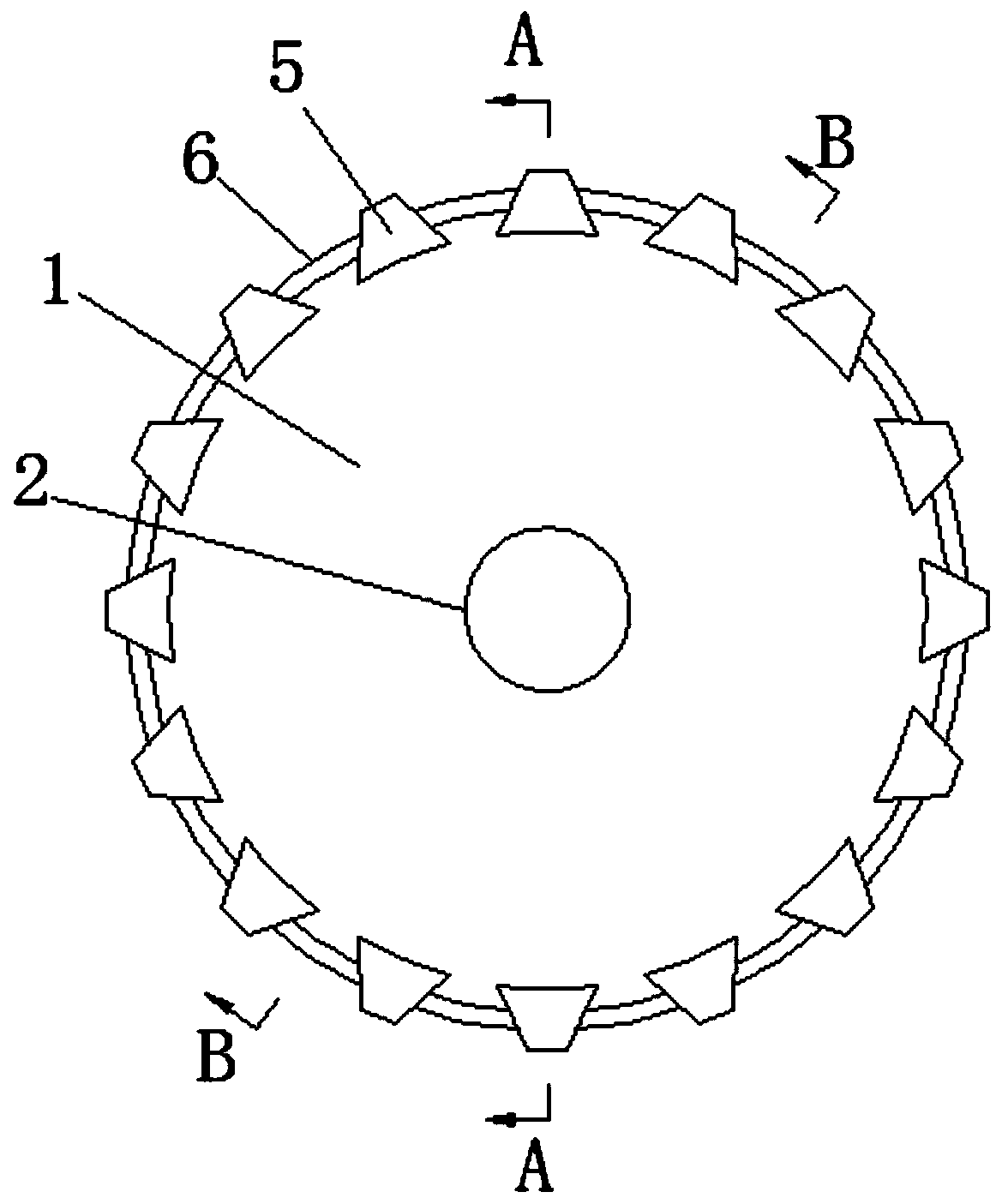

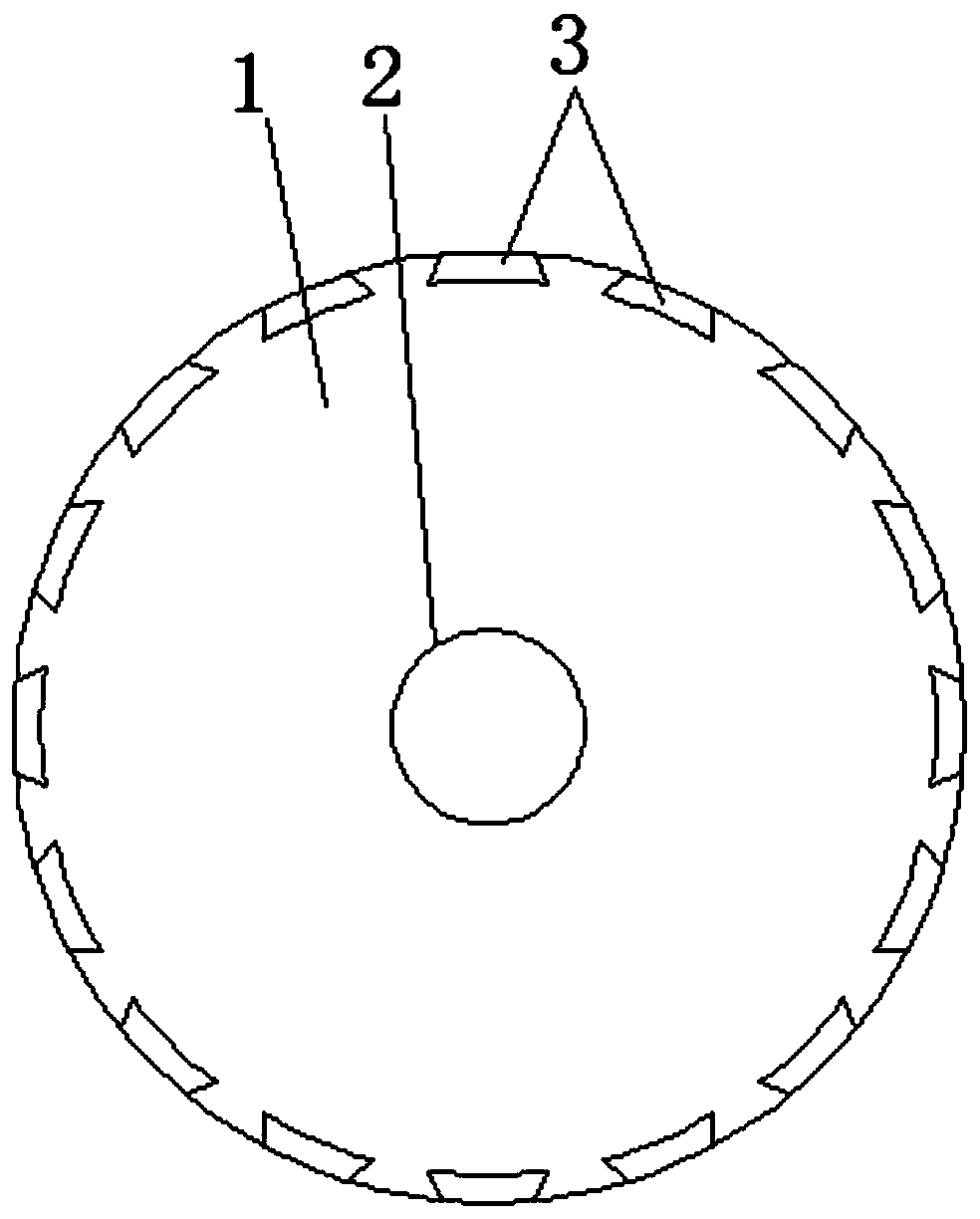

[0023] Such as Figure 1-6 As shown, a combined splicing roller shaft brush includes a roller body 1, a rotating shaft 2 is installed on the roller body 1, and is connected with a power mechanism through the rotating shaft 2, so as to rotate and clean; the circumferential side wall of the roller body 1 is provided with several There are sixteen axial grooves 3 in this embodiment, and the sixteen axial grooves 3 are evenly spaced along the circumferential direction of the roller body 1 .

[0024] The circumferential side wall of the roller body 1 is also provided with several circumferential grooves 4. In this embodiment, there are preferably eight circumferential grooves 4, and the eight circumferential grooves 4 are evenly spaced along the axial direction of the roller body 1;

[0025] In this embodiment, several brush bodies 5 matching the axial grooves 3 are provided in the axial grooves 3 , and bristles (not shown in the figure) are arranged on the brush bodies 5 .

[002...

Embodiment 2

[0031] The difference from Embodiment 1 is that in this embodiment, a first half groove and a second half groove are respectively provided on both ends of the brush body 5, and the first half groove and the second half groove form an arc-shaped through groove. Such arrangement makes the manufacture of the brush body 5 easier under the premise of ensuring that the elastic clip 6 can normally fix the brush body 5 .

Embodiment 3

[0033] The difference from Embodiment 1 is that in this embodiment, the difference between the length of the elastic clip 6 and the circumference of the circumferential groove 4 is greater than the width of the axial groove 3, so that after the elastic clip 6 is installed, it cannot be closed When the notch of the brush is aligned with the axial groove 3, the brush body 5 can not be constrained by it, and can slide in the axial direction; in addition, the difference between the length of the elastic clip 6 and the circumference of the circumferential groove 4 is smaller than that of the axial groove 3, so that when the gap that cannot be closed by the elastic clip 6 is at a certain position (between the two axial grooves 3), all the brush bodies 5 can be fixed.

[0034] When replacing the brush body 5, it is not necessary to completely disassemble the elastic clip 6, but only need to rotate the elastic clip 6 so that the gap that cannot be closed is aligned with the axial groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com