Lathe chuck for preventing workpiece from axially sliding

A technology of axial sliding and workpiece, which is applied in the direction of chucks, metal processing machinery parts, manufacturing tools, etc., can solve the problems of reducing processing accuracy, economic loss of enterprises, and scrapping of products in batches, and achieves high processing accuracy, convenient operation, The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

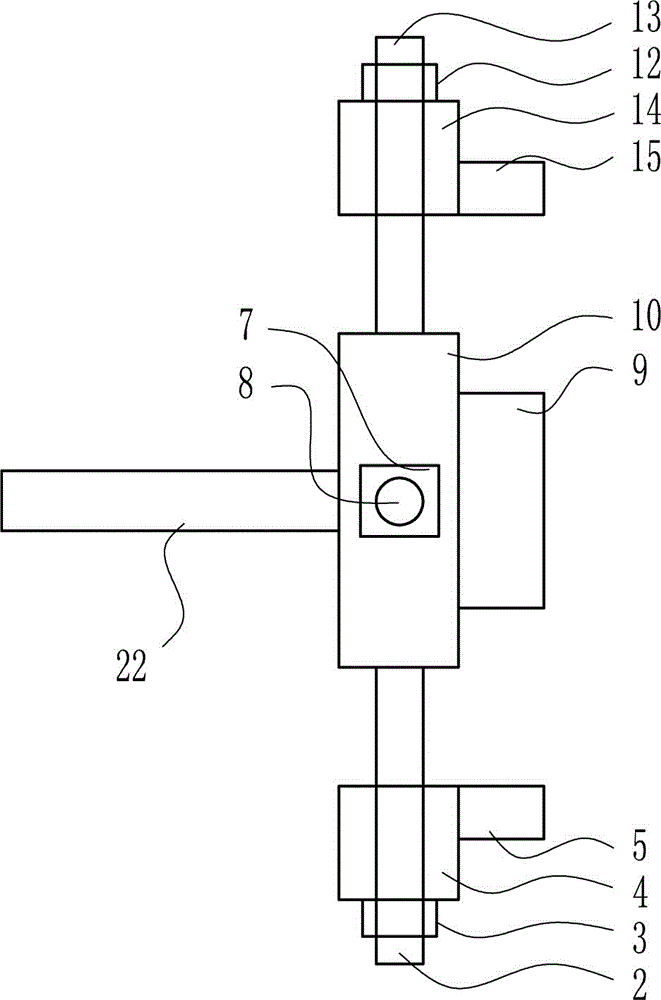

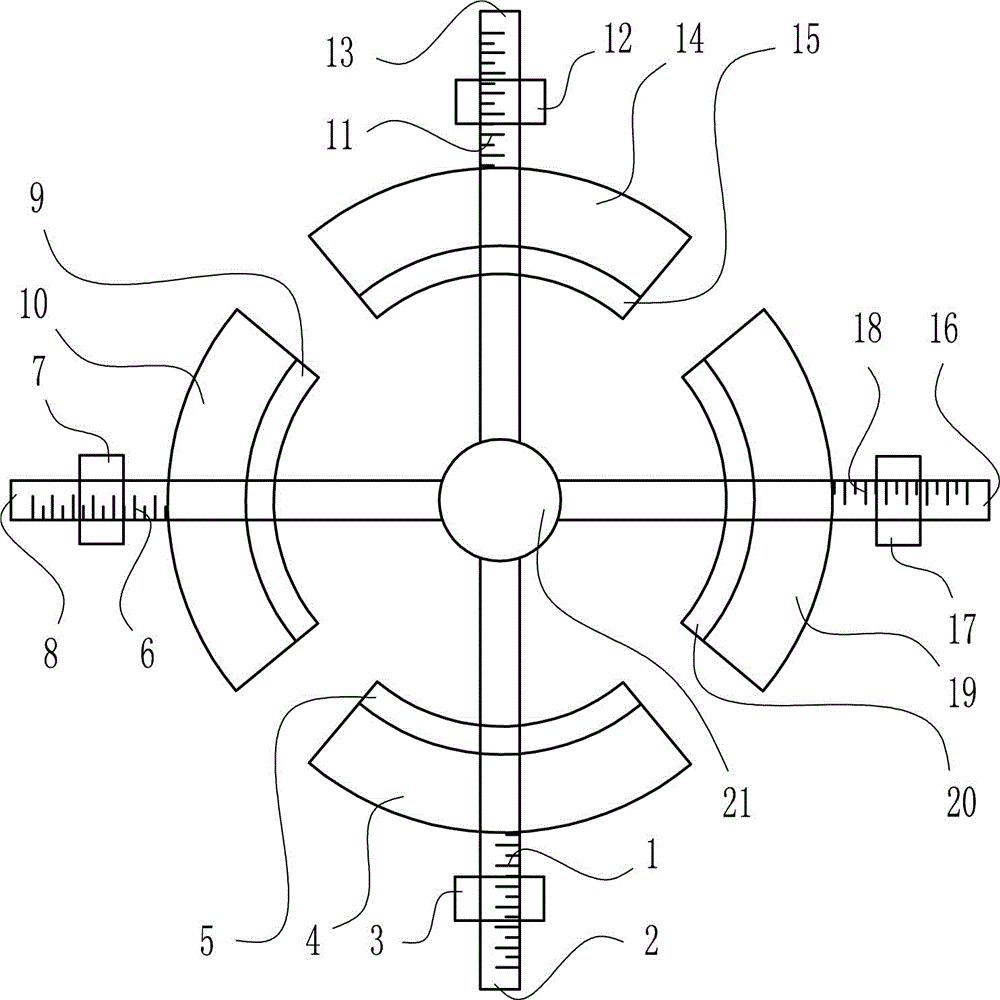

[0019] A chuck for lathes to prevent axial sliding of workpieces, such as Figure 1-2As shown, it includes guide rod Ⅳ2, nut Ⅳ3, fan-shaped fixing plate Ⅳ4, fan-shaped fixing block Ⅳ5, nut Ⅲ7, guide rod Ⅲ8, fan-shaped fixing block Ⅲ9, fan-shaped fixing plate Ⅲ10, nut Ⅱ12, guide rod Ⅱ13, fan-shaped fixing plate Ⅱ14 , fan-shaped fixing block II15, guide rod I16, nut I17, fan-shaped fixing plate I19, fan-shaped fixing block I20, disc-shaped electromagnet 21 and connecting shaft 22; The rod Ⅰ16 is connected with the disc-shaped electromagnet 21; the guide rod Ⅰ16 is provided with a thread, the guide rod Ⅰ16 is provided with a nut Ⅰ17, and the nut Ⅰ17 and the guide rod Ⅰ16 are threadedly connected; the guide rod Ⅰ16 is provided with a fan-shaped fixing plate Ⅰ19 , the fan-shaped fixing plate I19 and the guide rod I16 are set to be connected in a movable manner; the fan-shaped fixing plate I19 is arranged between the disc-shaped electromagnet 21 and the nut I17, and the fan-shaped f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com