Telescopic rotary hydraulic cylinder

A telescopic rotation and hydraulic cylinder technology, applied in the field of hydraulic cylinders, can solve the problems of complex structure and high cost of the overall hydraulic system, achieve the effects of improving operation stability and reliability, improving local stress concentration, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

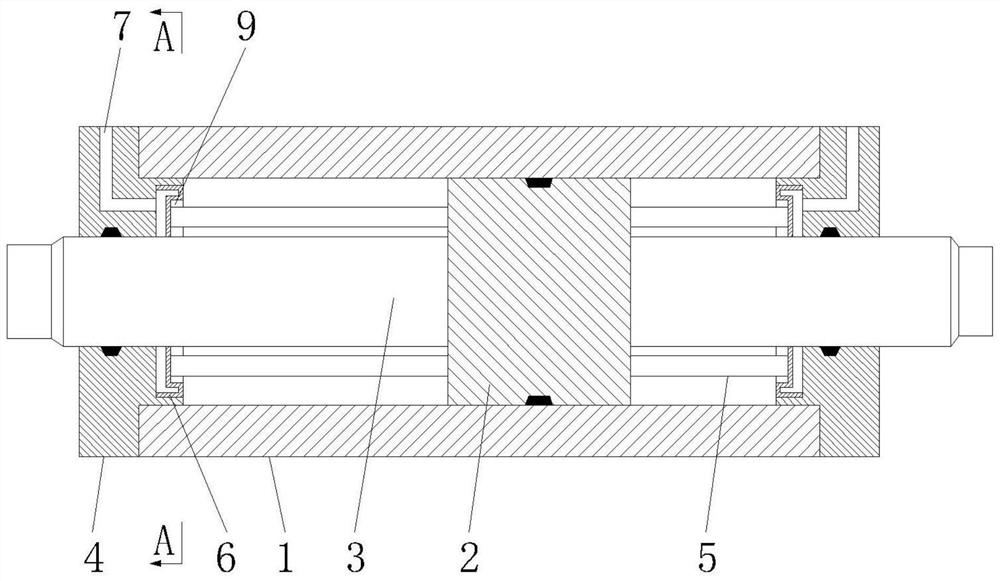

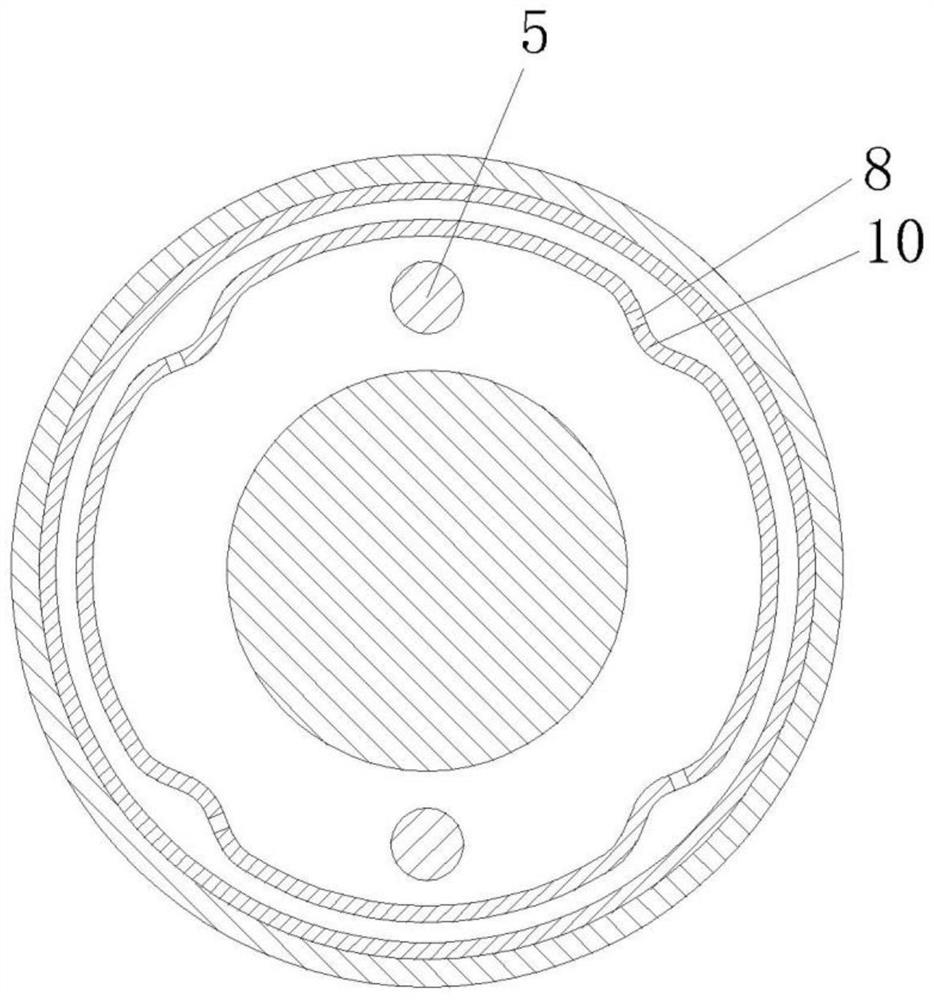

[0021] As shown in the figure: the telescopic rotary hydraulic cylinder in this embodiment includes a cylinder body 1, a piston 2, a piston rod 3 and end caps 4 covering both ends of the cylinder body, the piston rod and the end caps can be axially sealed and slid and The inner side of the end cover is connected with a rotating assembly for being driven and rotated by hydraulic oil injected into or out of the cylinder, and a guide rod 5 axially penetrating the piston is arranged in the cylinder, and the guide The rod is axially slidably matched with the piston, and both ends of the guide rod are connected to the rotating assembly to rotate synchronously with the rotating assembly. combine figure 1 As shown, the outer circle of the piston and the inner circle of the piston cylinder are axially slid and sealed through the sealing ring, and at the same time the piston and the inner circle of the piston cylinder are also rotationally matched, and the corresponding piston rod and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com