Hydraulic pipe bender

A pipe bender and hydraulic technology, which is applied in the field of hydraulic pipe benders, can solve the problems of low safety reliability and low pipe bending processing efficiency, and achieve the effects of meeting safe use requirements, saving raw materials, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

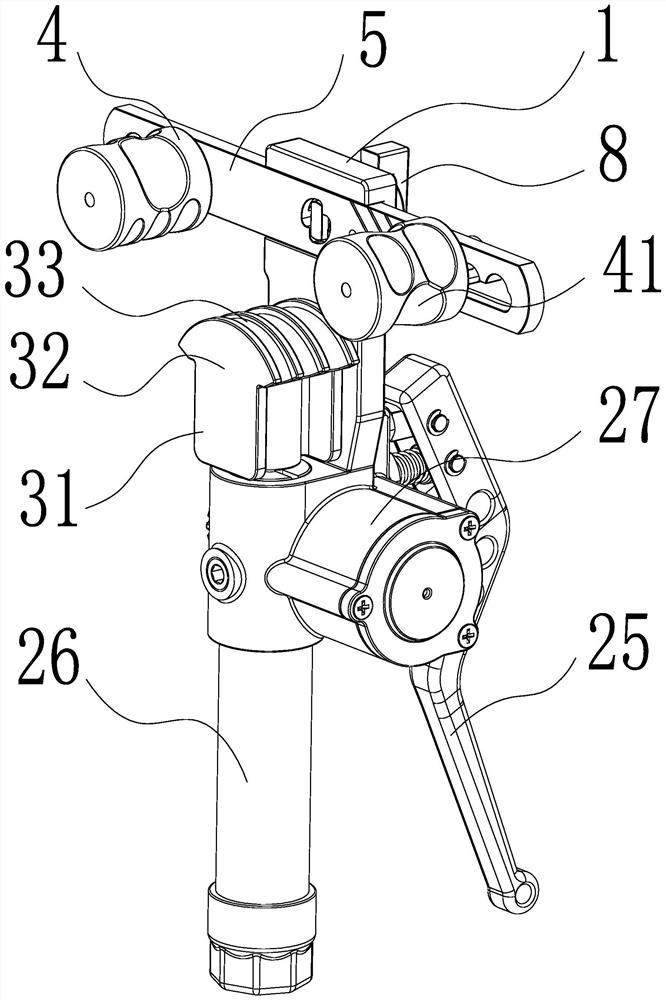

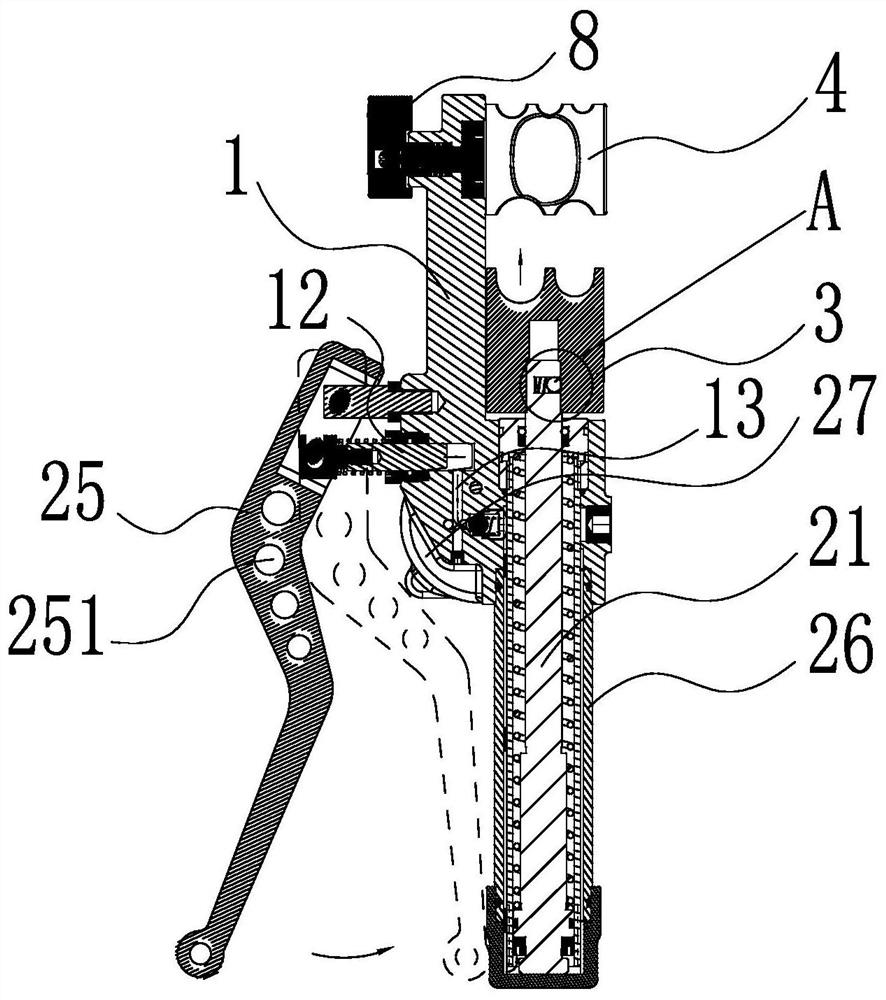

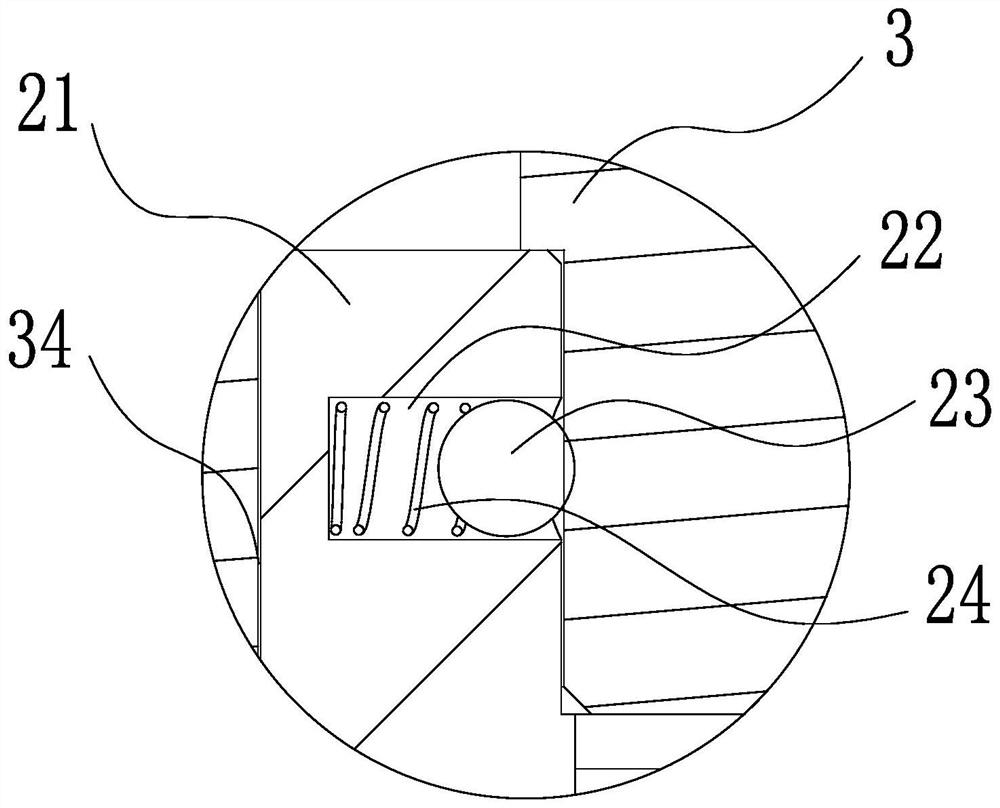

[0029] Such as figure 1 with figure 2 As shown, a hydraulic pipe bender of the present invention includes a body 1 and a hydraulic mechanism located on the body 1. The hydraulic mechanism includes an oil cylinder 26 fixed at the lower end of the body 1. The opening of the oil cylinder 26 faces upward, and the opening of the oil cylinder 26 The push rod 21 is interfitted and plugged in, and the top of the push rod 21 extends outside the opening of the oil cylinder 26, and an oil storage cylinder 27 and a hydraulic handle 25 are also installed on the outer ring surface of the body 1 near the opening of the oil cylinder 26, and the oil storage cylinder 27 passes through the oil inlet The oil circuit 13 and the oil return circuit are connected with the oil cylinder 26, and the connection end of the hydraulic handle 25 is connected to the body 1 in rotation, and the free end of the hydraulic handle 25 extends downward along the shape of the body 1, and a Several lightening holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com