Fuel supply cabin for ship

A technology for fuel supply and ships, which is applied in the field of ship fuel tanks. It can solve the problems of affecting the stability of material supply, the difficulty of controlling the pressure of fuel, and the inconvenient control of ship power, so as to achieve the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

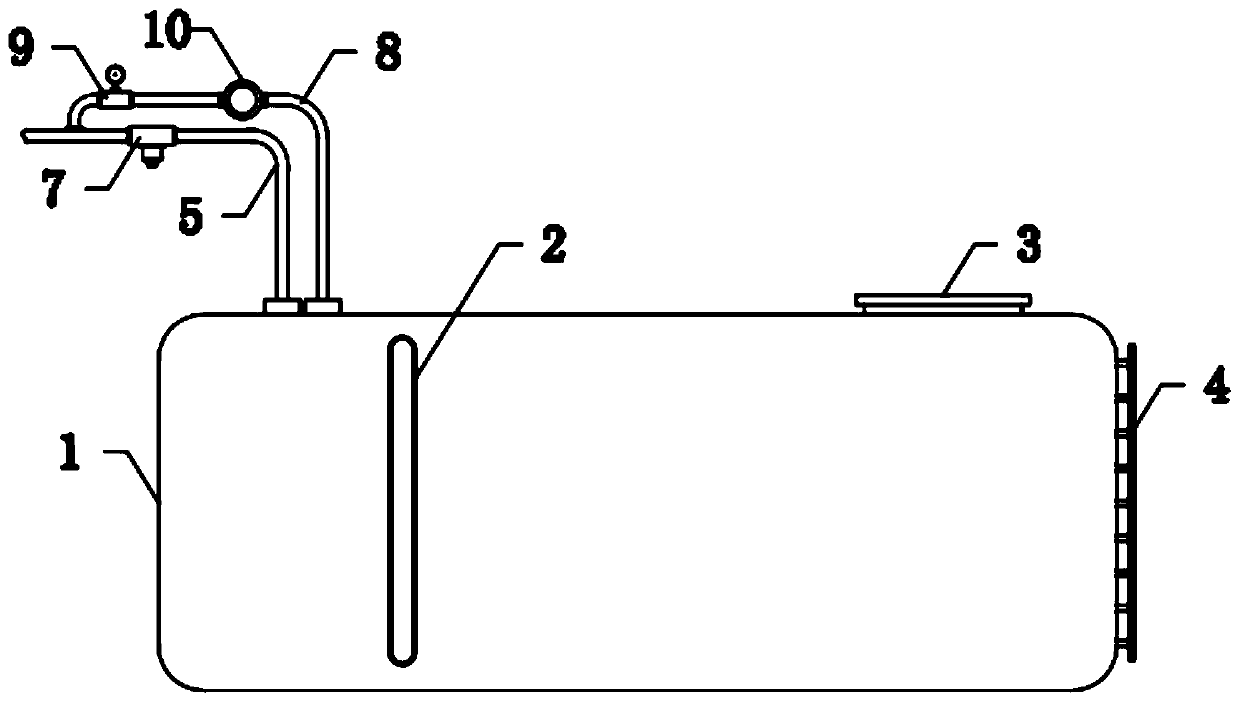

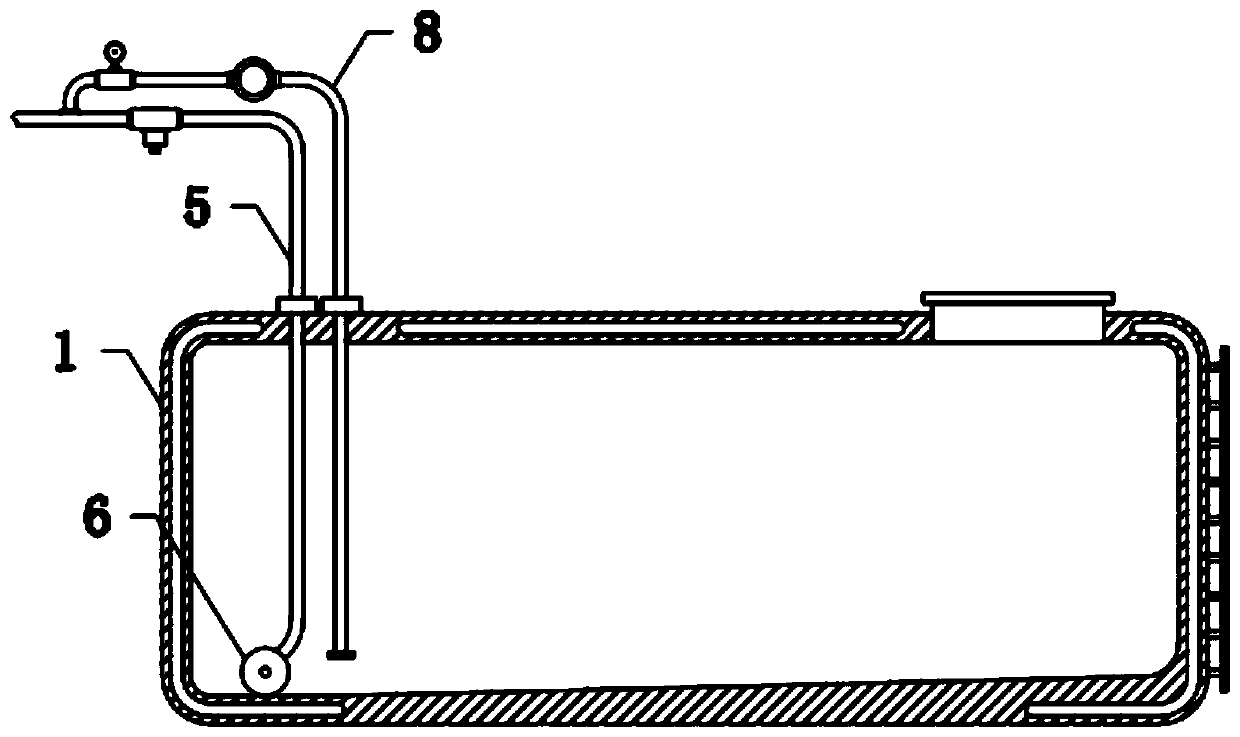

[0027] see Figure 1-3 , the present invention provides a technical solution: a fuel supply cabin for ships, including a cabin body 1, a main output pipe 5, and a filling and inspection port 3, the filling and inspection port 3 is arranged on the right side of the upper surface of the cabin body 1, and the main The output pipe 5 is longitudinally inserted on the left side of the upper surface of the cabin body 1, and the main output pipe 5 extends to the bottom of the inner cavity of the cabin body 1. 6. The fuel in the cabin body 1 is sucked through the main output pipe 5, and the setting of the filter screen head 6 can filter impurities in the fuel, thereby avoiding the impact of impurities on the fuel;

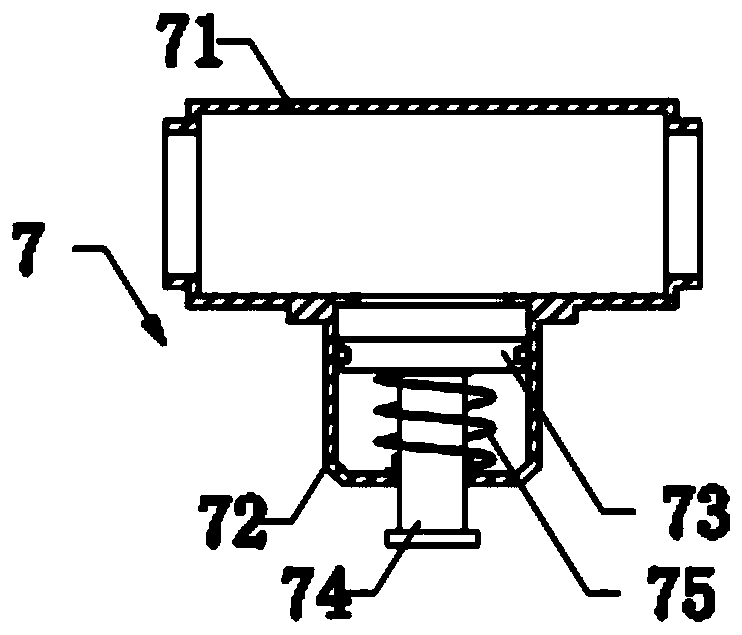

[0028] The pipeline of the main output pipe 5 is connected with a voltage stabilizing device 7, and the pipeline of the main output pipe 5 is also connected with an auxiliary branch pipe 8, and the connection between the auxiliary branch pipe 8 and the main output pipe 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com