Underground stereo garage

A technology of three-dimensional parking garage and parking platform, which is applied in the field of underground three-dimensional parking garage, can solve the problems that the number of cars cannot meet the huge demand, slow storage and retrieval speed, waste of building space, etc., and achieve compact structure, saving land space, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

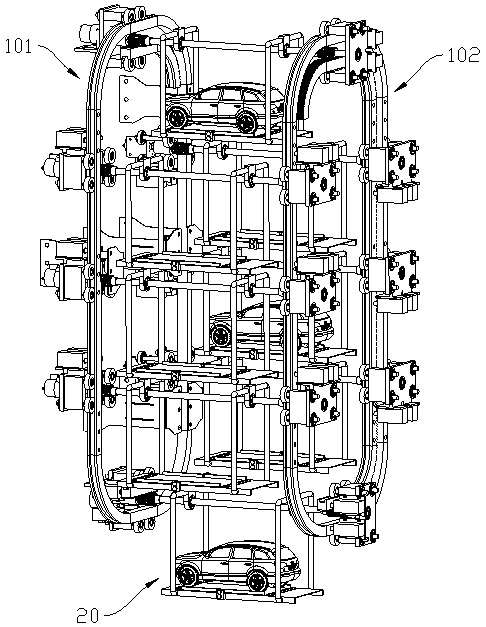

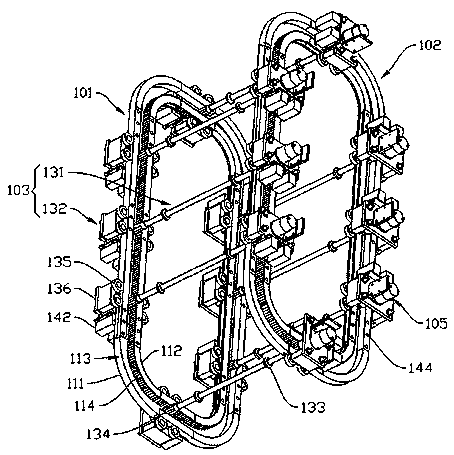

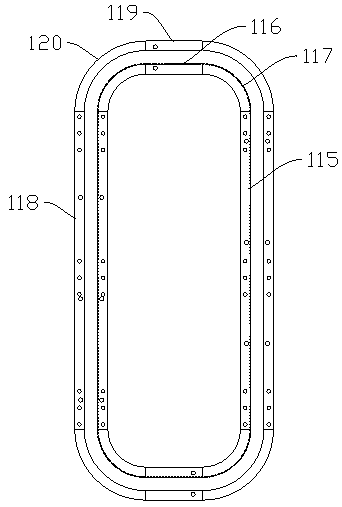

[0023] Such as Figure 1-4 As shown, the three-dimensional parking garage of the embodiment of the present invention includes a transmission assembly 10 fixed between underground walls and a plurality of frame plates 20, the frame plates 20 are connected to the transmission assembly 10, and the transmission assembly 10 includes a first slide assembly 101, The second sliding assembly 102, the connecting assembly 103, the motor 105 and the electromagnetic lock 142, the first sliding assembly 101 and the second sliding assembly 102 are arranged at intervals, the connecting assembly 103 connects the first sliding assembly 101 and the second sliding assembly 102, and the motor 105 is arranged On the connection assembly 103, as the power output of the drive connection assembly 103, the electromagnetic lock 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com