A method for adjusting the trough concentrator bracket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

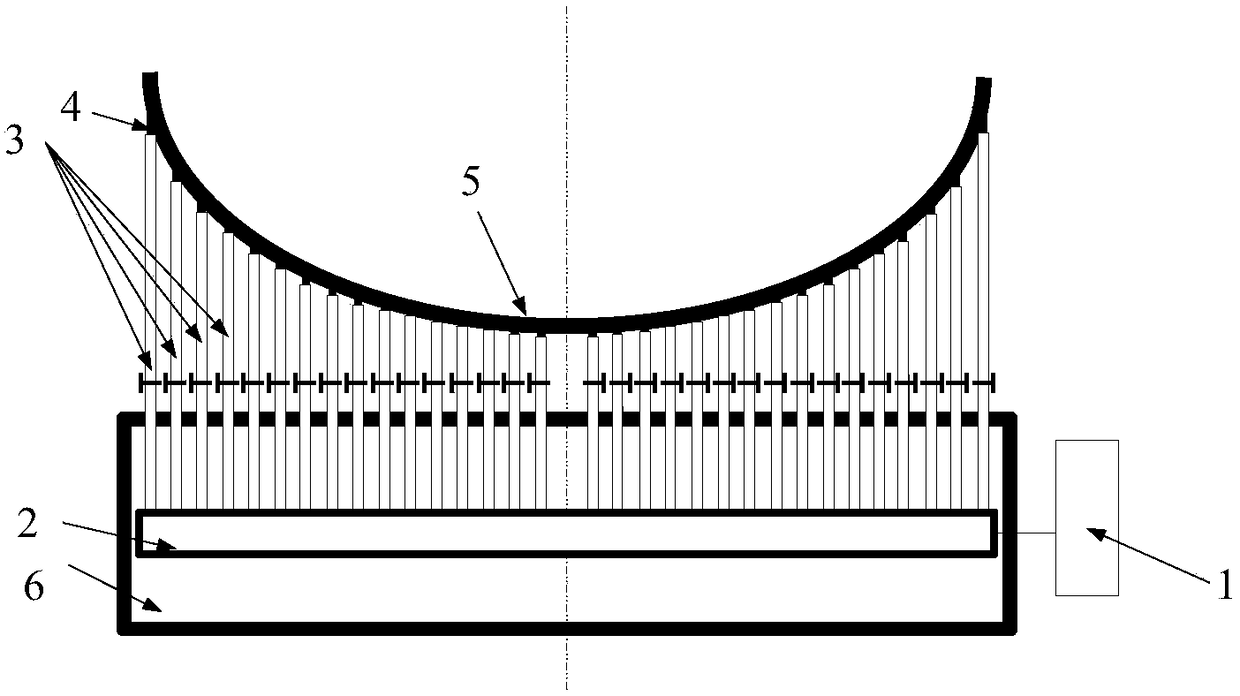

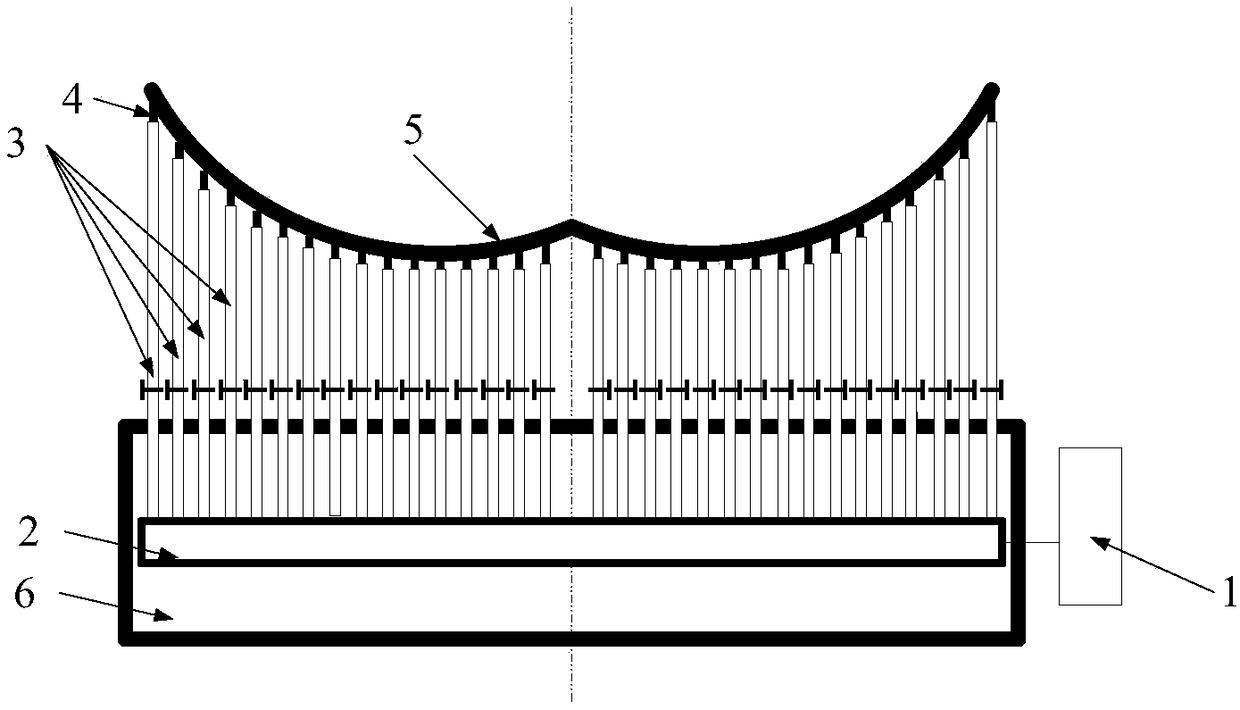

[0025] Such as figure 1 As shown, the trough concentrator of the present invention includes: hydraulic support assembly position control system 1, hydraulic transmission mechanism 2, several hydraulic support assemblies 3, heat-resistant glue or bolt connection structure 4, trough concentrator 5 and concentrator base6. The concentrator base 6 is in contact with the ground, and its width is greater than the opening width of the trough condenser. The hydraulic transmission mechanism 2 and the hydraulic support assembly 3 are installed on the concentrator base 6. The hydraulic support assembly 3 and the hydraulic transmission mechanism 2 are connected through a hydraulic oil circuit. The end of each hydraulic support assembly is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com