Valve element and valve comprising valve element

A valve core and valve technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of sealing failure, sealing ring easy to come out, etc., and achieve the effect of prolonging service life, enhancing sealing effect, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

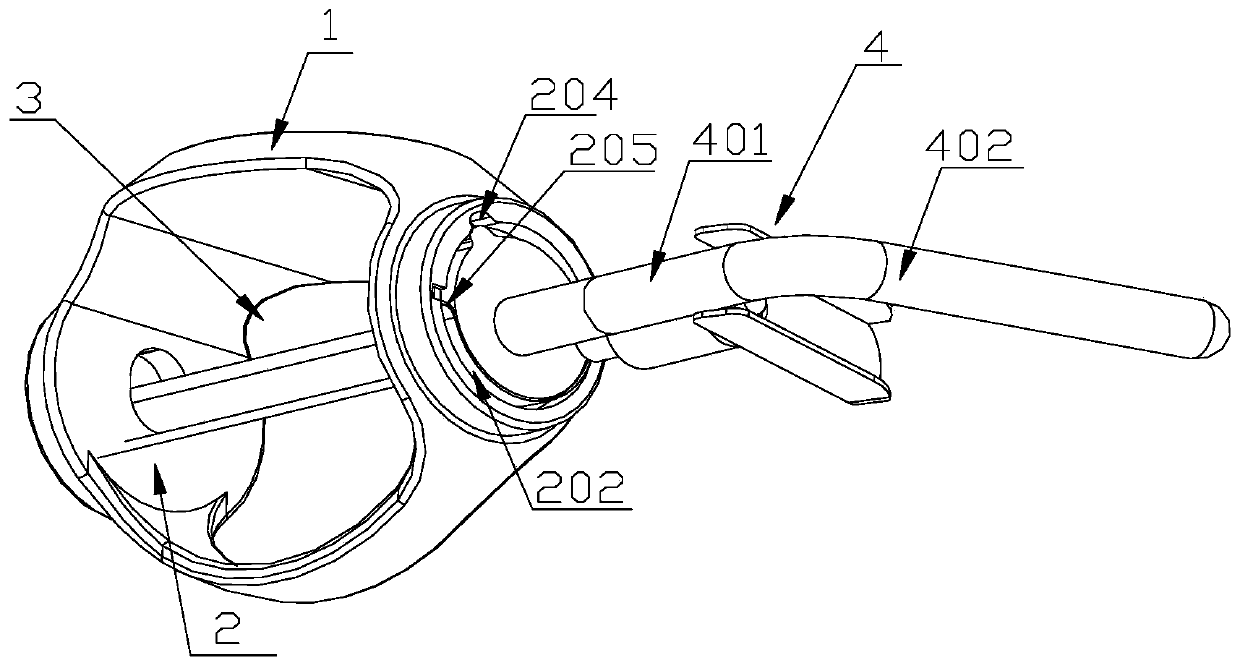

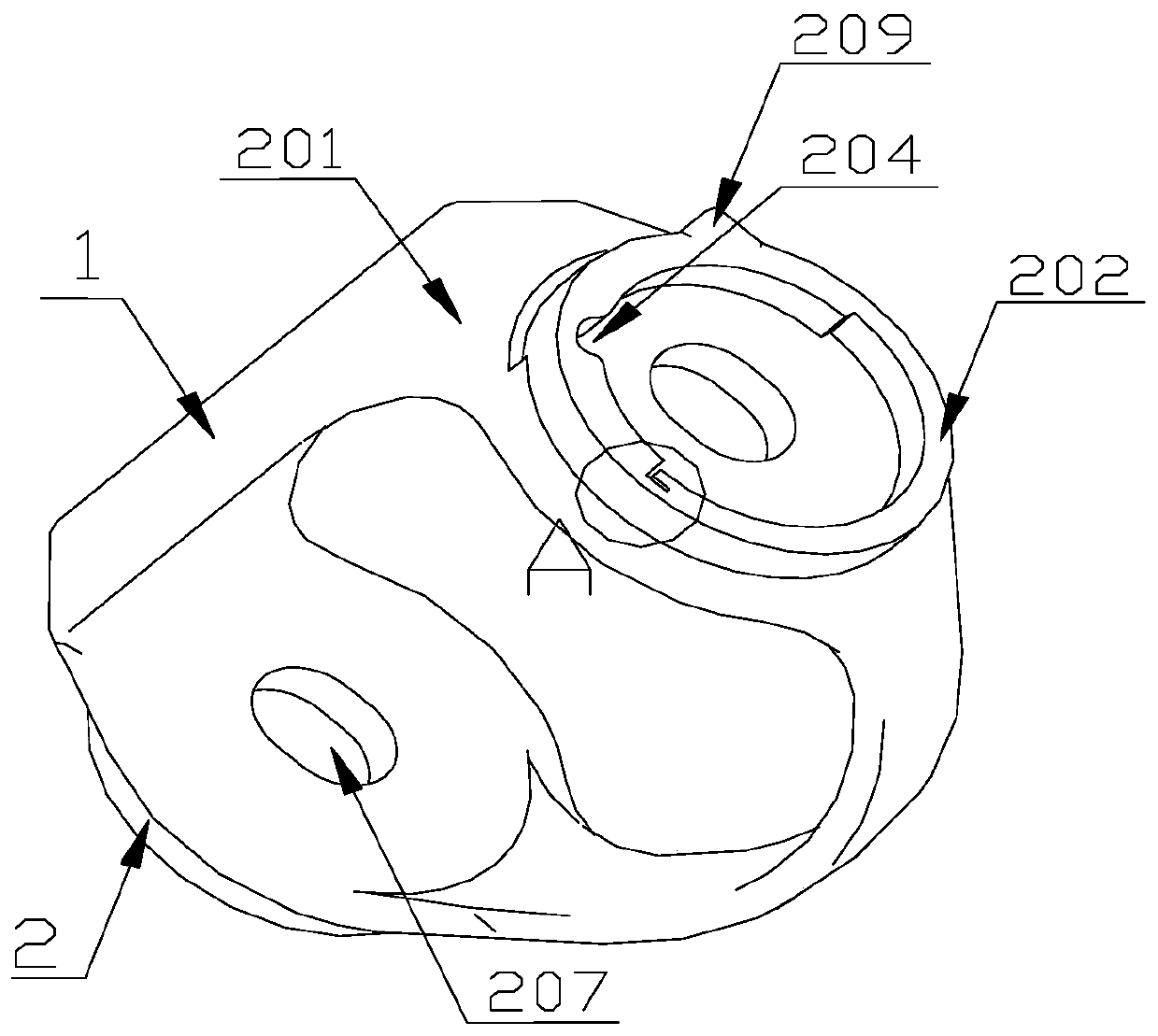

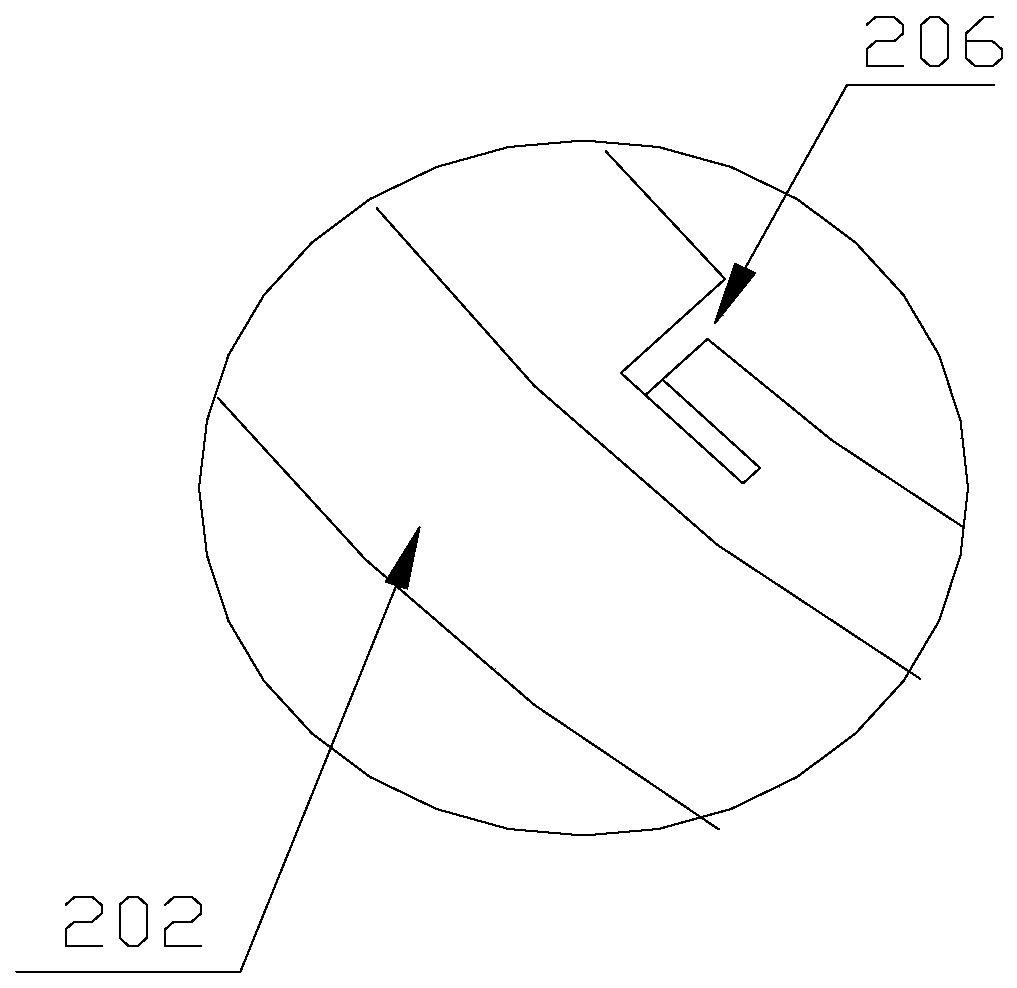

[0048] refer to Figure 1-Figure 7 , the connecting end 2 is oppositely fixed on the same side of the sealing end 1 , the sealing end 1 includes a sealing plate 101 and a sealing ring 102 , and the sealing ring 102 is fixed on the sealing plate 101 . The sealing ring 102 is located on the side away from the connecting end 2, the sealing plate 101 is circular, the diameter of the sealing ring 102 is smaller than the diameter of the sealing plate 101, when the sealing end 1 is in a sealed state , the sealing ring 102 abuts against the liquid outlet 5 . In order to strengthen the sealing effect between the seal ring 102 and the liquid outlet 5, a tapered guide surface 103 is fixedly arranged between the periphery of the seal ring 102 and the edge of the seal plate 101. In this embodiment, the tapered guide surface 103 and the seal The plate 101 and the sealing ring 102 are integrally structured. When the sealing ring 102 is in contact with the liquid outlet 5 and tends to be sea...

Embodiment 2

[0053] refer to Figure 1-Figure 4 The rotating shaft 4 includes a rotating shaft body 401 and a handle part 402 in an integrated structure, the rotating shaft body 401 is bent upwards to form a handle part 402, and a limited fixed block is movably connected at the joint between the rotating shaft body 401 and the handle part 402, so A limiting block 403 is fixed on the limiting and fixing block. Specifically, positioning pins are fixed on both sides of the rotating shaft body 401 , and the limiting and fixing block is movably connected with the rotating shaft 4 through the positioning pins. The shaft body 401 extends into the valve body to cooperate with the valve core, and the handle portion 402 is located outside the valve body. Specifically, the shaft body 401 passes through the second through hole 208 and the first through hole in sequence. The hole 207 matches with the connecting end 2 . Meanwhile, the shape of the cross section of the shaft body 401 is the same as tha...

Embodiment 3

[0055] refer to Figure 1-Figure 3 , Figure 8-Figure 10 , on both sides of the inner wall of the valve body, there are two installation grooves 7 for accommodating the connecting end 2, the installation grooves 7 are arranged along the length direction of the valve body, and the two installation grooves 7 are arranged at intervals, and the installation Two limiting grooves 701 are arranged in the groove 7 at intervals, and the limiting grooves 701 are used for accommodating the limiting protrusion 209 . That is to say, when the rotating shaft body 401 rotates, the limiting protrusion 209 moves in the two limiting grooves 701 , and the existence of the limiting protrusion 209 and the limiting groove 701 effectively limits the rotation of the rotating shaft body 401 . While the rotating shaft body 401 is rotating, the switching between the parallel state and the non-parallel state of the plane where the sealing end 1 and the liquid outlet 5 are located is realized.

[0056] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com