a soybean milk machine

A soymilk maker and machine head technology, which is applied in the field of food processing, can solve the problems of affecting the service life of the motor, high noise of the motor, and large wear of the shaft seal, and achieve the effects of prolonging the service life, reducing the torque, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

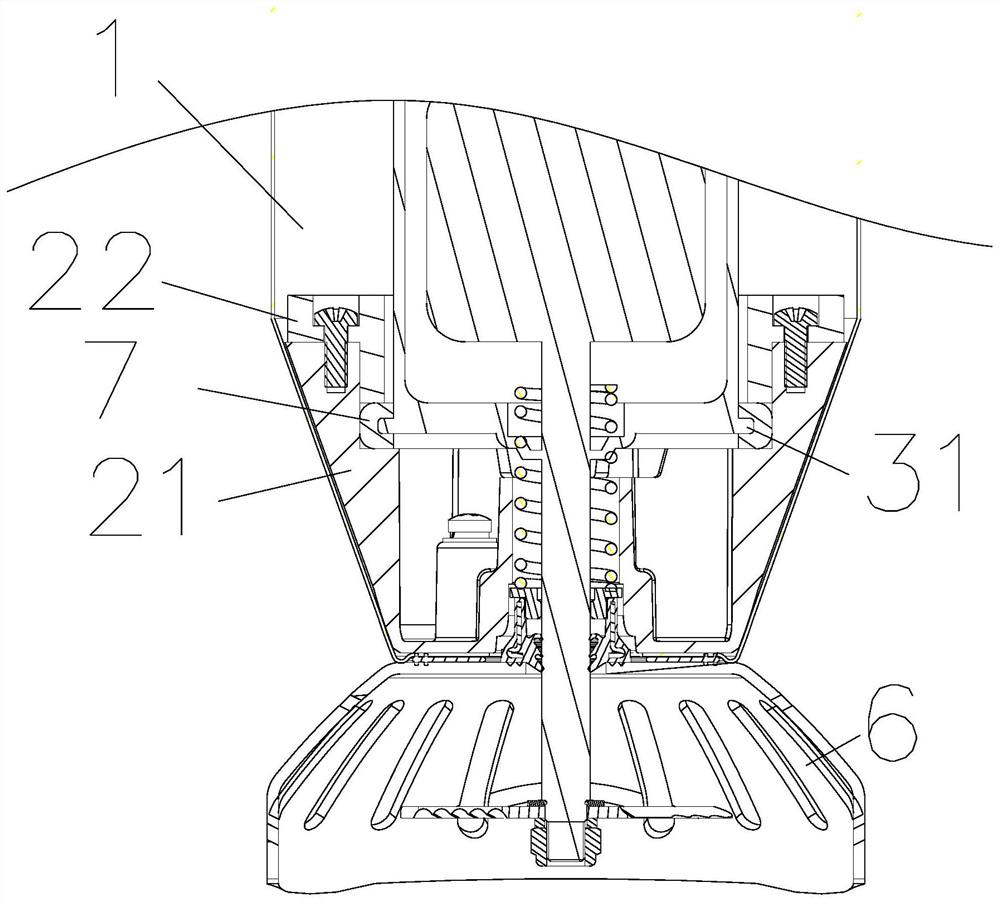

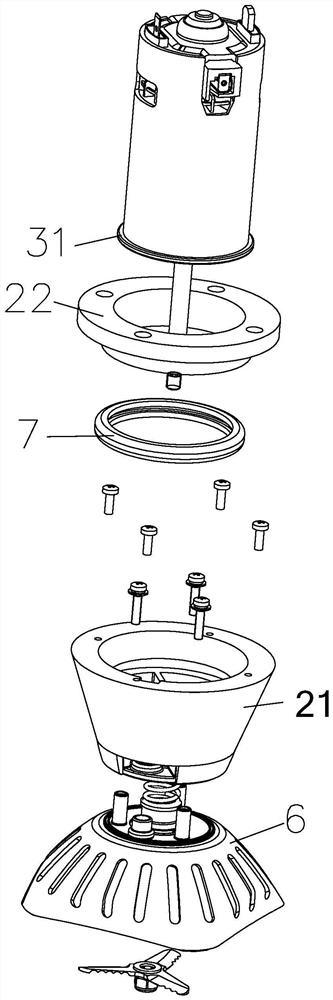

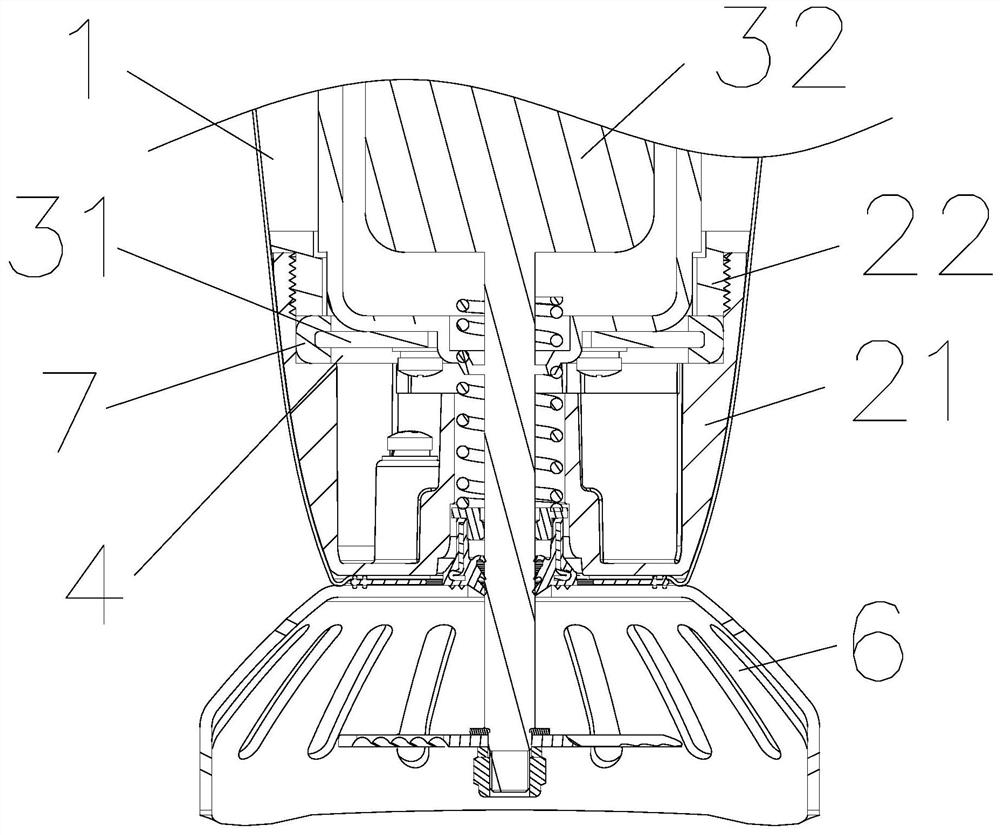

[0043] Soya-bean milk machine provided by the present invention, such as figure 1 with figure 2 As shown, it includes a cup body and a machine head placed on the cup body. The machine head includes: a metal lower cover 1; a motor mounting seat, which is arranged in the metal lower cover 1, and the motor mounting seat includes a first mounting seat 21 and a second mounting seat 21. Seat 22, the first mounting base 21 is positioned at the bottom of the second mounting base 22, and the middle part of the second mounting base 22 runs through; and a motor with a mounting portion 31, the second mounting base 22 is sleeved on the housing of the motor, and is connected to the second mounting base 22. A mounting base 21 is fixedly connected, and the mounting portion 31 is limited between the first mounting base 21 and the second mounting base 22 for mounting the motor on the motor mounting base.

[0044] In this soybean milk machine, the motor mounting base includes a first mounting ...

Embodiment 2

[0052] The difference between this embodiment and the first embodiment is that there is a movable gap between the axial mounting part 31 and the groove wall of the limiting groove 4, and the movable gap is 1-3 mm, which meets the requirements of radial runout and axial runout. Especially after installing the first shock absorber 7, the motor can better adjust its position, the shock absorption effect is better, and the noise generated is lower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com