Positioning and clamping mechanism for stock solution stirring barrel

A technology of clamping mechanism and mixing barrel, which is applied in the direction of mixer accessories, mixers, dissolving, etc., can solve the problems of loose locking and easy sliding, etc., and achieve the effect of firm clamping and positioning, not easy to slide, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

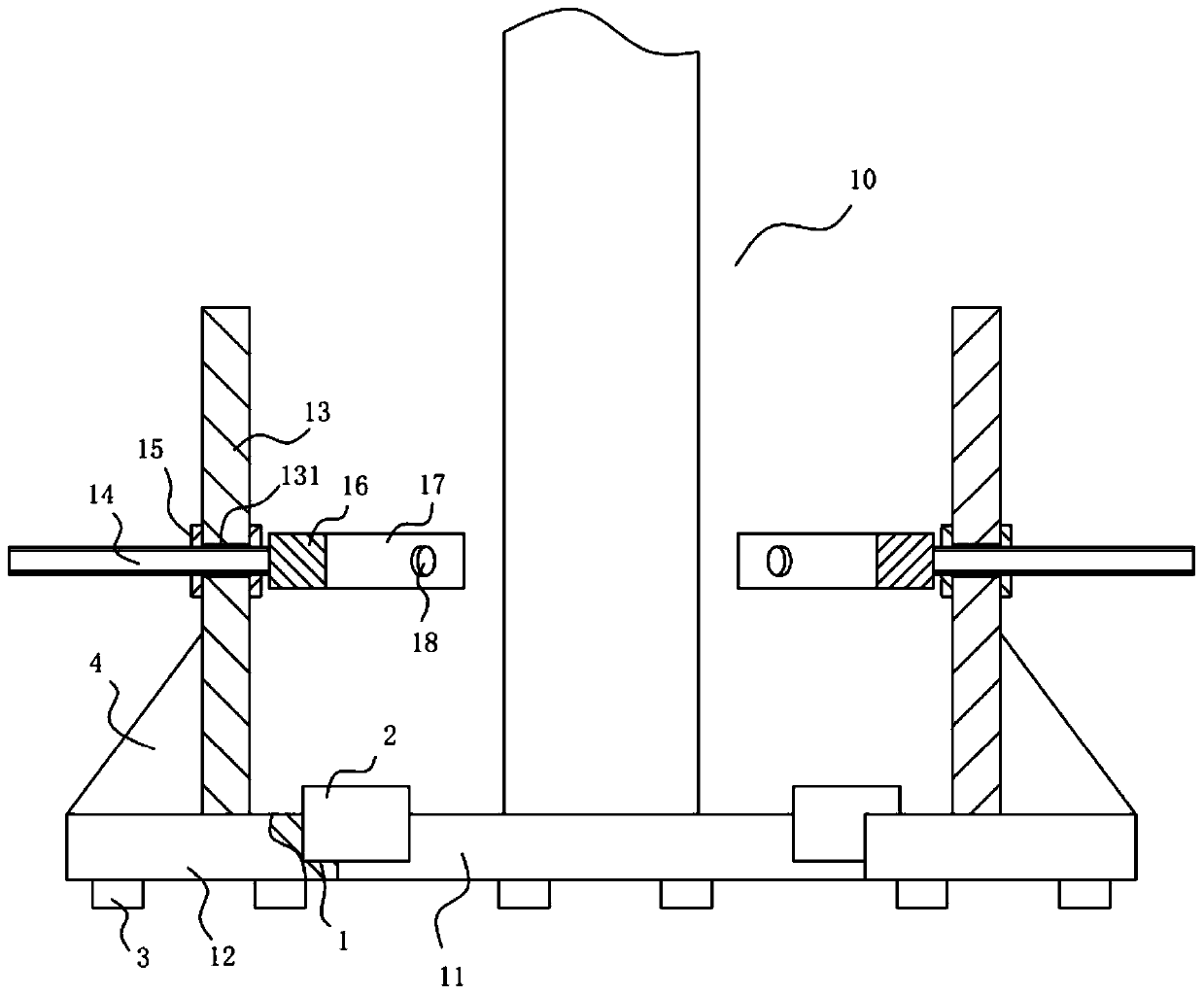

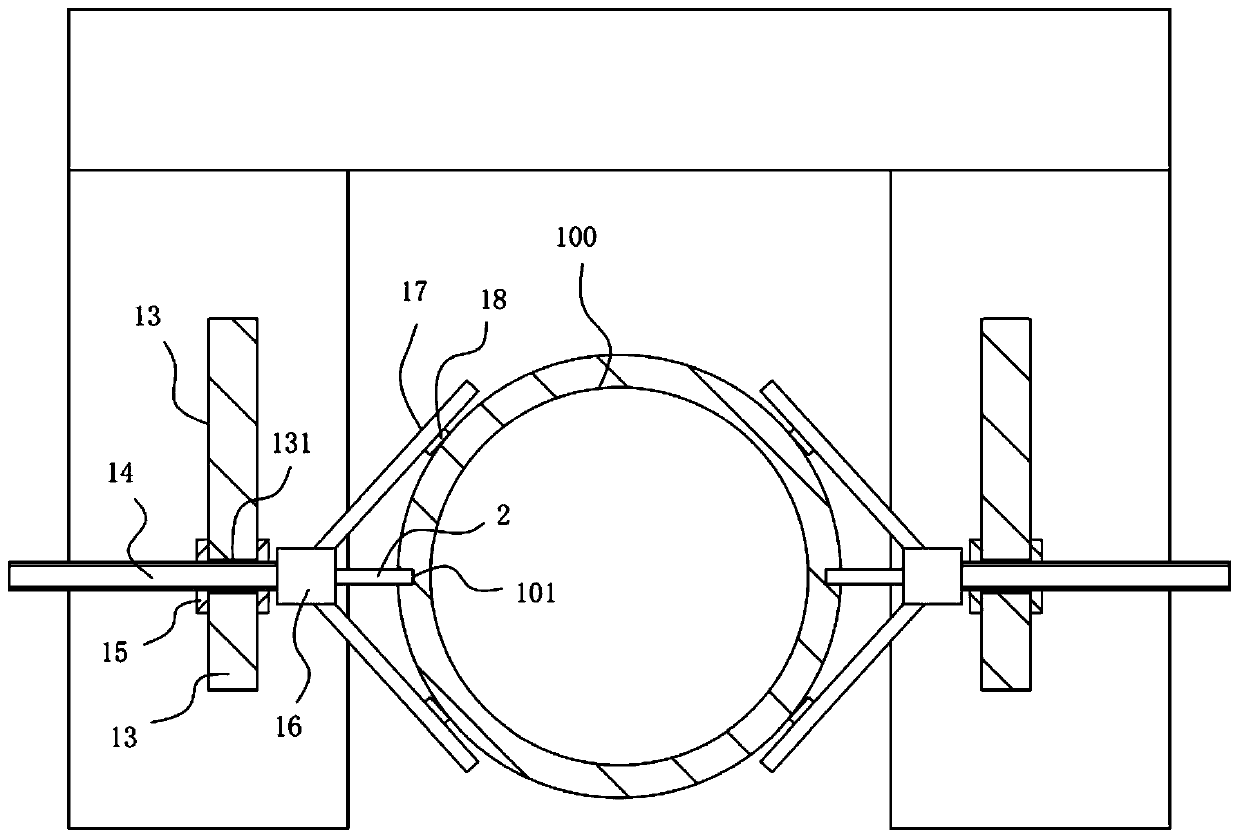

[0016] Example: see Figure 1 to Figure 2 As shown, a positioning and clamping mechanism for a stock solution mixing tank includes an underframe 10, and the underframe 10 includes a rear connecting plate 11, and front extension plates 12 are fixed on the left and right sides of the front wall of the rear connecting plate 11, two The top surface of the front extension plate 12 is fixed with a vertical plate 13, the middle part of the two vertical plates 13 is formed with a jack 131, the adjusting screw 14 is inserted in the corresponding jack 131, and the adjusting screw 14 is screwed with a Two locking nuts 15, the vertical plate 13 is clamped between the two locking nuts 15;

[0017] The inner ends of the two adjustment screw rods 14 on the two vertical plates 13 all stretch out the inner side walls of the vertical plates 13 and are fixed with a main connecting block 16, and the front and rear side walls of the main connecting block 16 are all fixed with inclined to rod 17. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com