Tumbling Automobile Welding Tooling

A technology for welding tooling and automobiles, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems affecting the continuity and efficiency of automobile production lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

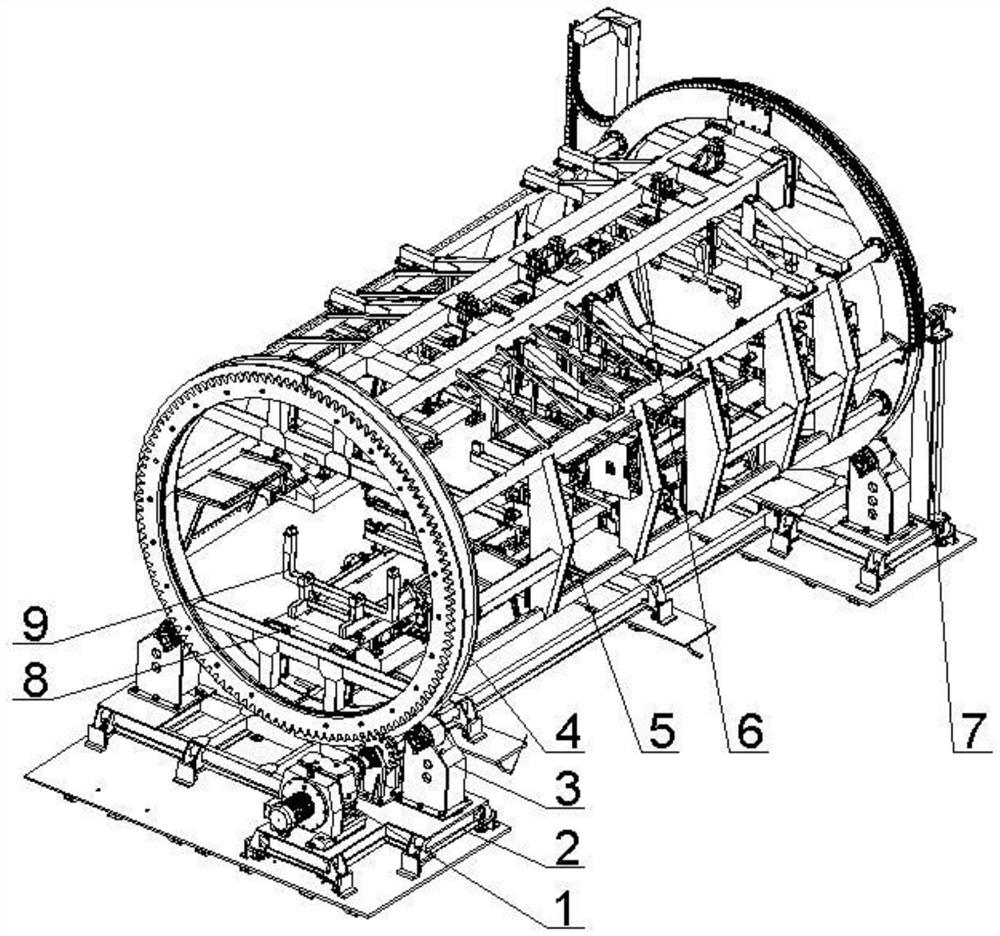

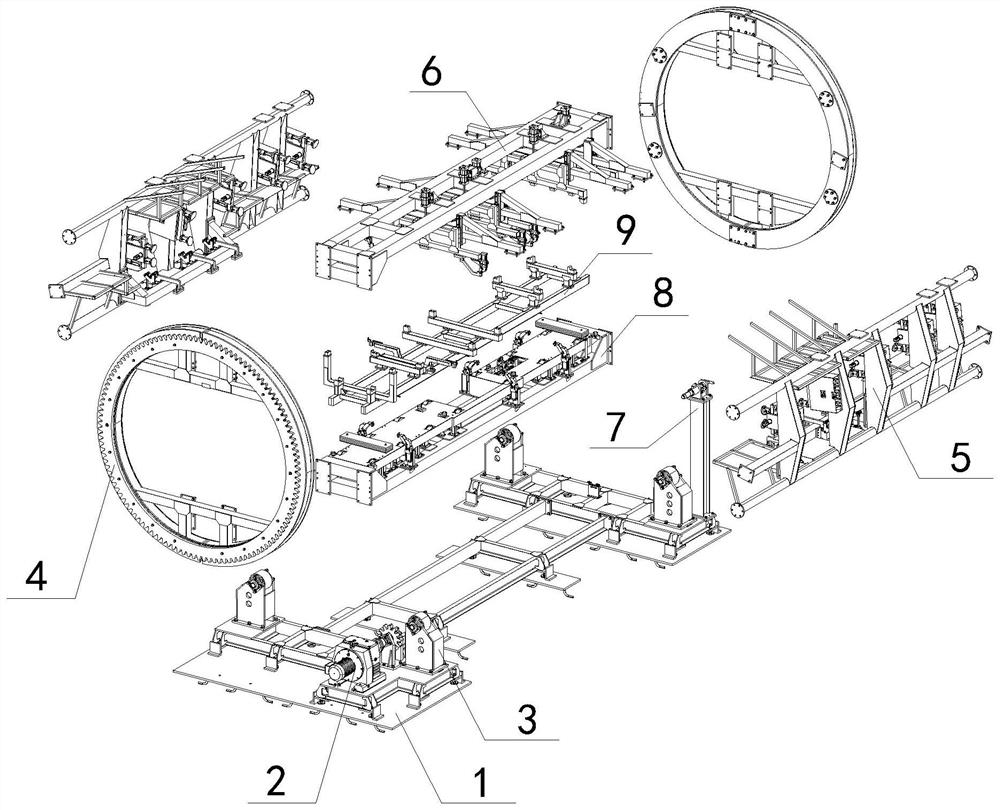

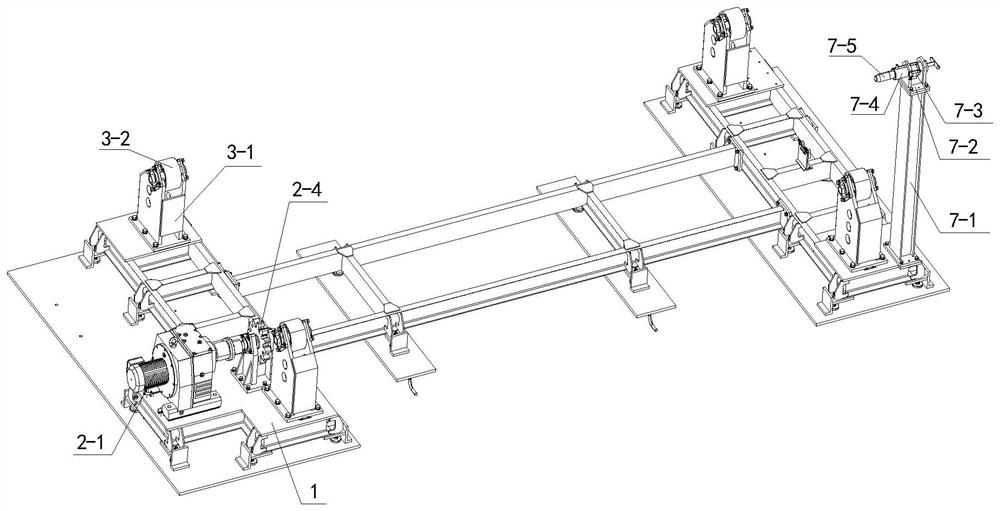

[0026] like Figure 1-9 As shown, a rolling type automobile welding tool, wherein, the longitudinal direction of the vehicle body is taken as the longitudinal direction, the width direction of the vehicle body is taken as the horizontal direction, and the height direction of the vehicle body is taken as the vertical direction, including a base 1, and two ends of the base 1 are fixed with roller mechanisms The power actuator 2 and the roller mechanism 3 are rollingly matched with a disc 4, and the power actuator 2 and the disc 4 are in transmission cooperation, and a side wall clamping device 5 for clamping the side wall of the vehicle body is fixedly connected between the two disks 4 , and the roof supporting device 6 clamped with the roof of the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com