Cosmetic bottle filling conveying hoisting frame

A technology for lifting racks and cosmetics, applied in the direction of conveyors, lifting devices, conveyor objects, etc., can solve the problems of error-prone transportation, large manual labor, low efficiency, etc., and achieve the effect of easy grasping, convenient processing and handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

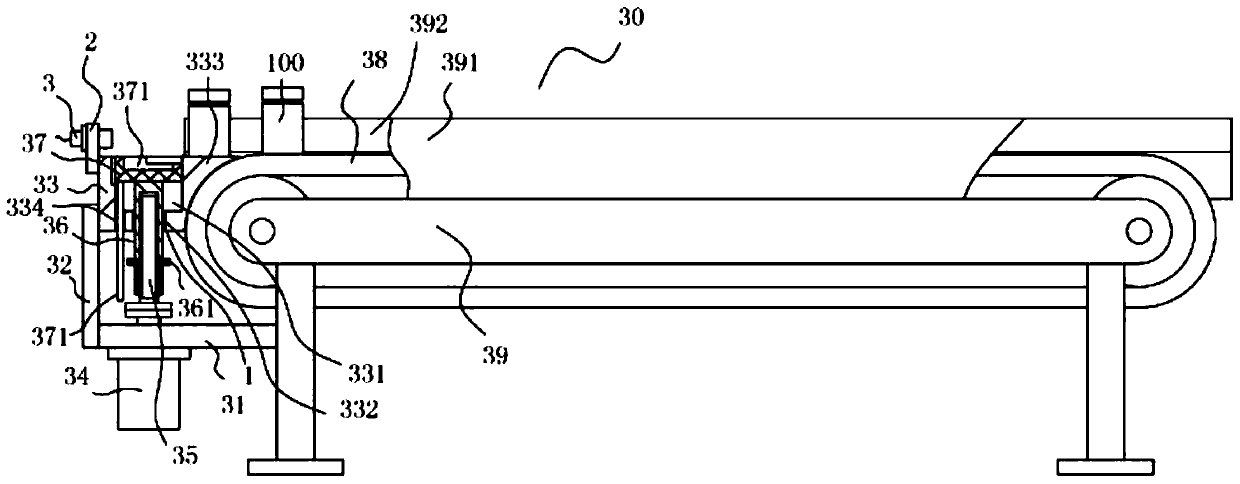

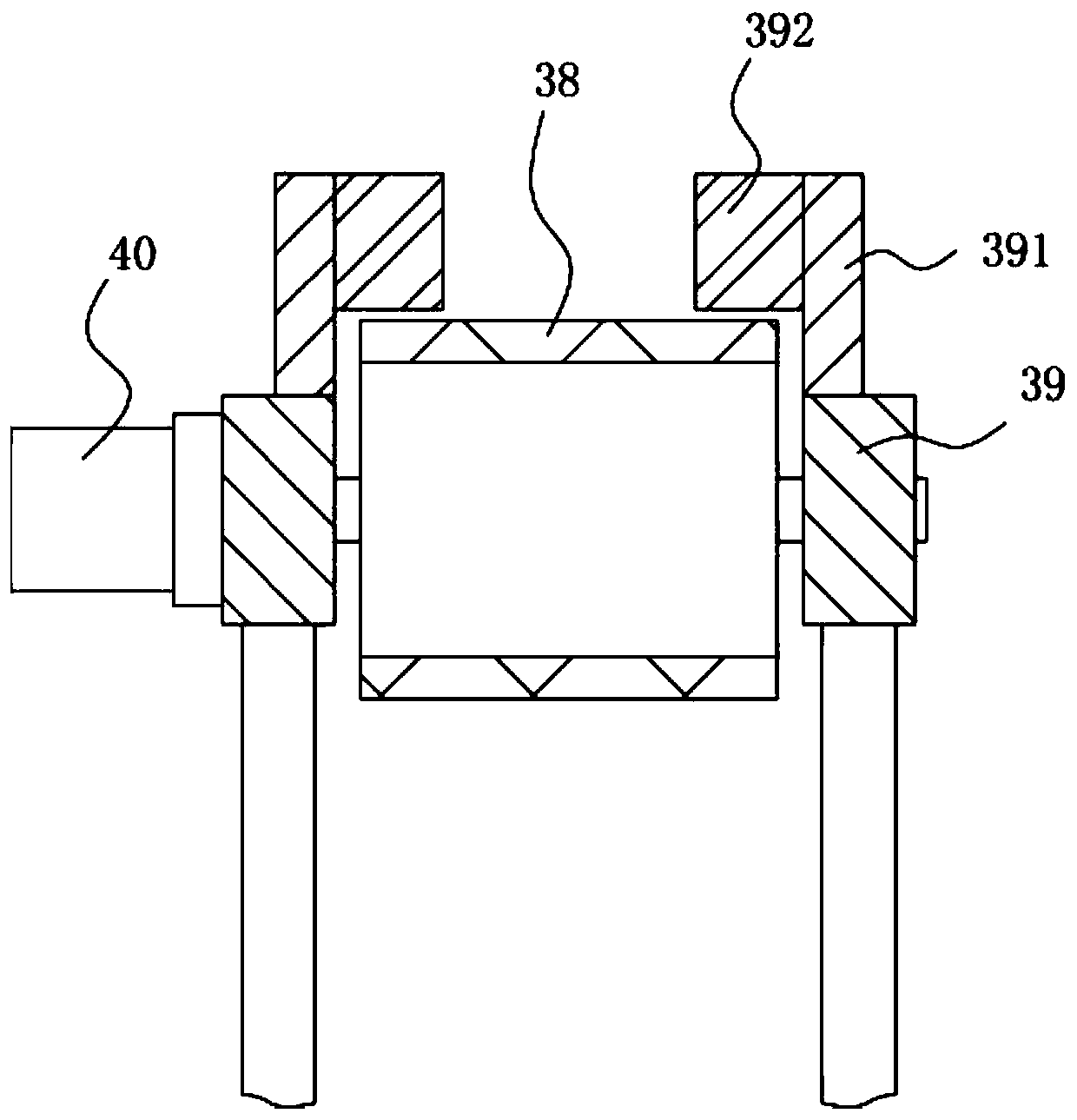

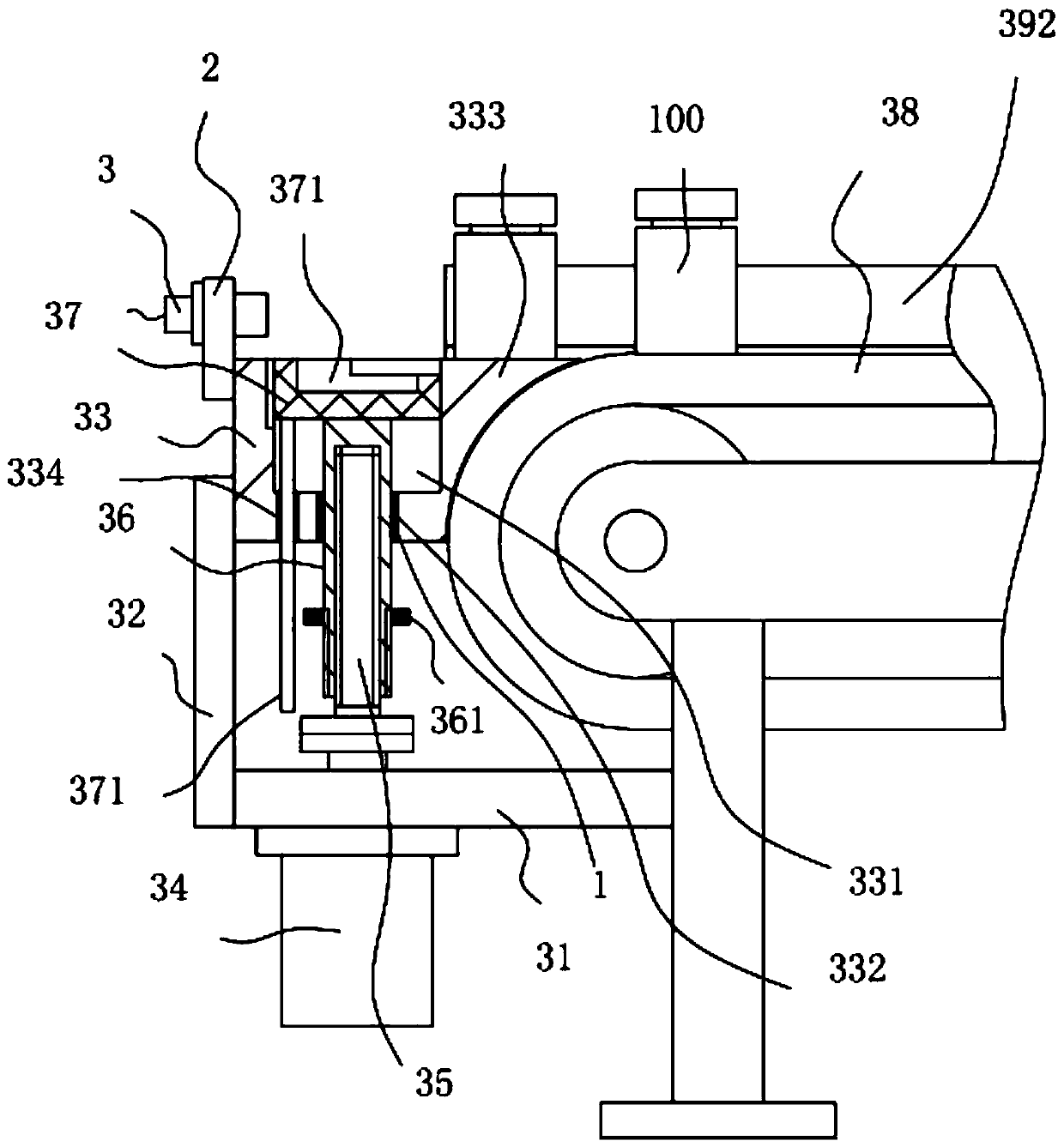

[0020] Example: see Figure 1 to Figure 3 Shown, a kind of cosmetic bottle conveying elevating frame, comprises conveying frame body 30, the left side wall of two legs of the left side of described conveying frame body 30 is fixed with horizontal connecting plate 31, the left side of horizontal connecting plate 31 A vertical plate 32 is fixed on the side wall, and a support block 33 is fixed on the top right side wall of the vertical plate 32. The middle part of the top surface of the support block 33 has a placement groove 331, and the middle part of the bottom surface of the placement groove 331 has a jack 332. , the bottom surface of the horizontal connecting plate 31 is fixed with a lifting motor 34, the output shaft of the lifting motor 34 passes through the horizontal connecting plate 31 and is connected with a vertical screw 35 through a shaft coupling, and the vertical screw 35 is screwed with a lifting screw sleeve 36, The lifting screw sleeve 36 is inserted into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com