Interconnected metering cover plate type valve port

A cover plate and valve port technology is applied in the field of aquatic crop irrigation control valves, which can solve the problems of not meeting the actual needs of intelligent metering irrigation, not setting sensor wireless communication ports, and not being able to accurately control the water level, etc., so as to ensure service life and reduce energy consumption. The effect of low power consumption and switching resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

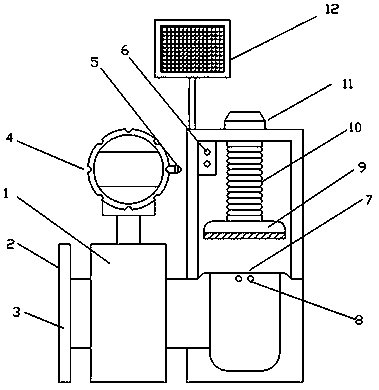

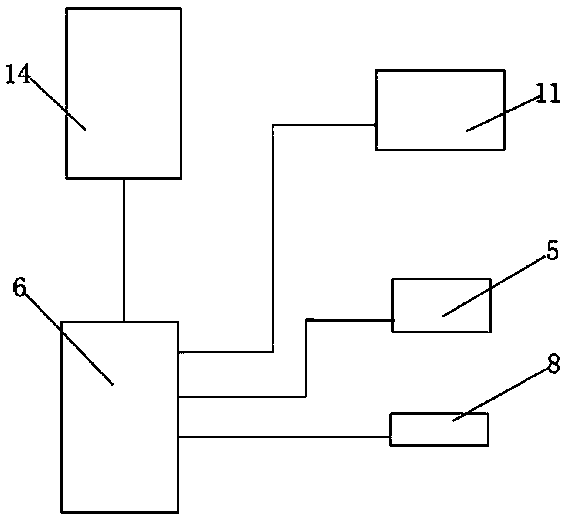

[0013] In order to further illustrate the present invention, introduce below in conjunction with accompanying drawing of description:

[0014] Refer to attached Figure 1-2 As shown, the interconnected metering cover plate valve port includes sensor 1, flange 2, water inlet 3, converter 4, communication interface 5, RTU circuit board control room 6, water outlet 7, water level electrode 8, cover plate 9 , a corrugated waterproof telescopic sleeve 10, an electric push rod 11, a photovoltaic power generation panel 12, a water inlet 3 is arranged on the left side of the central pipe of the sensor 1, a flange 2 is arranged on the left side of the water inlet 3, a converter 4 is arranged on the upper end of the sensor 1 and Communication interface 5, a water outlet 7 is designed on the right side of the sensor 1, the mouth of the water outlet 7 is designed to face upwards, a water level electrode 8 is arranged inside the mouth of the water outlet 7, and an inverted U-shaped frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com