Upset forging shearing straightening testing machine

A technology of straightening test and upsetting mechanism, which is applied in the direction of applying stable shear force to test the strength of materials, other manufacturing equipment/tools, instruments, etc., and can solve problems such as slow loading speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

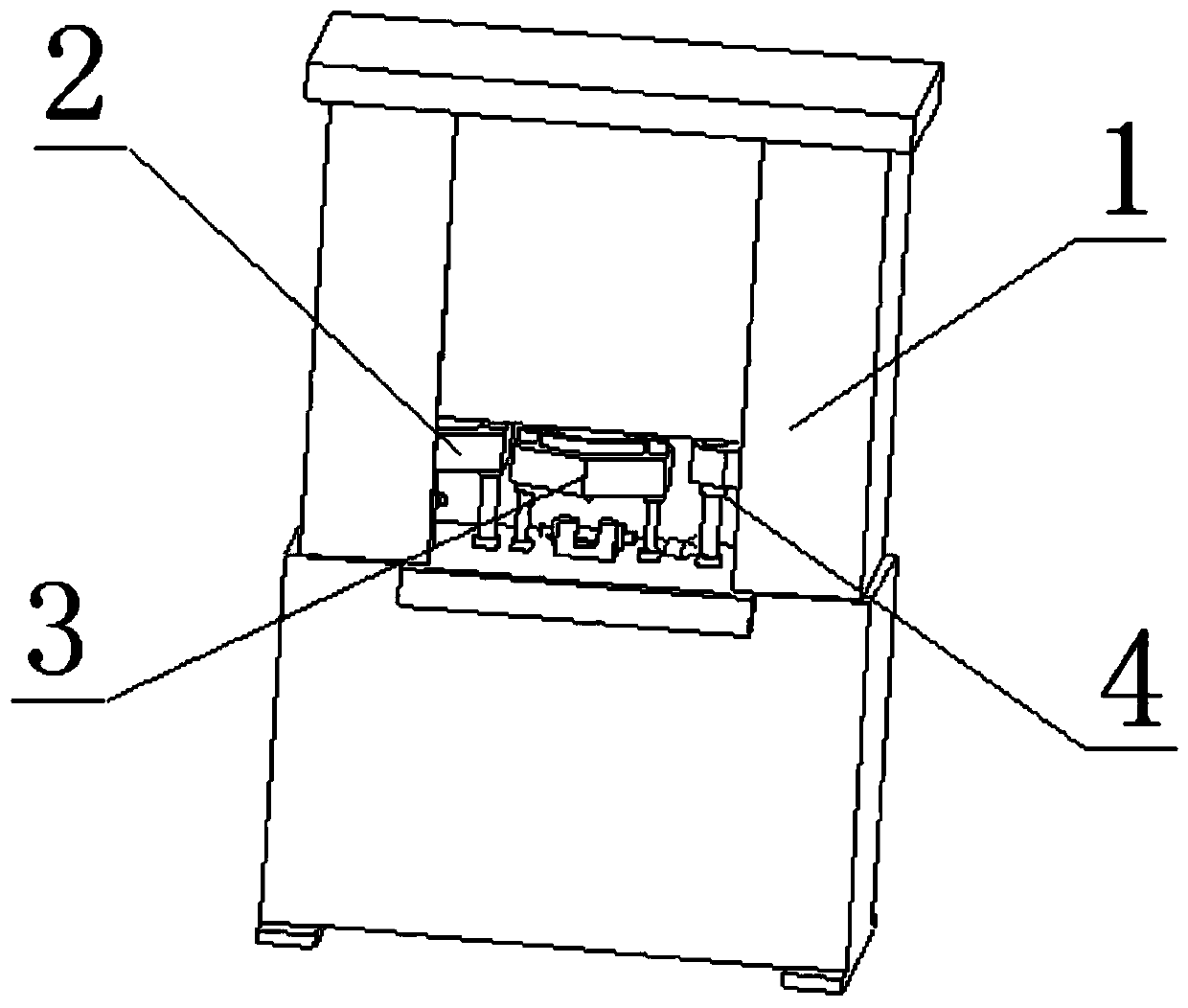

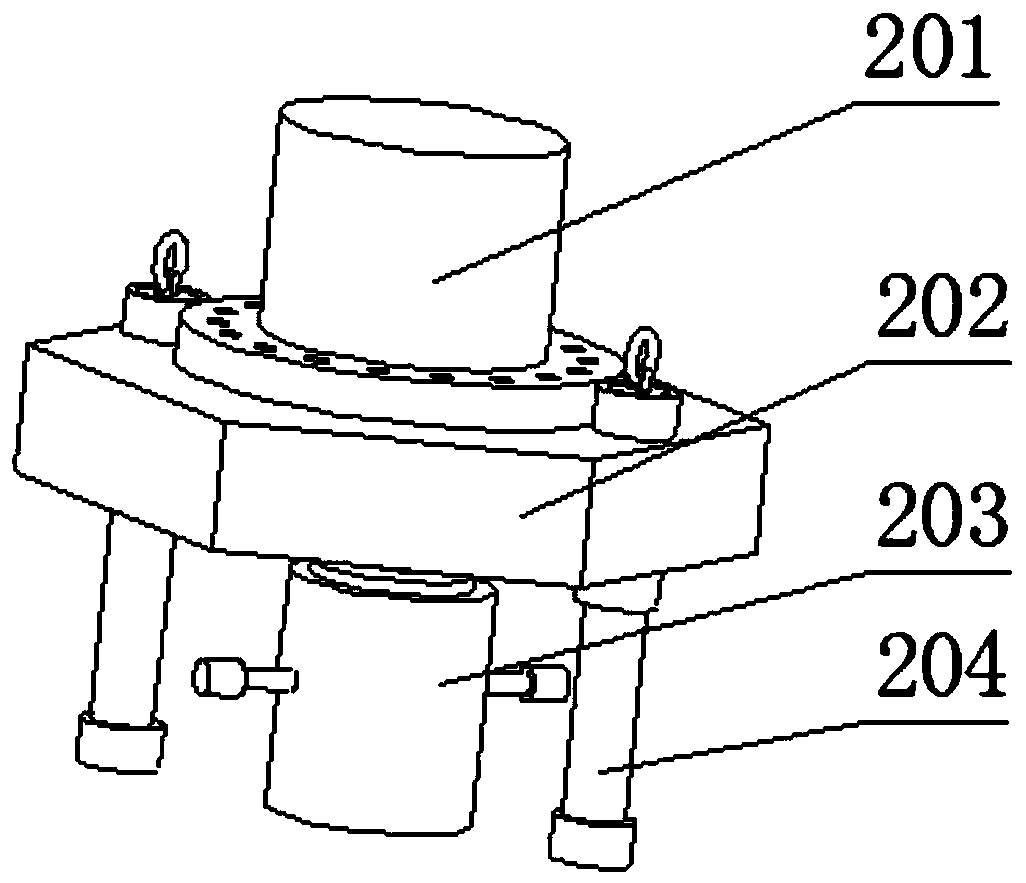

[0010] 1. See figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a kind of upsetting shear straightening testing machine of the present embodiment comprises: bed 1, upsetting mechanism 2, shearing mechanism 3 and straightening mechanism 4, wherein bed 1 and upsetting mechanism 2 are connected by bolts, work Put the sample on the lower heading head 203, and close the bed door 101. When the force reaches the requirement, it can be dropped quickly, and the change of the sample can be used to determine whether it is qualified. The shearing mechanism 3 and the straightening mechanism 4 It is connected with the bed 1 by bolts, wherein the workpiece table 304 and the workpiece supporting table 403 are connected by bolts, and respectively play a role in fixing the workpiece.

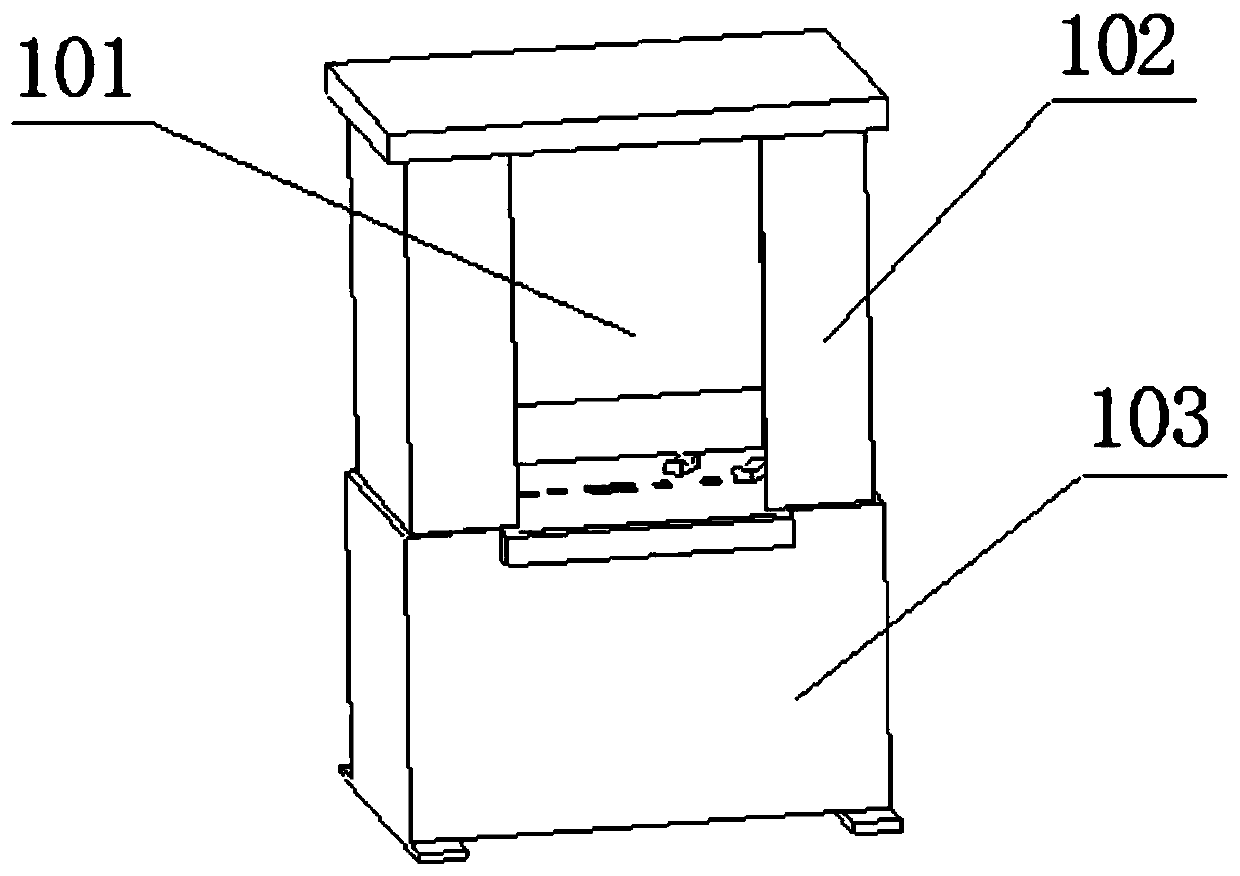

[0011] 2. See figure 2 , the bed 1 is composed of a bed door 101, a protective frame 102, and a bed platform 103, wherein the bed door 101 can move up and down in the protective frame 102, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com