Multi-joint combined motion flexible manipulator driving device

A flexible manipulator and joint motion technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as underactuated stability, and achieve the effects of improving stability, good practicability, and increasing controllability and stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

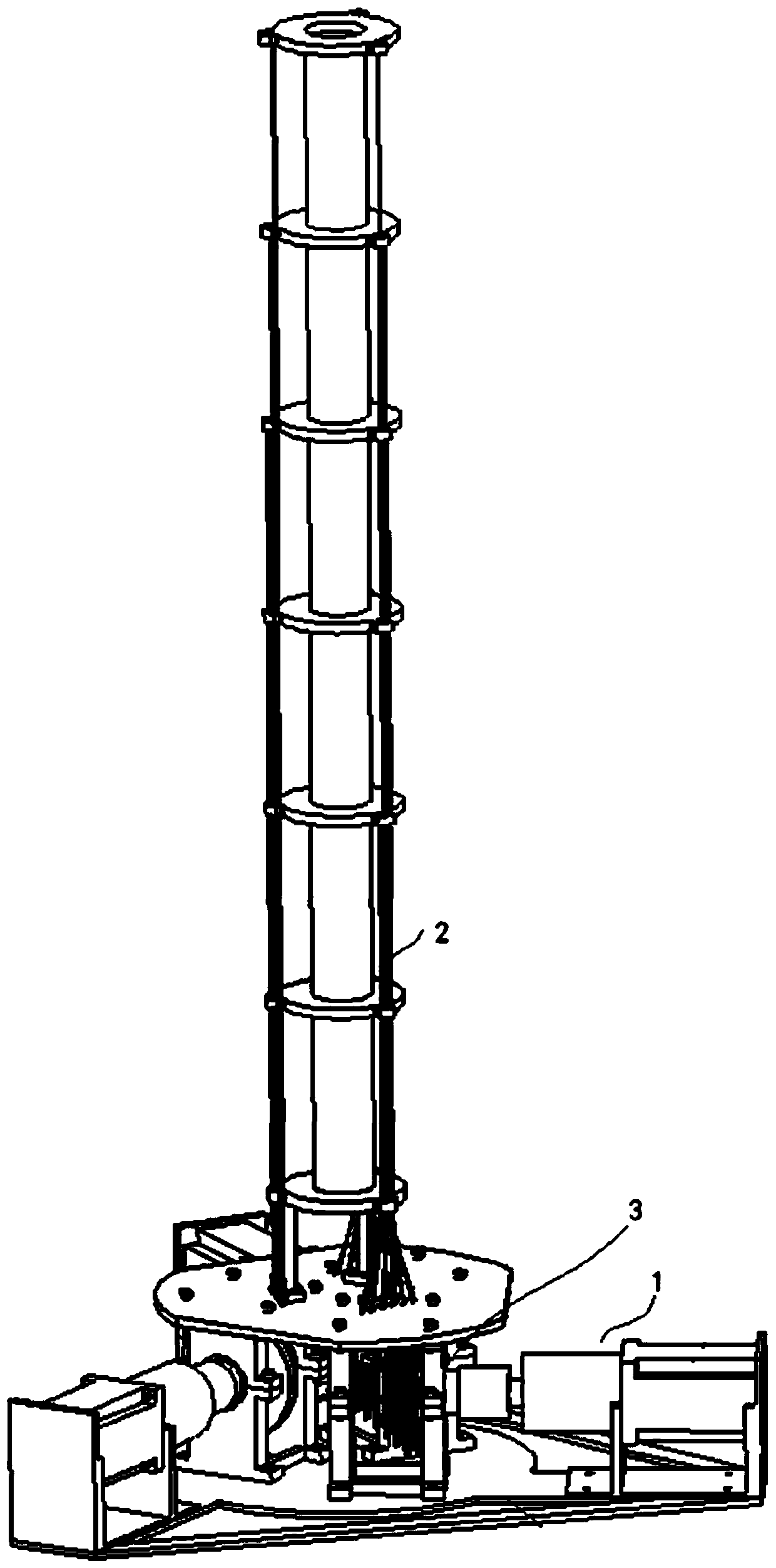

[0039] Such as figure 1 As shown, a multi-joint joint motion flexible manipulator driving device is applied to a flexible manipulator including multiple joints, including N groups of drive modules 1; N groups of ropes 2, and each group of ropes 2 includes n ropes 2 N groups of winding modules 3, each group of winding modules 3 is provided with at least n winding mechanisms; in the same group of ropes 2, different ropes 2 are driven by the same group of winding modules 3 and drive modules 1, and Different ropes 2 are used to drive different joints of the flexible robotic arm. One end of the rope 2 is fixedly connected to different winding mechanisms in the same group of winding modules 3, and the other end of the rope 2 is respectively wound behind the corresponding winding mechanism. , passing through the first threading hole of each joint from the end in turn until reaching the corresponding joint driven by the rope 2 and then connected to it; the output end of each group of ...

Embodiment 2

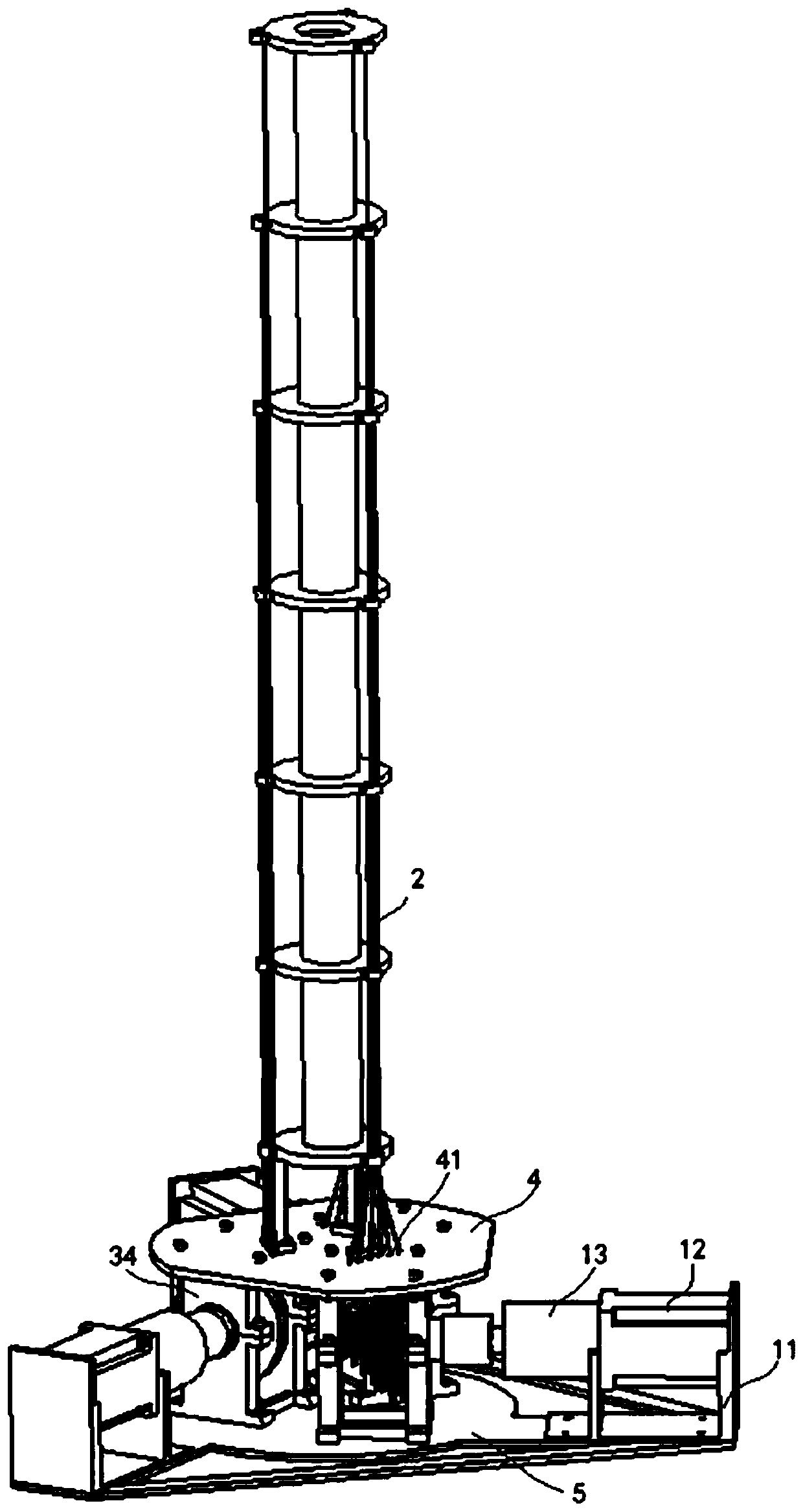

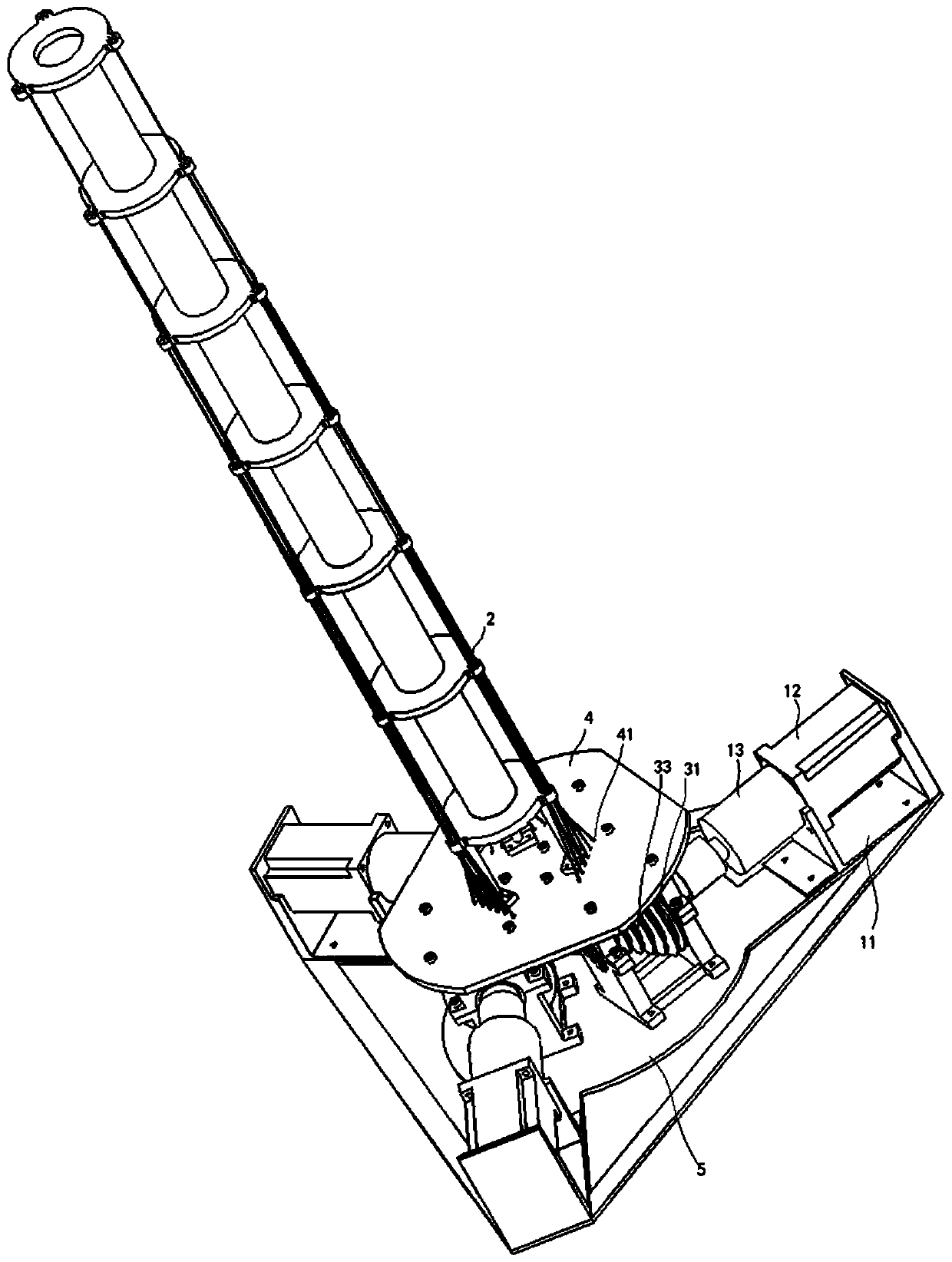

[0042] Embodiment 2 provides a multi-joint joint motion flexible mechanical arm driving device, such as figure 2 with 3As shown, it is applied to a flexible robot arm including 6 joints, wherein each joint has 3 groups of first threading holes, each group of first threading holes has at least 6 first threading holes, and the first threading holes of the same group One threading hole is centrally set around the same center point, and three sets of first threading holes are evenly distributed along the circumference of the joint; the flexible manipulator driving device for multi-joint joint motion includes three sets of drive modules 1; three sets of ropes 2, each set of ropes 2 Each includes 6 ropes 2; 3 groups of winding modules 3, each group of winding modules 3 is equipped with at least 6 winding mechanisms; in the same group of ropes 2, different ropes 2 are formed by the same group of winding modules 3 and Driven by the drive module 1, and different ropes 2 are used to d...

Embodiment 3

[0057] This embodiment 3 is a modification of the above embodiment 2. The difference lies in the six through holes 343 provided on the fixed bracket 34. These through holes 343 are matched with the wire slots 33 one by one, and the ropes 2 are inserted through these through holes. 343 more turns, such as Figure 10 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com