Automatic vehicle cleaning equipment

An automatic cleaning and equipment technology, which is applied in the direction of vehicle cleaning equipment, vehicle cleaning, vehicle exterior cleaning devices, etc., can solve the problem of not having a mechanism for reciprocating cycle cleaning, not having a mechanism for replacing or fixing cleaning cotton brushes, and not having a vehicle The top effectively cleans the dirt and other problems to achieve the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

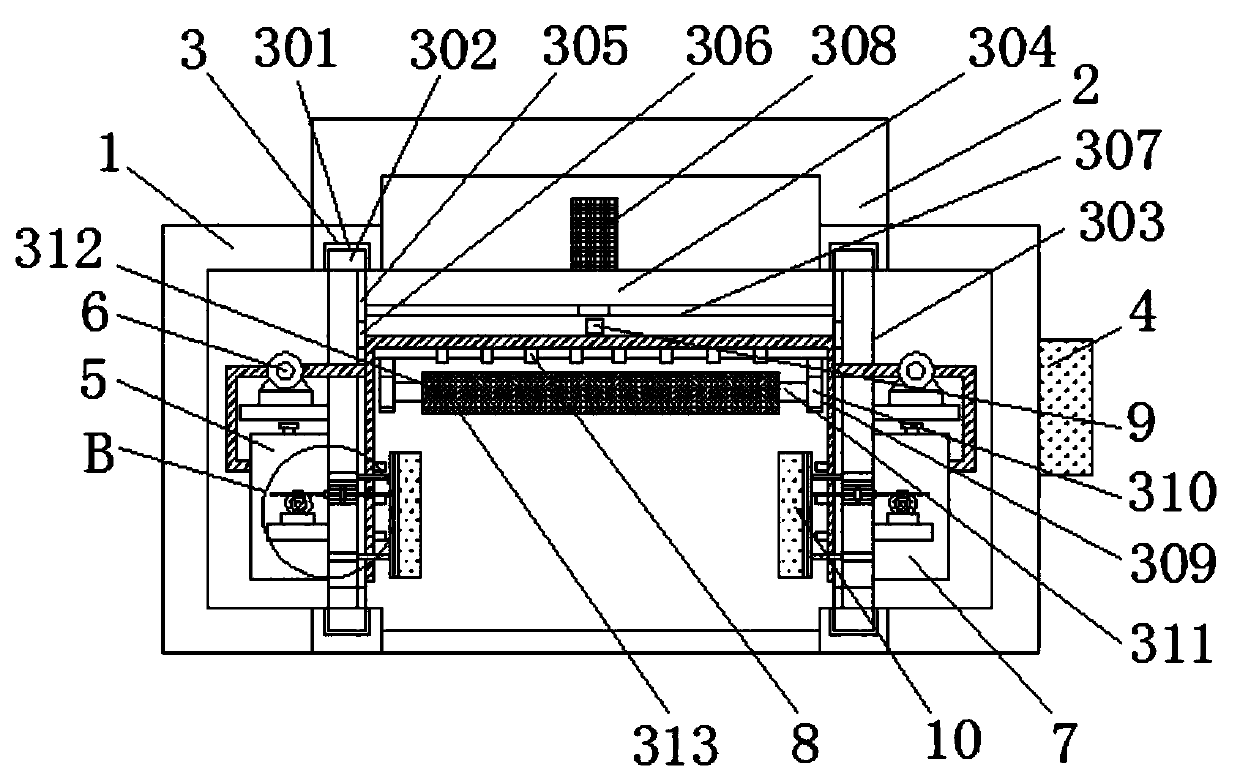

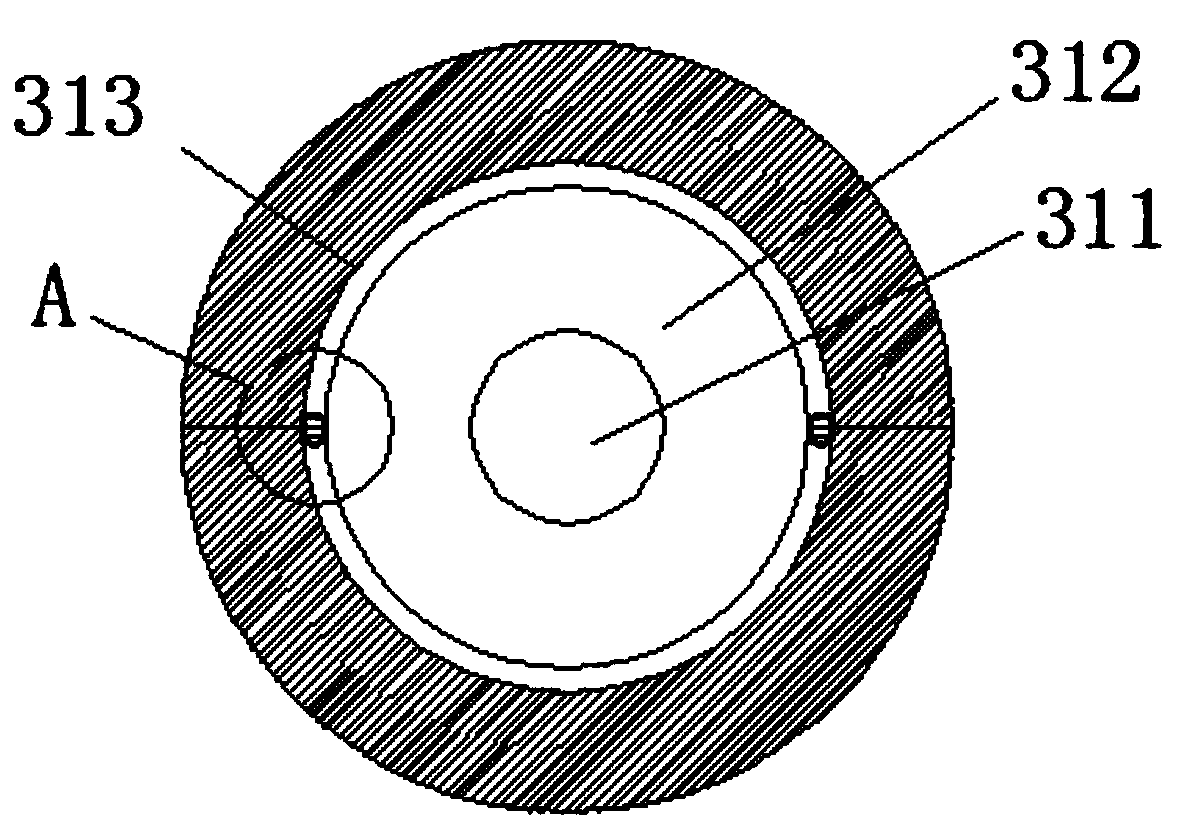

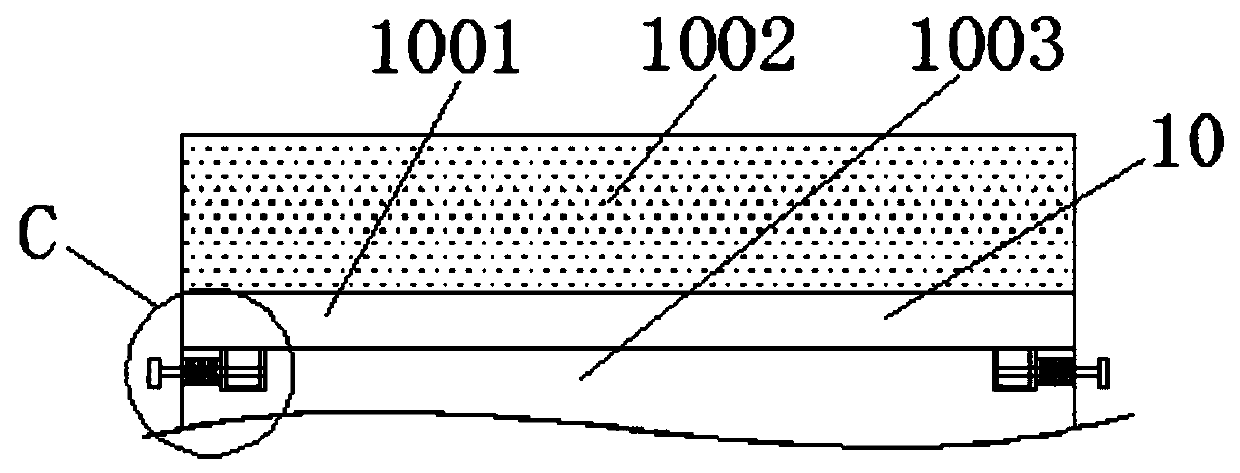

[0035] Embodiment 1: as figure 1 — Figure 6 , an automatic vehicle cleaning equipment, comprising: a support frame 1, a top plate 2, a sliding horizontal brush mechanism 3, an electromagnetic slide rail 301, an electromagnetic slider 302, a supporting plate 303, a supporting horizontal plate 304, a first chute 305, a second One slider 306, movable horizontal plate 307, electric telescopic rod 308, connecting plate 309, bearing 310, rotating shaft 311, roller 312, cleaning cotton brush 313, connecting ring 314, fixed block 315, screw 316, thumb bolt 317, control Panel 4, water tank 5, water pump 6, washing liquid tank 7, spray head 8, first sensing device 9, side brush mechanism 10, brush plate 1001, cleaning brush 1002, fixing plate 1003, connecting rod 1004, connecting block 1005, the second slider 1006, the second chute 1007, the teeth 1008, the gear 1009, the servo motor 1010, the fixed outer rod 1011, the telescopic rod 1012, the slot 1013, the post 1014, the slot 1015, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com